(0121) 58 222 58 SALES@PLUSAUTOMATION.CO.UK

© 2021 - PLUS Automation Limited®

HELPING YOU #MAKE SENSE OF SENSORS

--

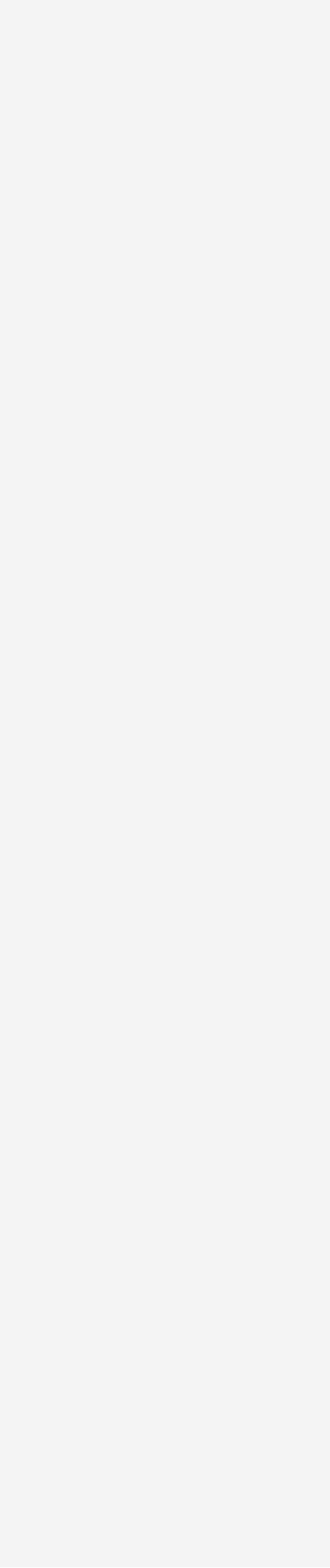

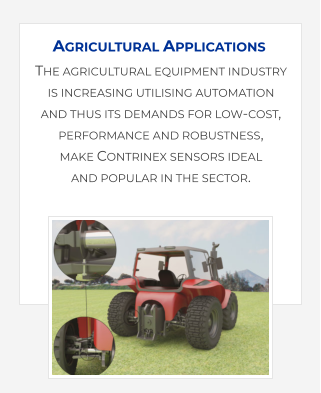

EXAMPLE APPLICATIONS

TO ILLUSTRATE THE WIDE-VARIETY OF APPLICATIONS SOLVED USING CONTRINEX SENSORS, WE HAVE POSTED A LARGE SELECTION OF EXAMPLE APPLICATIONS WHICH CAN BE SEEN BY CLICKING ON AN IMAGE. BELOW ARE A SELECTION OF SOME OF THESE APPLICATIONS:

CUSTOMER VALUES

RELIABLE, RELIABLE, REPEATABLE TESTING OF COMPLETE

TRAYS OF KNOBS IN A SINGLE CYCLE

TESTING IS COMPLETED IN STANDARD TRANSIT TRAYS WITH NO

ADDITIONAL HANDLING

IMMEDIATE IDENTIFICATION OF FAULTY ASSEMBLIES

ELIMINATION OF BATCH REJECTION BY THE CUSTOMER

PRODUCT ADVANTAGES

EXTENDED SENSING DISTANCES UP TO 12MM

EXCEPTIONAL PACKING DENSITY WITH 44MM CLEARANCE

RELIABLE SENSING OF SMALL TARGETS THROUGH PLASTIC

TRAY MATERIAL

IO- LINK CONNECTIVITY – IDEAL FOR PREVENTATIVE

MAINTENANCE AND INDUSTRY 4.0 IMPLEMENTATIONS

A plastics manufacturer tests batches of control knobs for in-

car audio systems before shipment to automotive assembly

plants; each knob contains a small metal washer that

occasionally becomes dislodged. A custom-built testing

machine tests a tray of 70 knobs in a single cycle; long-

distance inductive sensors, positioned directly below the

knobs, confirm the presence of a washer in each assembly.

CUSTOMER APPLICATION

In operation, plastic control knobs for in-car audio systems are

retained in position by small spring washers; during

manufacture, a washer is fitted to each knob after moulding. A

Portuguese manufacturer transports batches of knobs to

automotive assembly plants in transit trays, each containing

70 knobs.

