(0121) 58 222 58 SALES@PLUSAUTOMATION.CO.UK

© 2021 - PLUS Automation Limited®

HELPING YOU #MAKE SENSE OF SENSORS

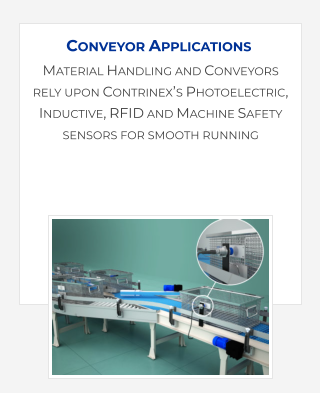

EXAMPLE APPLICATIONS

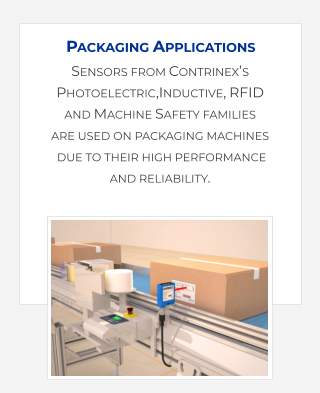

TO ILLUSTRATE THE WIDE-VARIETY OF APPLICATIONS SOLVED USING CONTRINEX SENSORS, WE HAVE POSTED A LARGE SELECTION OF EXAMPLE APPLICATIONS WHICH CAN BE SEEN BY CLICKING ON AN IMAGE. BELOW ARE A SELECTION OF SOME OF THESE APPLICATIONS:

CUSTOMER VALUES

COST-EFFECTIVE, ACTIVE SAFEGUARDING

IMPROVED WORKPLACE ERGONOMICS

INCREASED PRODUCTIVITY ARISING FROM UNIMPEDED

LOADING AND UNLOADING

INDUSTRY-STANDARD INTERFACE REQUIRES MINIMAL

MODIFICATION TO CONTROL SYSTEMS

PRODUCT ADVANTAGES

PERMANENT AUTOCONTROL NOT USUALLY FOUND ON TYPE 2

SAFETY DEVICES

IP65 AND IP67 PROTECTION

NON-CONTACT OPERATING PRINCIPLES

EXCELLENT SAFETY RATING TO EN/ISO 13849-1 CAT. 2 PL C

AND IEC 61508 SIL 1

AOPD (ACTIVE OPTOELECTRONIC PROTECTIVE DEVICE) WITH

ALUMINIUM HOUSING AND M12 CABLE CONNECTOR

CUSTOMER SOLUTION

The company’s risk assessment confirms that Type 2 AOPDs

(active optoelectronic protective devices) would ensure

appropriate operator protection. Designed for applications

where the risk has been evaluated as moderate, Safetinex IEC

61496 Type 2 light curtains from Contrinex are rated to EN/ISO

13849-1 Category 2, Performance Level PL c and IEC 61508

Safety Integrity Level SIL 1, making them ideal for the

application.

The heat-staking press is housed in an open-fronted enclosure

with clear impact-resistant walls. The light curtain has an

operating range of up to 12 metres and a resolution of 30 mm,

ideal for hand protection; it safeguards the open front area of

the press, allowing easy access when required. The protected

height is 795mm, ensuring safe operation without impeding

the operator during loading and unloading.

Manufactured with rugged extruded aluminium housings and

IP65 + IP67 protection, these units are well-suited to the

production environment and will withstand shocks and

vibrations.

Industry-standard PNP normally-open configuration allows

connection to the customer’s control system via an integral 5-

pin M12 cable connector. These units have an integrated

alignment LED and permanent autocontrol – a feature not

usually found on Type 2 safety devices.

The new sensors take up much less space than the

mechanical guards they replaced, improving workplace

ergonomics. Loading and unloading is no longer impeded,

increasing productivity while actively safeguarding operators.

Safetinex Type 2 light curtains provide a reliable and cost-

effective solution.

During semi-automated heat staking of assemblies

manufacturers use light curtains to preserve operator safety

without compromising production throughput. The active

optoelectronic protective device (AOPD), mounted directly in

front of each bench-mounted heat-press, prevents the press-

head from descending if it detects any intrusion in the

working area, halting the operating cycle immediately.

CUSTOMER APPLICATION

Heat-staking is a popular process for fastening metal parts to

plastic moldings, and is commonly used by manufacturers

during the production of sub-assemblies. At each station, an

operator loads a molding and one or more metal parts into a

slide-mounted assembly fixture. Once the components are

correctly inserted, the operator pushes the slide into position

beneath the press-head, triggering the automated heat-

staking cycle.

The heated press-head, which may reach temperatures in

excess of 350oC (660oF), descends toward the pre-positioned

components. It applies heat and pressure to specific areas of

the molding, causing a controlled thermal deformation that

creates a permanent joint between the metal parts and the

molding. Following a pre-determined dwell period, the head

returns to the raised position, ending the cycle; the operator

withdraws the slide and removes the assembly from the

fixture.

