Xxxxxx xxx xxxxxx xxxxx

Xxxxxxxxx xxxxxx xxxxx xxxx

xxxxxxx xxxxx.

Xxxxxxx xxxx xxxx

xxx xxxx xxxx xxx.

APPLICATION EXAMPLES

CONTRINEX CATALOGUE

PRODUCT OVERVIEW

CATALOGUE EXTRACT

16-PAGE FLYER

DOWNLOADABLE BROCHURES

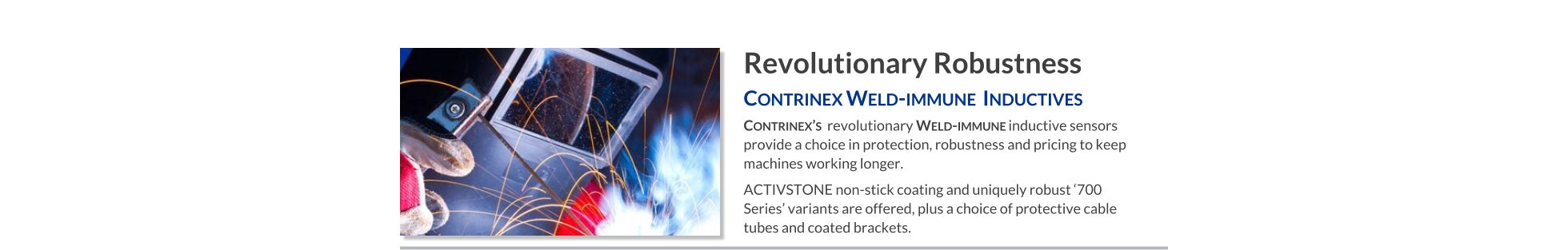

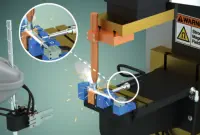

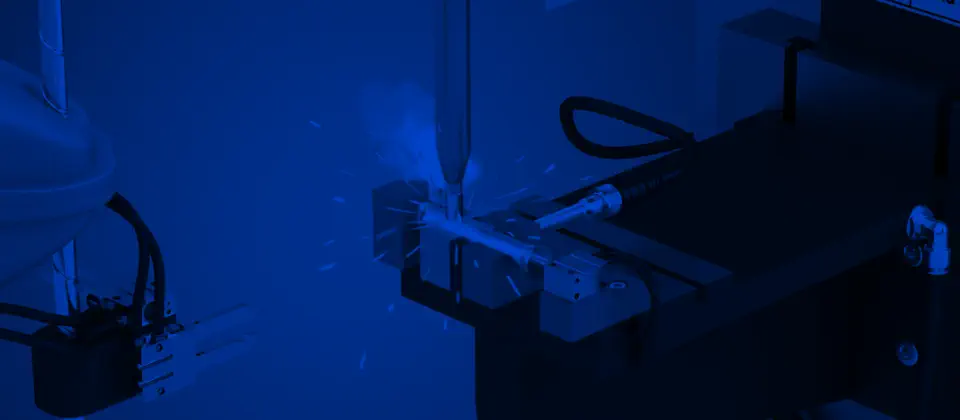

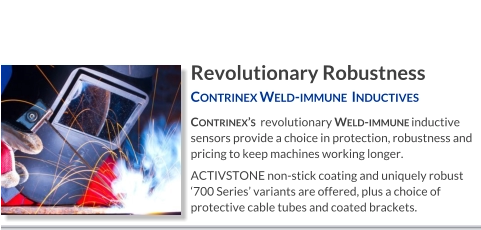

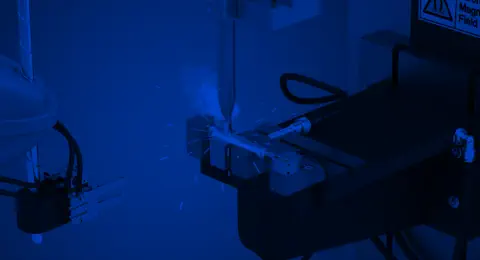

Ideal for the hostile working environments of automated welding assembly

Resist magnetic interference from medium-frequency weld fields, up to 15 kA

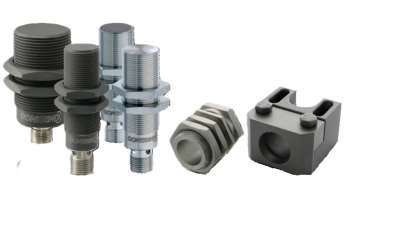

Available in sizes from M8 to M30 and C23 (20 x 30 x 8 mm) Flat-section

Optional Activestone™ coating resists weld spatter

Industries - Automotive production & supply, Welding equipment, White goods

Special versions of the ‘500’, ‘600’ & ‘700 Series’ with their benefits

‘600 Series’ - Up to 1.5mm sensing range & up to 8,000 Hz switching

‘700 Series’ Extreme Robust - Up to 3mm sensing range & uniquely Robust

IO-Link interface makes Industry 4.0 integration easier & more powerful

Large choice of cables & accessories including Activestone™ coated mounting brackets and spatter-

resistant cable

FEATURES & BENEFITS

Inductive, Machine Safety, Photoelectric, Pressure, Process, Turbidity, RFID & Ultrasonic sensors from Contrinex, ReeR Safety and Satron

.

Let us help you

#MakeSenseofSensors to improve machine performance, solve applications, or reduce costs and prices using exceptional

Welcome to PLUS Automation - Experts in sensors, we are the importer, stockist and UK representative for Contrinex and Satron.

Xxxxxx xxx xxxxxx xxxxx

Xxxxxxxxx xxxxxx xxxxx xxxx xxxxxxx

xxxxx.

Xxxxxxx xxxx xxxx

xxx xxxx xxxx xxx.

APPLICATION EXAMPLES

0121 58 222 58 Sales@PLUSAutomation.co.uk

DOWNLOADABLE BROCHURES

Ideal for the hostile working environments of automated welding assembly