Occasionally, washers are omitted or become dislodged,

resulting in rejection of entire batches of knobs by the

customer. Manual inspection of each knob is neither practical

nor cost-effective; a sensor system must test each knob in-situ

in the transit tray.

The size and position of the washers makes the task

particularly demanding. Each 10mm-diameter washer is

formed from 1mm-diameter steel wire; in a batch of knobs,

located at 45mm centres in a transit tray, washers lie more

than 10 millimetres above the sensors. The sensors must

operate reliably in close proximity to one another, sensing the

presence of the washers through the plastic tray.

Customer Solution

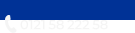

Contrinex Extra Distance inductive sensors are ideal for this

application; M18-diameter units from the Basic range operate

reliably at sensing distances up to 12mm. Quasi-embeddable

with chrome-plated brass bodies and PBTP sensing faces,

these devices allow a minimum clearance between sensors of

only 44mm, comfortably accommodating the required

spacing.

A bank of 70 sensors, mounted in a custom-built testing

fixture, aligns exactly with the positions of the knobs in the

transit tray. Locating lugs position the tray correctly and

clamps secure it during the testing cycle; checking the

presence of a washer in each of the 70 knobs is accomplished

in a few seconds and in the event that a washer is missing, the

position of the faulty knob is immediately identified.

This Contrinex inductive sensor has an industry-standard PNP

normally-open interface and an integral M12 connector,

allowing easy removal and replacement of individual sensors

for maintenance. Connection to the customer’s test

equipment is via a flexible PVC-sheathed cable.

With an unmatched combination of extended sensing

distance and exceptional packing density, Contrinex Extra

Distance inductive sensors deliver highly reliable test results.

Previously, the customer had no reliable means of testing a

complete tray of knobs in a single operation.

As part of Contrinex’s family of IO-Link sensors, the largest

range of IO-Link sensors in the World, easy access is given to

the sensor’s control and monitoring functions. This increased

connectivity enables a machine’s maintenance costs to be

reduced and system availability increased, plus easy

integration into Industry 4.0 systems.

CUSTOMER VALUES

CONTINUOUS PRODUCTION AS IN-PROCESS MEASUREMENT IS

HIGHLY ACCURATE WITH HIGH SAMPLING RATE

DEFECTS IDENTIFIED IN REAL TIME MINIMISES REJECT COSTS

NO RESTRICTIONS ON MOUNTING POSITION AS SENSORS ARE

VIBRATION-RESISTANT AND TEMPERATURE-STABLE

COMPATIBILITY WITH EXISTING IN-HOUSE SYSTEMS 0 TO 10V

LONG SENSING DISTANCE MINIMISES RISK OF MECHANICAL

DAMAGE TO THE SENSOR

PRODUCT ADVANTAGES

EXCEPTIONAL DETECTION ACCURACY, EXCELLENT

REPEATABILITY AND RESOLUTION IN THE MICRON RANGE (µM)

SAMPLING RATE OF 250HZ

CONDIST® TECHNOLOGY PROVIDES EXTENDED SENSING

RANGE ≤ 10 MM

RUGGED, VIBRATION-RESISTANT WITH METAL HOUSINGS

INDUSTRY-STANDARD 0 TO 10V ANALOGUE OUTPUTS

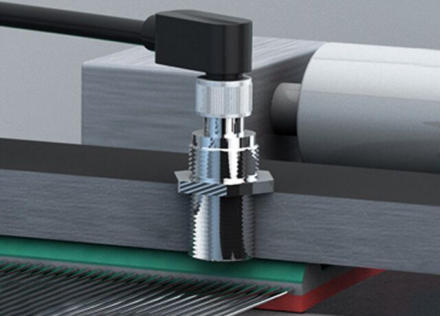

A manufacturer of industrial timing belts trusts Contrinex’s

analogue inductive sensors to measure the position of steel

reinforcing bands during continuous production.

Two long-range, high-resolution sensors, mounted above the

extruded belt profile, provide real-time positional data. The

customer’s process-control system monitors the sensor’s

analogue voltage outputs, alerting the operator and halting

production if the values are outside allowable limits.