Existing mechanical safety barriers are cumbersome and

inconvenient; throughput is constrained as a result of the time

taken to open and close the guards during each cycle. The

company requires an alternative safety guard that provides

effective hand protection while allowing unobstructed loading

and unloading. It must be simple, space-saving and operate

reliably in the production environment.

CUSTOMER VALUES

HIGHLY COST EFFECTIVE SOLUTION - SUBSTANTIALLY LOWER

COST THAN OTHER DOUBLE-SHEET DETECTION SOLUTIONS

SIMPLE SETUP AND USE

ELIMINATES MACHINE JAMS, BREAKAGE OF TOOLING AND SO

ELIMINATES PRODUCTION DOWNTIME

CORROSION-RESISTANT SENSORS WITHSTAND CLEANING

PRODUCT ADVANTAGES

UNIQUE TECHNOLOGY DEFIES LIMITS OF TRADITIONAL

INDUCTIVE SENSOR TECHNOLOGY

EXTREMELY ROBUST, IMPACT AND ABRASION RESISTANT IP68/

IP69K STAINLESS-STEEL RATED HOUSING

CORROSION-RESISTANT, V2A/ AISI 304 STAINLESS-STEEL,

FOOD-COMPATIBLE BODY

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

A manufacturer of metal cans needs to ensure that the press

that applies and crimps the bottom onto the can body is fed

with only one bottom. Therefore a fast, non-contact and robust

checking mechanism is required.

CUSTOMER APPLICATION

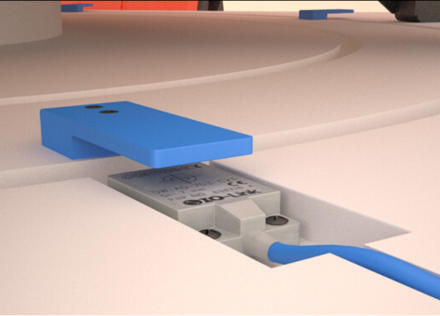

A conveyor with a stainless-steel glide plate backed by a

permanent magnet ensures that the can bottoms travel

perfectly flat on the belt which transports them to the

assembly stage. If double-bottoms are fed into the assembly

stage, damage can be done to the press, tools can be broken,

and even the press becoming jammed will cause production

downtime.

To check that only one bottom is being fed to the assembly

stage whilst they are attached magnetically to the fast-moving

belt, requires a non-contact sensing solution. The thin gauge

of steel used to produce the can bottoms (~0.33 mm thick) is

too small for the customer’s normal automatic double-sheet

detector to work reliably.

CUSTOMER SOLUTION

Contrinex’s Extreme 700 Series sensors provide a robust and

simple, cost effective solution. They utilise their Condet®

technology to detect the mass of a target by inducing a

voltage in it, whereas a traditional inductive sensor would

induce the voltage only in the target’s surface.

The stainless-steel bodied sensor (DW-Ax-70X-M12) is mounted

approximately 4 – 5 mm above the dome of a can bottom. On

its own, the 0.33mm thick steel doom presents insufficient

mass to switch the sensor at this distance, however the

presence of a second bottom piece increases target mass

sufficiently to switch the sensor.

The inductive sensor triggers a rejection shoot whenever two

bottoms are detected as being stacked together and so

provide a robust and reliable system to protect the assembly

press.

AUTOMATED ASSEMBLY ENSURES FAULT-FREE ASSEMBLY AND CONTRINEX SENSORS

ARE TRUSTED FOR THEIR RELIABILITY ESPECIALLY AS COMPLEXITY INCREASES.

CONTRINEX’S LARGE AND INNOVATIVE PRODUCT PORTFOLIOS PROVIDE CHOICE IN SENSING

TECHNOLOGIES AND HOUSING DESIGNS AND SIZES. ASSEMBLY EQUIPMENT MANUFACTURERS

TYPICALLY VALUE MINIATURISATION, ROBUSTNESS, LONG-SENSING RANGES AND PERFORMANCE.

ASSEMBLY EQUIPMENT APPLICATIONS

WATCH THE VIDEO TO SEE THE UNIQUE

ROBUSTNESS SURVIVE A HAMMERING

Conveyors deliver a continuous stream of parts to the rotary

indexing table, which transports them in sequence to each

assembly station. As the table rotates, sensors located at

precise intervals around its periphery detect its exact angular

position, bringing it to a halt once parts are correctly

positioned for the next operation.

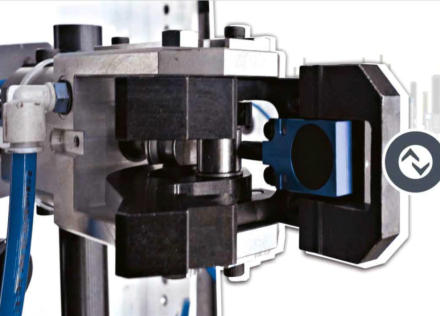

At each assembly station, automated pick-and-place

equipment add components to the assembly. Dedicated

transport mechanisms – including vacuum lifters,

electromagnetic clamps and mechanical grippers – insert

items swiftly and accurately in their designated positions.

