Ø3mm Inductives on Robot

Gripper Help Protect Fragile

Electronic Components

Miniature distance sensors,

embedded in the outward-facing

surfaces of gripper jaws, monitor

the position of potential obstructions

during travel, preventing accidents.

Ø5 and 5mm Square-section

Inductives Presence Check

Automated Hose Assembly

An array of three different inductive

sensors from Contrinex check the

presence of hose, ferrule and nut are

in position in an automated system.

MINATURE SENSORS HELP

MANIFACTURE N95 FACE MASKS

Reliability is essential in automated

production, and nowhere more than

in the hard-pressed healthcare

supply sector. At the time of the

global COVID-19 crisis.

Robust M5 Inductive Monitors

High-speed Spindle

Contrinex’s rugged miniature

inductive sensors provide presence-

sensing systems in harsh exposed

conditions, both onshore and

offshore,

xxxx xxxXX xXXXX

xxx xxxxx xxxxx x.

APPLICATION EXAMPLES

CONTRINEX CATALOGUE

PRODUCT OVERVIEW

2-PAGE FLYER

6-PAGE FLYER

DOWNLOADABLE BROCHURES

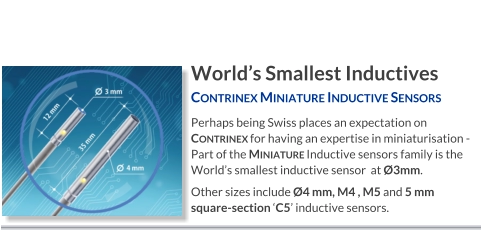

Smallest self-contained miniature inductive sensors on the market

Available in Ø3 & Ø4 mm, M4 & M5 and C5, 5 mm square-section

Industries - Machine tools, Vehicles, Assembly, Automation, Robotics,Micromechanics, and Special

purpose machinery

Temperature range -25 to +70°C or +85°C

Special versions of the ‘500’, ‘600’ & ‘700 Series’ with their benefits

‘500 Series’ Extended Distance - Up to 2.5mm sensing range

‘600 Series’ - Up to 1.5mm sensing range & up to 8,000 Hz switching

‘700 Series’ Extreme Robust - Up to 3mm sensing range & uniquely Robust

IO-Link interface makes Industry 4.0 integration easier & more powerful

FEATURES & BENEFITS

Inductive, Machine Safety, Photoelectric, Pressure, Process, Turbidity, RFID & Ultrasonic sensors from Contrinex, ReeR Safety and Satron

.

Let us help you

#MakeSenseofSensors to improve machine performance, solve applications, or reduce costs and prices using exceptional

Welcome to PLUS Automation - Experts in sensors, we are the importer, stockist and UK representative for Contrinex and Satron.

Ø3mm Inductives on Robot

Gripper Help Protect Fragile

Electronic Components

Miniature distance sensors, embedded

in the outward-facing surfaces of

gripper jaws, monitor the position of

potential obstructions during travel,

preventing accidents.

Ø5 and 5mm Square-section

Inductives Presence Check

Automated Hose Assembly

An array of three different inductive

sensors from Contrinex check the

presence of hose, ferrule and nut are in

position in an automated system.

Minature Sensors HElp

Manifacture N95 Face Masks

Reliability is essential in automated

production, and nowhere more than in

the hard-pressed healthcare supply

sector. At the time of the global COVID-

19 crisis.

Robust M5 Inductive Monitors

High-speed Spindle

Contrinex’s rugged miniature inductive

sensors provide presence-sensing

systems in harsh exposed conditions,

both onshore and offshore,

xxxx xxxXX xXXXX

xxx xxxxx xxxxx x.

APPLICATION EXAMPLES

0121 58 222 58 Sales@PLUSAutomation.co.uk

DOWNLOADABLE BROCHURES

Smallest self-contained miniature inductive sensors on the market

Available in Ø3 & Ø4 mm, M4 & M5 and C5, 5 mm square-section

Industries - Machine tools, Vehicles, Assembly, Automation,

Robotics,Micromechanics, and Special purpose machinery

Temperature range -25 to +70°C or +85°C

Special versions of the ‘500’, ‘600’ & ‘700 Series’ with their benefits

‘500 Series’ Extended Distance - Up to 2.5mm sensing range

‘600 Series’ - Up to 1.5mm sensing range & up to 8,000 Hz switching

‘700 Series’ Extreme Robust - Up to 3mm sensing range & uniquely Robust

IO-Link interface makes Industry 4.0 integration easier & more powerful

FEATURES & BENEFITS

RFID & Ultrasonic sensors from Contrinex, ReeR Safety and Satron

.

to improve machine performance, solve applications, or reduce costs and prices

using Inductive, Machine Safety, Photoelectric, Pressure, Process, Turbidity,

representative for Contrinex and Satron. Let us help you #MakeSenseofSensors

Welcome to PLUS Automation - Experts in sensors, we are the importer, stockist and UK

- Sensors

- 500 Series Extra Distance Inductives

- 600 Series Reliable Affordable Inductives

- 700 Series Uniquely Robust Inductives

- Analogue Inductives

- Double-sheet Detection Inductives

- Maritime-rated Inductives

- Miniature Inductives

- Pressure-rated Inductives

- SMART Inductives

- Swarf-immune Inductives

- Temperature-rated Inductives

- Washdown-rated Inductives

- Weld-immune Inductives

- 2-Wire Inductives

- Applications

- About Us

- Contact

- 500 Series Extra Distance Inductives

- 600 Series Reliable Affordable Inductives

- 700 Series Uniquely Robust Inductives

- Analogue Inductives

- Double-Sheet Inductives

- Maritime-rated Inductives

- Miniature Inductives

- Pressure-rated Inductives

- SMART Inductives

- Swarf-immune Inductives

- Temperature-rated Inductives

- Washdown-rated Inductives

- Weld-immune Inductives

- 2-Wire Inductives Inductives