CUSTOMER APPLICATION

To enhance the strength of industrial timing belts, steel

reinforcing wires are bonded into the belt carcass as part of a

continuous extrusion process. The distance between the

reinforcing wires and the belt teeth is a critical parameter,

influencing the accuracy of the belt’s fit and other operating

characteristics, including service life.

Engineers can check product quality at intervals by cutting

samples of extruded belts and taking optical measurements,

but this process is slow and only detects faults some time after

production is complete, leading to high reject costs.

The customer requires a real-time system with sensors that

reliable and accurately measure the position of the steel

reinforcement.

CUSTOMER SOLUTION

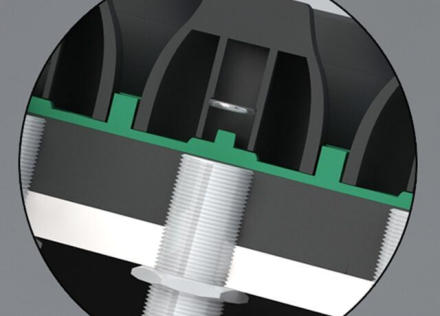

Contrinex M18-size analogue inductive sensors are ideal for this

application providing an analogue voltage output with a

sampling rate of at least 100Hz. The physical characteristics of

the belt dictate a sensing distance of up to 10 mm with micron

(µm) measurement accuracy. Contrinex’s patented Condist®

technology provides a highly stable sensing performance at

operating distances of ≤10 mm with exceptional detection

accuracy, excellent repeatability and resolution in the micron

range.

The sensors sample at 250Hz, enabling accurate measurement

of the position of the steel reinforcement in the fast moving

belt profile, and provide continuous, non-linearised 0 to 10V

analogue output signals. They are resistant to vibration and

variations in ambient temperature, allowing their positioning

immediately after the extrusion press in close proximity to the

moving belt.

Two sensors, set flush into a non-metallic plate, are mounted

directly above the surface of the belt as it runs over a guide

roller, giving a stable reference position. The lightly tensioned

belt clears the sensing face of the devices by a few tenths of a

millimetre. Connection to the customer’s control system is via

a flexible cable with an easily detachable M12 connector.

The introduction of Contrinex analogue inductive sensors

provide small, high-accuracy, ultra-reliable sensors with a low

total cost of ownership.

Rather than needing to destructively test belts to inspect the

position of the steel reinforcement and risking high reject

costs because of the infrequent nature of the sampling, the

production process is now continuously monitored.

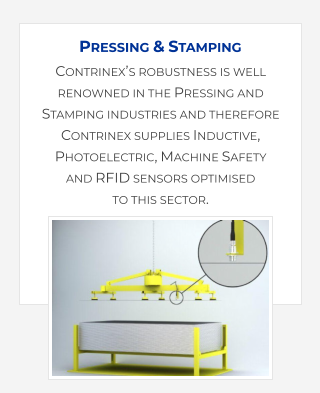

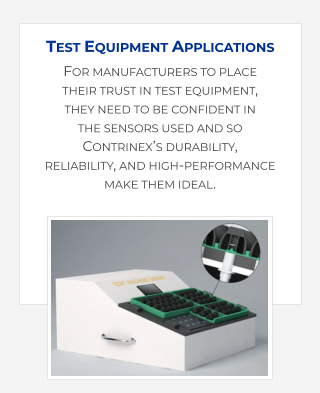

FOR MANUFACTURERS TO PLACE THEIR TRUST IN TEST AND INSPECTION EQUIPMENT,

THEY NEED TO BE CONFIDENT IN THE SENSORS THEY USE - CONTRINEX SENSOR’S

DURABILITY, RELIABILITY, AND HIGH-PERFORMANCE THEREFORE MAKE THEM IDEAL.