Embeddable inductive sensors play a key role in confirming

the secure closure of custom-designed grippers before fragile,

high-value parts are lifted.

Manufactured in V4A/ AISI 316L stainless steel and rated to

IP68/ IP69K, these small inductive sensors can be fully

embedded into a steel surface such as part of the rotary table

or an assembly jig or bench, further reducing the potential for

mechanical damage.

On completion of the final assembly stage, finished PCBs are

discharged to a linear conveyor system. They travel to

subsequent processing stages, including testing and packing.

C23 Full Inox sensors mounted directly above these conveyors,

detect each unit as it passes below. This check not only

confirms the presence of the assembled item at the expected

height above the conveyor but also measures throughput by

activating a counting circuit in the customer’s control system.

Continuous operation is the norm in automated assembly

plants. However, minor adjustments or tool changes may be

required from time to time. In non-safety-critical areas, access

hatches allow maintenance technicians to carry out these

tasks without needing to interrupt production across an entire

plant. Multiple sensors, mounted at intervals around the

periphery of a hatch, ensure that appropriate warning signals

are activated whenever the opening is not fully secured.

The Contrinex C23 series of Full Inox inductive sensors have the

capability of communicating remotely with a plant-wide

control system, thanks to the implementation of the IO-Link

protocol. In a typical automated plant, each assembly line runs

continuously throughout the day, with remote diagnostics

eliminating the need for manual intervention in almost every

situation.

Designed to simplify integration, IO-Link sensors are

compatible with all IO-Link master versions, allowing set-up

and diagnostics to be conducted centrally. Interrogating a

device returns its manufacturer ID and product ID, allowing

systems integrators to determine remotely that the right

sensor is in the correct location. Contrinex C23 inductive

sensors additionally feature an on-demand self-test function

that confirms full capability at all times.

For the C23 inductive series, alternating between normally

open and normally closed functionality via remote output-

mode configuration is a standard feature of the IO-Link

protocol. Systems designers also can modify the output signal.

Delaying the switching pulse accommodates any travel time

between a sensor and its corresponding actuation point, while

stretching the pulse ensures that slave devices with lengthy

response times trigger reliably, even at high throughput rates.

Finally, each sensor provides an output-status check derived

from its factory calibration data. If the output signal from a

sensor falls outside a range that corresponds to a sensing

distance between 80% and 100% of its nominal value, an alarm

flag is triggered, highlighting the need for investigation. For

plant managers under pressure, peace-of-mind is a valuable

benefit.

The no-cost option of the industry-standard IO-Link protocol

ensures that best-in-class performance is coupled with

ultimate ease of use in even the most demanding

circumstances.

CUSTOMER VALUES

EFFICIENT, FAULT-FREE ASSEMBLY.

NO SENSOR-RELATED DOWNTIME.

DIGITAL COMMUNICATION WITHOUT NEEDING SPECIAL

CABLING.

OUTSTANDING PROCESS MONITORING & CONTROL

CAPABILITIES.

FAST, EASY SET-UP AND RECONFIGURATION.

PRODUCT ADVANTAGES

EXTREMELY ROBUST, IMPACT AND ABRASION RESISTANT IP68/

IP69K RATED HOUSING.

CORROSION-RESISTANT, V4A/ AISI 316L STAINLESS-STEEL,

FOOD-COMPATIBLE BODY ON C23 AND AVAILABLE AS AN

OPTION ON CYCLINDRICAL SENSORS.

LONG OPERATING DISTANCE OF 7MM IN A SMALL & SLIM

STAINLESS-STEEL 20X 32X 8MM HOUSING.

ROBUST, METAL-CASED INDUCTIVE PROXIMITY SENSORS

SUITABLE FOR EASY INTEGRATION

FACTOR 1 - CONSISTENT SENSING, IRRESPECTIVE OF WHETHER

THE TARGET IS STEEL OR ALUMINIUM.

RELIABLE, COMPACT VIBRATION-RESISTANT SENSORS

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

Fault-free assembly is ensured, downtime minimised and

assembly speed increased by using automated facilities for

high volume assembly. Rugged inductive sensors detect the

presence and position of equipment or components at each

stage to ensure that parts are correctly aligned and ready for

the next operation. The sensors must be accurate and

responsive. In addition, an IO-Link interface offers the

advantages of digital communication without the need for

special cabling.

CUSTOMER APPLICATION

Highly reliable automation and machine-control systems are

used to eliminate assembly faults and improve efficiency in an

assembly operation. Whilst the repetitive assembly tasks are

well-suited to being done by robots, these robots can be too

slow at picking and placing the assembled parts and therefore

a rotary indexing table is used to move the assemblies

between the robots.