Resist magnetic interference from medium-frequency weld fields, up to 15 kA

Available in sizes from M8 to M30 and C23 (20 x 30 x 8 mm) Flat-section

Optional Activestone™ coating resists weld spatter

Industries - Automotive production & supply, Welding equipment, White goods

Special versions of the ‘500’, ‘600’ & ‘700 Series’ with their benefits

‘600 Series’ - Up to 1.5mm sensing range & up to 8,000 Hz switching

‘700 Series’ Extreme Robust - Up to 3mm sensing range & uniquely Robust

IO-Link interface makes Industry 4.0 integration easier & more powerful

Large choice of cables & accessories including Activestone™ coated mounting

brackets and spatter-resistant cable

FEATURES & BENEFITS

RFID & Ultrasonic sensors from Contrinex, ReeR Safety and Satron

.

to improve machine performance, solve applications, or reduce costs and prices

using Inductive, Machine Safety, Photoelectric, Pressure, Process, Turbidity,

representative for Contrinex and Satron. Let us help you #MakeSenseofSensors

Welcome to PLUS Automation - Experts in sensors, we are the importer, stockist and UK

- Sensors

- 500 Series Extra Distance Inductives

- 600 Series Reliable Affordable Inductives

- 700 Series Uniquely Robust Inductives

- Analogue Inductives

- Double-sheet Detection Inductives

- Maritime-rated Inductives

- Miniature Inductives

- Pressure-rated Inductives

- SMART Inductives

- Swarf-immune Inductives

- Temperature-rated Inductives

- Washdown-rated Inductives

- Weld-immune Inductives

- 2-Wire Inductives

- Applications

- About Us

- Contact

- 500 Series Extra Distance Inductives

- 600 Series Reliable Affordable Inductives

- 700 Series Uniquely Robust Inductives

- Analogue Inductives

- Double-Sheet Inductives

- Maritime-rated Inductives

- Miniature Inductives

- Pressure-rated Inductives

- SMART Inductives

- Swarf-immune Inductives

- Temperature-rated Inductives

- Washdown-rated Inductives

- Weld-immune Inductives

- 2-Wire Inductives Inductives