TEST & INSPECTION EQUIPMENT APPLICATIONS

CUSTOMER VALUES

PROVEN TECHNOLOGY TO ENSURE HIGHLY RELIABLE FIT-&-

FORGET POKA YOKE QUALITY CONTROL WITH NO MANUAL

INTERVENTION

UNOBTRUSIVE SYSTEM THAT DOES NOT IMPACT UPON THE

WELDING STATION CYCYLE TIMES

FAST & EASY SWAP OUT IN CASE OF DAMAGE TO THE SENSOR

PRODUCT ADVANTAGES

COMPACT & ROBUST, ALUMINIUM EXTRUDED HOUSING - 40 X

20.5MM)

DIVERSE PORTFOLIO OFFERS EXCEPTIONAL RANGE OF SIZES -

100 TO 2,000MM HEIGHT AND 0.9 TO 25MM RESOLUTION

FAST & EASY INTEGRATION WITH M12 CONNECTORS

LOW COST, HIGH PERFORMANCE AND LONG SENSING RANGE

During manufacture of mechanical assemblies for automotive

production, an operator uses a manually operated machine to

assemble metal parts together. After assembly the operator

drops the assembly in a transport bin ready for dispatch. As

each assembly is placed in the bin, an infra-red light detection

grid sensor detects its presence and confirms that the welding

cycle has been completed correctly

CUSTOMER APPLICATION

In an automotive 1st tier supplier manufacturing plant, an

operator loads small parts by hand onto an assembly machine

and initiates the PLC-controlled cycle. After assembly the

operator drops the completed assembly into a metal bin used

to transport parts directly to the customer.

From time to time, un-assembled parts are placed in the bin,

resulting in rejection of entire batches of assemblies by the

customer. Manual inspection of each assembly is impractical; a

sensor system must detect the presence of each item as it is

dropped into the bin and check that the corresponding

welding cycle has been completed.

The sensing system must not increase the process cycle-time

and must detect parts as they are dropped into the open bin,

which is approximately 120cm (4ft) long and 90cm (3ft) wide.

Parts are around 15cm (6in) long and a sensor with a rapid

response time is necessary to detect fast-moving items.

Customer Solution

The Contrinex DGI range of infra-red light detection grids is

well-suited for this application. Comprising separate sender-

and receiver-units and constructed with rugged one-piece

aluminium-profile housings, these versatile sensor systems are

ideal for the busy production environment.

With response times from 0.8 to 4.8 milliseconds which are

faster than safety light-curtains and a choice of resolutions

from 0.9 to 25mm dependent upon the size of the light grid,

the DGI light detection grids range exceed the demanding

customer specification for rapid response and reliable

detection of the small parts.

The 8m range between sender and receiver and their compact

design enables easy mounting at each end of the transport

bin without impeding the operator or increasing the process

cycle time.

The DGI light detection grid sender only requires a power

supply connection and the receiver features two Push-Pull

(PNP + NPN), Light-ON+ Dark-ON, 4-pin M12 outputs,

simplifying installation.

The system detects the presence of any item passing through

the light curtain and immediately interrogates the PLC to

confirm that a welding cycle has been completed since

detection of the preceding item. If no welding cycle is

registered, the system interrupts the process and sounds an

alarm, alerting the operator.

CUSTOMER VALUES

RELIABLE, REPEATABLE DETECTION OF THREE DISCRETE

PARTS IN A SINGLE OPERATION

ELIMINATION OF UNSAFE OCCURRENCES DUE TO FAULTY HOSE

ASSEMBLIES

HIGHLY COST-EFFECTIVE SOLUTION TO A PREVIOUSLY

INSOLUBLE PROBLEM

PRODUCT ADVANTAGES

SENSOR EXCEPTIONAL SENSING DISTANCES IN SMALL SENSOR

ENVELOPES

CORRECTION FACTOR OF 1.0 FOR BRASS ALLOWS EXTENDED

SENSING DISTANCE

SENSORS OPERATE IN CLOSE PROXIMITY WITHOUT

INTERFERENCE

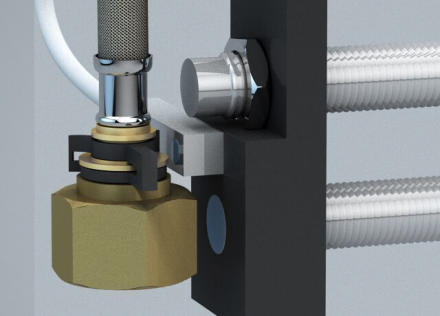

Stainless-steel-braided hydraulic hoses for water heaters

undergo over-pressure testing at the final stage of

manufacture. Before pressure is applied, a multi-sensor system

checks each hose assembly to ensure that the correct

mechanical parts have been fitted. Applying high pressure to

an incomplete assembly could result in catastrophic failure,

damaging test equipment and putting operators at risk of

injury.