The rotary indexing table speeds up the transfer of PCBs

between assembly robots and also on and off conveyors,

increasing the production throughput and reducing the

number of assembly robots required – Sensors are used to

automate these processes and these sensors must be able to

operate continuously at high speed, performing tasks

including: presence detection to initiate the cassette-change

cycle in a stack feeder; position control for a rotary indexing

table; pick-and-place gripper control; and presence monitoring

on a conveyor system.

Customer Solution

Stack-feeders deliver base plates, electrical printed circuit

boards and other planar components to the assembly lines. In

each stack-feeder, a vertical cassette holds as many as 50

individual parts and a single inductive sensor monitors the

status of each cassette. Once the final part is discharged from

the stack, the cassette moves to its end position, triggering the

sensor and initiating the cassette-change cycle.

Contrinex C23 embeddable inductive sensors, featuring a one-

piece stainless-steel housing, are both robust and highly

reliable. A 7mm sensing distance allows ample operating

clearance, minimizing the risk of mechanical collision. Their

implementation into the assembly equipment is made easier

by the choice of industry-standard PNP or NPN outputs with

either a PUR cable or an M8 pigtail connector. Additionally, IO-

Link, a standardised point-to-point serial connection protocol

for sensors and actuators, is provided at no additional cost,

offering the advantages of digital communication without the

need for special cabling, making them ideal for Industry 4

applications.

Designed for demanding applications, Contrinex’s rugged C23

inductive sensors offer best-in-class switching frequency of

180Hz and exceptional robustness including impact and

abrasion resistance, making them a versatile, cost-effective

and highly reliable solution. These uniquely robust sensors are

typically demonstrated by Contrinex as being able to

repeatedly being used to hammer in nails. Even when their

front face is dented, the sensor continues to operate correctly

CUSTOMER VALUES

RUGGED INDUCTIVES ENSURE ACCURATE POSITIONING OF

MATERIALS, ELIMINATING FAULTS

MINIATURE EXTRA-DISTANCE SENSOR FITS SAFELY &

UNOBTRUSIVELY INTO IN-LINE WELDING STATION

IMMEDIATE AVAILABILITY OF DIVERSE SENSOR RANGE

ENABLES RAPID INCREASE IN PRODUCTION CAPACITY

PROVEN TECHNOLOGY ENSURES HIGHLY RELIABLE FIT-&-

FORGET OPERATION WITH NO MANUAL INTERVENTION

PRODUCT ADVANTAGES

ROBUST, METAL-CASED INDUCTIVE PROXIMITY SENSORS

SUITABLE FOR EASY INTEGRATION

DIVERSE PORTFOLIO OFFERS EXCEPTIONAL RANGE OF SIZES

AND SENSING DISTANCES

RELIABLE, COMPACT VIBRATION-RESISTANT SENSORS

IO-LINK INTERFACE INCLUDED FOR FREE – IDEAL FOR

INDUSTRY 4

OEM equipment builders have long relied on Contrinex as a

single source of high-performance and reliable sensors for

integration within their machines. The ability to supply the

sensors from stock was also essential in this instance, as the

machine was built to manufacture essential N95 face masks.

The sensors synchronise material feeds in the machine during

the assembly process and ensure the part-completed mask is

positioned correctly. Designers specified rugged inductive

sensors with IO-Link connectivity to prevent costly machine

malfunctions.

CUSTOMER APPLICATION

Reliability is essential in automated production, and nowhere

more than in the hard-pressed healthcare supply sector. At the

time of the global COVID-19 crisis, OEM equipment builders

rushed to increase capacity for producing personal protective

equipment (PPE). Manufacturers of N95 face masks, a high-

volume item of PPE, faced unprecedented demand worldwide.

While a single N95 mask is a relatively low-cost item, fast-

moving production lines mean that any interruption to

continuous operation is disproportionately expensive. Machine

malfunctions not only cause lost production time but also

result in costly manual intervention, and must be prevented.

Purpose-built machines for manufacturing N95 masks must

dovetail several material feeds prior to assembly; they must

also ensure that part-completed masks are positioned

correctly during the process. Successive workstations

incorporate multiple position-sensing and presence-detection

sensors that monitor the status of material feeds and cutter

position, as well as checking part alignment for welding and

printing. It is highly desirable to source these devices from a

single manufacturer, minimizing spares inventory and

ensuring a common interface throughout an entire machine.

Customer Solution

OEM designers specified rugged inductive sensors from the

Contrinex Basic and Miniature ranges. Not only did the

available selection match the functional requirement exactly,

the immediate availability of all the required devices from

stock eliminated delays in ramping up capacity. All the

specified sensors feature IO-Link connectivity, providing a

single, industry-standard interface to the machine control

system.

Contrinex inductive sensors are designed with the needs of

OEMs and system integrators in mind and provide an

unobtrusive fit-and-forget solution. With a sensing distance of

4 mm, the two metal-cased M12 sensors used to monitor the

positions of the steel fabric cutter and the printing head are

robust and reliable. The M8 device that detects the feed

position of the aluminium fixing strip has a V2A stainless-steel

housing and an extended sensing distance of 2 mm, fitting

snugly in the limited space available.