CUSTOMER APPLICATION

A manufacturer of stainless-steel-braided high-pressure hoses

for water heaters carries out mandatory over-pressure testing

on every hose assembly. If either of the mechanical unions

fitted to the ends of each hose is incorrectly assembled, it will

leak under pressure.

Occasionally, a component is omitted entirely, making a hose

liable to fail catastrophically under high pressure. To avoid

damaging test equipment and endangering personnel, a

sensor system must confirm the presence of three critical

parts on each union before testing commences.

Each extra test extends the process cycle time. The customer

requires a single test fixture capable of carrying out three

presence checks concurrently, minimizing the additional cost.

The three critical parts, made from stainless steel, carbon steel

and brass, respectively, are positioned in close proximity when

assembled. Access is limited; the three sensors must be small,

yet sense these materials reliably at distances up to 6mm

(0.25in).

Customer Solution

By mounting three separate M8- and C5-sized Contrinex

inductive sensors in a single fixture, all the demands of this

application can be met in full. Each sensor is chosen for its

combination of size, sensing distance and reliable detection of

one of the three different materials

To detect the brass union nut, an M8-diameter sensor from

the Basic range (Extra Distance family) with a 4mm sensing

distance is an excellent choice. Fully embeddable with

chrome-plated nickel-silver bodies and PBTP sensing faces,

this sensor has a correction factor of 1.0 for brass,

outperforming competitors.

For detecting the steel spring, a 5mm-square-section sensor

from the Miniature range (Classics family) is an ideal option.

Embedding the sensor makes optimal use of its 1.5mm

sensing distance, and its chrome-plated brass body is well-

suited to the environment.

Finally, to ensure reliable detection of the stainless-steel collar,

an M8-diameter sensor from the Extreme range (Full Inox

family) was chosen. Its one-piece AISI 303 (V2A) stainless-steel

construction is combined with an extended operating

distance of 6mm.

Each sensor is configured with an industry-standard PNP

normally-open interface and features a hermetically sealed

cable entry. All three are connected to the customer’s control

equipment via PUR-sheathed cables. Delivering the required

detection capabilities and sensing distances in small-bodied

sensors enables Contrinex to solve a previously insoluble

problem.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS, WE WILL WORK TO HELP YOU

SOLVE YOUR APPLICATIONS, IMPROVE MACHINE PERFORMANCE & RELIABILITY AND REDUCE COSTS

USING CONTRINEX’S EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

--

CUSTOMER VALUES

RELIABLE, RELIABLE, REPEATABLE TESTING OF COMPLETE

TRAYS OF KNOBS IN A SINGLE CYCLE

TESTING IS COMPLETED IN STANDARD TRANSIT TRAYS WITH NO

ADDITIONAL HANDLING

IMMEDIATE IDENTIFICATION OF FAULTY ASSEMBLIES

ELIMINATION OF BATCH REJECTION BY THE CUSTOMER

PRODUCT ADVANTAGES

EXTENDED SENSING DISTANCES UP TO 12MM

EXCEPTIONAL PACKING DENSITY WITH 44MM CLEARANCE

RELIABLE SENSING OF SMALL TARGETS THROUGH PLASTIC

TRAY MATERIAL

IO- LINK CONNECTIVITY – IDEAL FOR PREVENTATIVE

MAINTENANCE AND INDUSTRY 4.0 IMPLEMENTATIONS

A plastics manufacturer tests batches of control knobs for in-

car audio systems before shipment to automotive assembly

plants; each knob contains a small metal washer that

occasionally becomes dislodged. A custom-built testing

machine tests a tray of 70 knobs in a single cycle; long-

distance inductive sensors, positioned directly below the

knobs, confirm the presence of a washer in each assembly.

CUSTOMER APPLICATION

In operation, plastic control knobs for in-car audio systems are

retained in position by small spring washers; during

manufacture, a washer is fitted to each knob after moulding. A

Portuguese manufacturer transports batches of knobs to

automotive assembly plants in transit trays, each containing

70 knobs.

Occasionally, washers are omitted or become dislodged,

resulting in rejection of entire batches of knobs by the

customer. Manual inspection of each knob is neither practical

nor cost-effective; a sensor system must test each knob in-situ

in the transit tray.

The size and position of the washers makes the task

particularly demanding. Each 10mm-diameter washer is

formed from 1mm-diameter steel wire; in a batch of knobs,

located at 45mm centres in a transit tray, washers lie more

than 10 millimetres above the sensors. The sensors must

operate reliably in close proximity to one another, sensing the

presence of the washers through the plastic tray.

Customer Solution

Contrinex Extra Distance inductive sensors are ideal for this

application; M18-diameter units from the Basic range operate

reliably at sensing distances up to 12mm. Quasi-embeddable

with chrome-plated brass bodies and PBTP sensing faces,

these devices allow a minimum clearance between sensors of

only 44mm, comfortably accommodating the required

spacing.

A bank of 70 sensors, mounted in a custom-built testing

fixture, aligns exactly with the positions of the knobs in the

transit tray. Locating lugs position the tray correctly and

clamps secure it during the testing cycle; checking the

presence of a washer in each of the 70 knobs is accomplished

in a few seconds and in the event that a washer is missing, the

position of the faulty knob is immediately identified.

This Contrinex inductive sensor has an industry-standard PNP

normally-open interface and an integral M12 connector,

allowing easy removal and replacement of individual sensors

for maintenance. Connection to the customer’s test

equipment is via a flexible PVC-sheathed cable.

With an unmatched combination of extended sensing

distance and exceptional packing density, Contrinex Extra

Distance inductive sensors deliver highly reliable test results.

Previously, the customer had no reliable means of testing a

complete tray of knobs in a single operation.

As part of Contrinex’s family of IO-Link sensors, the largest

range of IO-Link sensors in the World, easy access is given to

the sensor’s control and monitoring functions. This increased

connectivity enables a machine’s maintenance costs to be

reduced and system availability increased, plus easy

integration into Industry 4.0 systems.

CUSTOMER VALUES

CONTINUOUS PRODUCTION AS IN-PROCESS MEASUREMENT IS

HIGHLY ACCURATE WITH HIGH SAMPLING RATE

VIBRATION-RESISTANT AND TEMPERATURE-STABLE

DAMAGE TO THE SENSOR

REPEATABILITY AND RESOLUTION IN THE MICRON RANGE (µM)

A manufacturer of industrial timing belts trusts Contrinex’s

analogue inductive sensors to measure the position of steel

reinforcing bands during continuous production.

Two long-range, high-resolution sensors, mounted above the

extruded belt profile, provide real-time positional data. The

customer’s process-control system monitors the sensor’s

analogue voltage outputs, alerting the operator and halting

production if the values are outside allowable limits.

CUSTOMER APPLICATION

To enhance the strength of industrial timing belts, steel

reinforcing wires are bonded into the belt carcass as part of a

continuous extrusion process. The distance between the

reinforcing wires and the belt teeth is a critical parameter,

influencing the accuracy of the belt’s fit and other operating

characteristics, including service life.

Engineers can check product quality at intervals by cutting

samples of extruded belts and taking optical measurements,

but this process is slow and only detects faults some time after

production is complete, leading to high reject costs.

The customer requires a real-time system with sensors that

reliable and accurately measure the position of the steel

reinforcement.

CUSTOMER SOLUTION

Contrinex M18-size analogue inductive sensors are ideal for this

application providing an analogue voltage output with a

sampling rate of at least 100Hz. The physical characteristics of

the belt dictate a sensing distance of up to 10 mm with micron

(µm) measurement accuracy. Contrinex’s patented Condist®

technology provides a highly stable sensing performance at

operating distances of ≤10 mm with exceptional detection

accuracy, excellent repeatability and resolution in the micron

range.

The sensors sample at 250Hz, enabling accurate measurement

of the position of the steel reinforcement in the fast moving

belt profile, and provide continuous, non-linearised 0 to 10V

analogue output signals. They are resistant to vibration and

variations in ambient temperature, allowing their positioning

immediately after the extrusion press in close proximity to the

moving belt.

Two sensors, set flush into a non-metallic plate, are mounted

directly above the surface of the belt as it runs over a guide

roller, giving a stable reference position. The lightly tensioned

belt clears the sensing face of the devices by a few tenths of a

millimetre. Connection to the customer’s control system is via

a flexible cable with an easily detachable M12 connector.