The extra-distance miniature M5 sensor fitted at the welding

station has a nickel-silver housing and was selected because of

its 2.5-mm sensing distance, eliminating any danger of

accidental collision during operation. Connection to all the

specified sensors is via a PVC-sheathed cable with a 3-pin

connector or 2-metre flying lead; alternative lengths are

available.

These highly versatile sensors meet designers’ needs for

trouble-free operation using sensors from a single

manufacturer. The solution is highly reliable, cost-effective

and, critically, available without delay, allowing the immediate

increase in machine-building capacity required by the OEM

customer.

WATCH THE VIDEO TO SEE THE UNIQUE

ROBUSTNESS DEMONSTRATED

WATCH THE VIDEO OF A MINIATURE

PHOTOELECTRIC PREVENT CALCULATOR THEFT

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS, WE WILL WORK TO HELP YOU

SOLVE YOUR APPLICATIONS, IMPROVE MACHINE PERFORMANCE & RELIABILITY AND REDUCE COSTS

USING CONTRINEX’S EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

CUSTOMER VALUES

COST-EFFECTIVE, ACTIVE SAFEGUARDING

IMPROVED WORKPLACE ERGONOMICS

INCREASED PRODUCTIVITY ARISING FROM UNIMPEDED

LOADING AND UNLOADING

INDUSTRY-STANDARD INTERFACE REQUIRES MINIMAL

MODIFICATION TO CONTROL SYSTEMS

PRODUCT ADVANTAGES

PERMANENT AUTOCONTROL NOT USUALLY FOUND ON TYPE 2

SAFETY DEVICES

IP65 AND IP67 PROTECTION

NON-CONTACT OPERATING PRINCIPLES

EXCELLENT SAFETY RATING TO EN/ISO 13849-1 CAT. 2 PL C

AND IEC 61508 SIL 1

AOPD (ACTIVE OPTOELECTRONIC PROTECTIVE DEVICE) WITH

ALUMINIUM HOUSING AND M12 CABLE CONNECTOR

CUSTOMER SOLUTION

The company’s risk assessment confirms that Type 2 AOPDs

(active optoelectronic protective devices) would ensure

appropriate operator protection. Designed for applications

where the risk has been evaluated as moderate, Safetinex IEC

61496 Type 2 light curtains from Contrinex are rated to EN/ISO

13849-1 Category 2, Performance Level PL c and IEC 61508

Safety Integrity Level SIL 1, making them ideal for the

application.

The heat-staking press is housed in an open-fronted enclosure

with clear impact-resistant walls. The light curtain has an

operating range of up to 12 metres and a resolution of 30 mm,

ideal for hand protection; it safeguards the open front area of

the press, allowing easy access when required. The protected

height is 795mm, ensuring safe operation without impeding

the operator during loading and unloading.

Manufactured with rugged extruded aluminium housings and

IP65 + IP67 protection, these units are well-suited to the

production environment and will withstand shocks and

vibrations.

Industry-standard PNP normally-open configuration allows

connection to the customer’s control system via an integral 5-

pin M12 cable connector. These units have an integrated

alignment LED and permanent autocontrol – a feature not

usually found on Type 2 safety devices.

The new sensors take up much less space than the

mechanical guards they replaced, improving workplace

ergonomics. Loading and unloading is no longer impeded,

increasing productivity while actively safeguarding operators.

Safetinex Type 2 light curtains provide a reliable and cost-

effective solution.

CUSTOMER VALUES

HIGHLY COST EFFECTIVE SOLUTION - SUBSTANTIALLY LOWER

COST THAN OTHER DOUBLE-SHEET DETECTION SOLUTIONS

SIMPLE SETUP AND USE

ELIMINATES MACHINE JAMS, BREAKAGE OF TOOLING AND SO

ELIMINATES PRODUCTION DOWNTIME

CORROSION-RESISTANT SENSORS WITHSTAND CLEANING

PRODUCT ADVANTAGES

UNIQUE TECHNOLOGY DEFIES LIMITS OF TRADITIONAL

INDUCTIVE SENSOR TECHNOLOGY

EXTREMELY ROBUST, IMPACT AND ABRASION RESISTANT IP68/

IP69K STAINLESS-STEEL RATED HOUSING

CORROSION-RESISTANT, V2A/ AISI 304 STAINLESS-STEEL,

FOOD-COMPATIBLE BODY

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

A manufacturer of metal cans needs to ensure that the press

that applies and crimps the bottom onto the can body is fed

with only one bottom. Therefore a fast, non-contact and robust

checking mechanism is required.

CUSTOMER APPLICATION

A conveyor with a stainless-steel glide plate backed by a

permanent magnet ensures that the can bottoms travel

perfectly flat on the belt which transports them to the

assembly stage. If double-bottoms are fed into the assembly

stage, damage can be done to the press, tools can be broken,

and even the press becoming jammed will cause production

downtime.

To check that only one bottom is being fed to the assembly

stage whilst they are attached magnetically to the fast-moving

belt, requires a non-contact sensing solution. The thin gauge

of steel used to produce the can bottoms (~0.33 mm thick) is

too small for the customer’s normal automatic double-sheet

detector to work reliably.

CUSTOMER SOLUTION

Contrinex’s Extreme 700 Series sensors provide a robust and

simple, cost effective solution. They utilise their Condet®

technology to detect the mass of a target by inducing a

voltage in it, whereas a traditional inductive sensor would

induce the voltage only in the target’s surface.

The stainless-steel bodied sensor (DW-Ax-70X-M12) is mounted

approximately 4 – 5 mm above the dome of a can bottom. On

its own, the 0.33mm thick steel doom presents insufficient

mass to switch the sensor at this distance, however the

presence of a second bottom piece increases target mass

sufficiently to switch the sensor.

The inductive sensor triggers a rejection shoot whenever two

bottoms are detected as being stacked together and so

provide a robust and reliable system to protect the assembly

press.

ASSEMBLY EQUIPMENT

APPLICATIONS

AUTOMATED ASSEMBLY ENSURES FAULT-FREE

ASSEMBLY AND CONTRINEX SENSORS ARE

TRUSTED FOR THEIR RELIABILITY ESPECIALLY

AS COMPLEXITY INCREASES.

CONTRINEX’S LARGE AND INNOVATIVE PRODUCT

PORTFOLIOS PROVIDE CHOICE IN SENSING

TECHNOLOGIES AND HOUSING DESIGNS AND SIZES.

ASSEMBLY EQUIPMENT MANUFACTURERS TYPICALLY

VALUE MINIATURISATION, ROBUSTNESS, LONG-

SENSING RANGES AND PERFORMANCE.

Conveyors deliver a continuous stream of parts to the rotary

indexing table, which transports them in sequence to each

assembly station. As the table rotates, sensors located at

precise intervals around its periphery detect its exact angular

position, bringing it to a halt once parts are correctly

positioned for the next operation.

At each assembly station, automated pick-and-place

equipment add components to the assembly. Dedicated

transport mechanisms – including vacuum lifters,

electromagnetic clamps and mechanical grippers – insert

items swiftly and accurately in their designated positions.

Embeddable inductive sensors play a key role in confirming

the secure closure of custom-designed grippers before fragile,

high-value parts are lifted.

Manufactured in V4A/ AISI 316L stainless steel and rated to

IP68/ IP69K, these small inductive sensors can be fully

embedded into a steel surface such as part of the rotary table

or an assembly jig or bench, further reducing the potential for

mechanical damage.

On completion of the final assembly stage, finished PCBs are

discharged to a linear conveyor system. They travel to

subsequent processing stages, including testing and packing.

C23 Full Inox sensors mounted directly above these conveyors,

detect each unit as it passes below. This check not only

confirms the presence of the assembled item at the expected

height above the conveyor but also measures throughput by

activating a counting circuit in the customer’s control system.

Continuous operation is the norm in automated assembly

plants. However, minor adjustments or tool changes may be

required from time to time. In non-safety-critical areas, access

hatches allow maintenance technicians to carry out these

tasks without needing to interrupt production across an entire

plant. Multiple sensors, mounted at intervals around the

periphery of a hatch, ensure that appropriate warning signals

are activated whenever the opening is not fully secured.

The Contrinex C23 series of Full Inox inductive sensors have the

capability of communicating remotely with a plant-wide

control system, thanks to the implementation of the IO-Link

protocol. In a typical automated plant, each assembly line runs

continuously throughout the day, with remote diagnostics

eliminating the need for manual intervention in almost every

situation.

Designed to simplify integration, IO-Link sensors are

compatible with all IO-Link master versions, allowing set-up

and diagnostics to be conducted centrally. Interrogating a

device returns its manufacturer ID and product ID, allowing

systems integrators to determine remotely that the right

sensor is in the correct location. Contrinex C23 inductive

sensors additionally feature an on-demand self-test function

that confirms full capability at all times.

For the C23 inductive series, alternating between normally

open and normally closed functionality via remote output-

mode configuration is a standard feature of the IO-Link

protocol. Systems designers also can modify the output signal.

Delaying the switching pulse accommodates any travel time

between a sensor and its corresponding actuation point, while

stretching the pulse ensures that slave devices with lengthy

response times trigger reliably, even at high throughput rates.

Finally, each sensor provides an output-status check derived

from its factory calibration data. If the output signal from a

sensor falls outside a range that corresponds to a sensing

distance between 80% and 100% of its nominal value, an alarm

flag is triggered, highlighting the need for investigation. For

plant managers under pressure, peace-of-mind is a valuable

benefit.

The no-cost option of the industry-standard IO-Link protocol

ensures that best-in-class performance is coupled with

ultimate ease of use in even the most demanding

circumstances.

CUSTOMER VALUES

EFFICIENT, FAULT-FREE ASSEMBLY.

NO SENSOR-RELATED DOWNTIME.

DIGITAL COMMUNICATION WITHOUT NEEDING SPECIAL

CABLING.

OUTSTANDING PROCESS MONITORING & CONTROL

CAPABILITIES.

FAST, EASY SET-UP AND RECONFIGURATION.

PRODUCT ADVANTAGES

EXTREMELY ROBUST, IMPACT AND ABRASION RESISTANT IP68/

IP69K RATED HOUSING.

CORROSION-RESISTANT, V4A/ AISI 316L STAINLESS-STEEL,

FOOD-COMPATIBLE BODY ON C23 AND AVAILABLE AS AN

OPTION ON CYCLINDRICAL SENSORS.

LONG OPERATING DISTANCE OF 7MM IN A SMALL & SLIM

STAINLESS-STEEL 20X 32X 8MM HOUSING.

ROBUST, METAL-CASED INDUCTIVE PROXIMITY SENSORS

SUITABLE FOR EASY INTEGRATION

FACTOR 1 - CONSISTENT SENSING, IRRESPECTIVE OF WHETHER

THE TARGET IS STEEL OR ALUMINIUM.

RELIABLE, COMPACT VIBRATION-RESISTANT SENSORS

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

Fault-free assembly is ensured, downtime minimised and

assembly speed increased by using automated facilities for

high volume assembly. Rugged inductive sensors detect the

presence and position of equipment or components at each

stage to ensure that parts are correctly aligned and ready for

the next operation. The sensors must be accurate and

responsive. In addition, an IO-Link interface offers the

advantages of digital communication without the need for

special cabling.

CUSTOMER APPLICATION

Highly reliable automation and machine-control systems are

used to eliminate assembly faults and improve efficiency in an

assembly operation. Whilst the repetitive assembly tasks are

well-suited to being done by robots, these robots can be too

slow at picking and placing the assembled parts and therefore

a rotary indexing table is used to move the assemblies

between the robots.

The rotary indexing table speeds up the transfer of PCBs

between assembly robots and also on and off conveyors,

increasing the production throughput and reducing the

number of assembly robots required – Sensors are used to

automate these processes and these sensors must be able to

operate continuously at high speed, performing tasks

including: presence detection to initiate the cassette-change

cycle in a stack feeder; position control for a rotary indexing

table; pick-and-place gripper control; and presence monitoring

on a conveyor system.

Customer Solution

Stack-feeders deliver base plates, electrical printed circuit

boards and other planar components to the assembly lines. In

each stack-feeder, a vertical cassette holds as many as 50

individual parts and a single inductive sensor monitors the

status of each cassette. Once the final part is discharged from

the stack, the cassette moves to its end position, triggering the

sensor and initiating the cassette-change cycle.

Contrinex C23 embeddable inductive sensors, featuring a one-

piece stainless-steel housing, are both robust and highly

reliable. A 7mm sensing distance allows ample operating

clearance, minimizing the risk of mechanical collision. Their

implementation into the assembly equipment is made easier

by the choice of industry-standard PNP or NPN outputs with

either a PUR cable or an M8 pigtail connector. Additionally, IO-

Link, a standardised point-to-point serial connection protocol

for sensors and actuators, is provided at no additional cost,

offering the advantages of digital communication without the

need for special cabling, making them ideal for Industry 4

applications.

Designed for demanding applications, Contrinex’s rugged C23

inductive sensors offer best-in-class switching frequency of

180Hz and exceptional robustness including impact and

abrasion resistance, making them a versatile, cost-effective

and highly reliable solution. These uniquely robust sensors are

typically demonstrated by Contrinex as being able to

repeatedly being used to hammer in nails. Even when their

front face is dented, the sensor continues to operate correctly.

CUSTOMER VALUES

RUGGED INDUCTIVES ENSURE ACCURATE POSITIONING OF

MATERIALS, ELIMINATING FAULTS

MINIATURE EXTRA-DISTANCE SENSOR FITS SAFELY &

UNOBTRUSIVELY INTO IN-LINE WELDING STATION

IMMEDIATE AVAILABILITY OF DIVERSE SENSOR RANGE

ENABLES RAPID INCREASE IN PRODUCTION CAPACITY

PROVEN TECHNOLOGY ENSURES HIGHLY RELIABLE FIT-&-

FORGET OPERATION WITH NO MANUAL INTERVENTION

PRODUCT ADVANTAGES

ROBUST, METAL-CASED INDUCTIVE PROXIMITY SENSORS

SUITABLE FOR EASY INTEGRATION

DIVERSE PORTFOLIO OFFERS EXCEPTIONAL RANGE OF SIZES

AND SENSING DISTANCES

RELIABLE, COMPACT VIBRATION-RESISTANT SENSORS

IO-LINK INTERFACE INCLUDED FOR FREE – IDEAL FOR

INDUSTRY 4

OEM equipment builders have long relied on Contrinex as a

single source of high-performance and reliable sensors for

integration within their machines. The ability to supply the

sensors from stock was also essential in this instance, as the

machine was built to manufacture essential N95 face masks.

The sensors synchronise material feeds in the machine during

the assembly process and ensure the part-completed mask is

positioned correctly. Designers specified rugged inductive

sensors with IO-Link connectivity to prevent costly machine

malfunctions.

CUSTOMER APPLICATION

Reliability is essential in automated production, and nowhere

more than in the hard-pressed healthcare supply sector. At the

time of the global COVID-19 crisis, OEM equipment builders

rushed to increase capacity for producing personal protective

equipment (PPE). Manufacturers of N95 face masks, a high-

volume item of PPE, faced unprecedented demand worldwide.

While a single N95 mask is a relatively low-cost item, fast-

moving production lines mean that any interruption to

continuous operation is disproportionately expensive. Machine

malfunctions not only cause lost production time but also

result in costly manual intervention, and must be prevented.

Purpose-built machines for manufacturing N95 masks must

dovetail several material feeds prior to assembly; they must

also ensure that part-completed masks are positioned

correctly during the process. Successive workstations

incorporate multiple position-sensing and presence-detection

sensors that monitor the status of material feeds and cutter

position, as well as checking part alignment for welding and

printing. It is highly desirable to source these devices from a

single manufacturer, minimizing spares inventory and

ensuring a common interface throughout an entire machine.

Customer Solution

OEM designers specified rugged inductive sensors from the

Contrinex Basic and Miniature ranges. Not only did the

available selection match the functional requirement exactly,

the immediate availability of all the required devices from

stock eliminated delays in ramping up capacity. All the

specified sensors feature IO-Link connectivity, providing a

single, industry-standard interface to the machine control

system.

Contrinex inductive sensors are designed with the needs of

OEMs and system integrators in mind and provide an

unobtrusive fit-and-forget solution. With a sensing distance of

4 mm, the two metal-cased M12 sensors used to monitor the

positions of the steel fabric cutter and the printing head are

robust and reliable. The M8 device that detects the feed

position of the aluminium fixing strip has a V2A stainless-steel

housing and an extended sensing distance of 2 mm, fitting

snugly in the limited space available.

The extra-distance miniature M5 sensor fitted at the welding

station has a nickel-silver housing and was selected because of

its 2.5-mm sensing distance, eliminating any danger of

accidental collision during operation. Connection to all the

specified sensors is via a PVC-sheathed cable with a 3-pin

connector or 2-metre flying lead; alternative lengths are

available.

These highly versatile sensors meet designers’ needs for

trouble-free operation using sensors from a single

manufacturer. The solution is highly reliable, cost-effective

and, critically, available without delay, allowing the immediate

increase in machine-building capacity required by the OEM

customer.

WATCH THE VIDEO TO SEE THE UNIQUE

ROBUSTNESS SURVIVE A HAMMERING

WATCH THE VIDEO TO SEE THE UNIQUE

ROBUSTNESS DEMONSTRATED

WATCH THE VIDEO OF A MINIATURE

PHOTOELECTRIC PREVENT CALCULATOR THEFT

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS,

WE WILL HELP YOU SOLVE YOUR APPLICATIONS, IMPROVE MACHINE

PERFORMANCE & RELIABILITY AND REDUCE COSTS USING CONTRINEX’S

EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

During semi-automated heat staking of assemblies

manufacturers use light curtains to preserve operator safety

without compromising production throughput. The active

optoelectronic protective device (AOPD), mounted directly in

front of each bench-mounted heat-press, prevents the press-

head from descending if it detects any intrusion in the

working area, halting the operating cycle immediately.

CUSTOMER APPLICATION

Heat-staking is a popular process for fastening metal parts to

plastic moldings, and is commonly used by manufacturers

during the production of sub-assemblies. At each station, an

operator loads a molding and one or more metal parts into a

slide-mounted assembly fixture. Once the components are

correctly inserted, the operator pushes the slide into position

beneath the press-head, triggering the automated heat-

staking cycle.

The heated press-head, which may reach temperatures in

excess of 350oC (660oF), descends toward the pre-positioned

components. It applies heat and pressure to specific areas of

the molding, causing a controlled thermal deformation that

creates a permanent joint between the metal parts and the

molding. Following a pre-determined dwell period, the head

returns to the raised position, ending the cycle; the operator

withdraws the slide and removes the assembly from the

fixture.

Existing mechanical safety barriers are cumbersome and

inconvenient; throughput is constrained as a result of the time

taken to open and close the guards during each cycle. The

company requires an alternative safety guard that provides

effective hand protection while allowing unobstructed loading

and unloading. It must be simple, space-saving and operate

reliably in the production environment.