The introduction of Contrinex analogue inductive sensors

provide small, high-accuracy, ultra-reliable sensors with a low

total cost of ownership.

Rather than needing to destructively test belts to inspect the

position of the steel reinforcement and risking high reject

costs because of the infrequent nature of the sampling, the

production process is now continuously monitored.

TEST & INSPECTION

EQUIPMENT APPLICATIONS

FOR MANUFACTURERS TO PLACE THEIR TRUST IN

TEST AND INSPECTION EQUIPMENT, THEY NEED TO

BE CONFIDENT IN THE SENSORS THEY USE -

CONTRINEX’S DURABILITY, RELIABILITY, AND HIGH-

PERFORMANCE THEREFORE MAKES THEM IDEAL.

CUSTOMER VALUES

PROVEN TECHNOLOGY TO ENSURE HIGHLY RELIABLE FIT-&-

FORGET POKA YOKE QUALITY CONTROL WITH NO MANUAL

INTERVENTION

UNOBTRUSIVE SYSTEM THAT DOES NOT IMPACT UPON THE

WELDING STATION CYCYLE TIMES

FAST & EASY SWAP OUT IN CASE OF DAMAGE TO THE SENSOR

PRODUCT ADVANTAGES

COMPACT & ROBUST, ALUMINIUM EXTRUDED HOUSING - 40 X

20.5MM)

DIVERSE PORTFOLIO OFFERS EXCEPTIONAL RANGE OF SIZES -

100 TO 2,000MM HEIGHT AND 0.9 TO 25MM RESOLUTION

FAST & EASY INTEGRATION WITH M12 CONNECTORS

LOW COST, HIGH PERFORMANCE AND LONG SENSING RANGE

During manufacture of mechanical assemblies for automotive

production, an operator uses a manually operated machine to

assemble metal parts together. After assembly the operator

drops the assembly in a transport bin ready for dispatch. As

each assembly is placed in the bin, an infra-red light detection

grid sensor detects its presence and confirms that the welding

cycle has been completed correctly

CUSTOMER APPLICATION

In an automotive 1st tier supplier manufacturing plant, an

operator loads small parts by hand onto an assembly machine

and initiates the PLC-controlled cycle. After assembly the

operator drops the completed assembly into a metal bin used

to transport parts directly to the customer.

From time to time, un-assembled parts are placed in the bin,

resulting in rejection of entire batches of assemblies by the

customer. Manual inspection of each assembly is impractical; a

sensor system must detect the presence of each item as it is

dropped into the bin and check that the corresponding

welding cycle has been completed.

The sensing system must not increase the process cycle-time

and must detect parts as they are dropped into the open bin,

which is approximately 120cm (4ft) long and 90cm (3ft) wide.

Parts are around 15cm (6in) long and a sensor with a rapid

response time is necessary to detect fast-moving items.

Customer Solution

The Contrinex DGI range of infra-red light detection grids is

well-suited for this application. Comprising separate sender-

and receiver-units and constructed with rugged one-piece

aluminium-profile housings, these versatile sensor systems are

ideal for the busy production environment.

With response times from 0.8 to 4.8 milliseconds which are

faster than safety light-curtains and a choice of resolutions

from 0.9 to 25mm dependent upon the size of the light grid,

the DGI light detection grids range exceed the demanding

customer specification for rapid response and reliable

detection of the small parts.

The 8m range between sender and receiver and their compact

design enables easy mounting at each end of the transport

bin without impeding the operator or increasing the process

cycle time.

The DGI light detection grid sender only requires a power

supply connection and the receiver features two Push-Pull

(PNP + NPN), Light-ON+ Dark-ON, 4-pin M12 outputs,

simplifying installation.

The system detects the presence of any item passing through

the light curtain and immediately interrogates the PLC to

confirm that a welding cycle has been completed since

detection of the preceding item. If no welding cycle is

registered, the system interrupts the process and sounds an

alarm, alerting the operator.

Stainless-steel-braided hydraulic hoses for water heaters

undergo over-pressure testing at the final stage of

manufacture. Before pressure is applied, a multi-sensor system

checks each hose assembly to ensure that the correct

mechanical parts have been fitted. Applying high pressure to

an incomplete assembly could result in catastrophic failure,

damaging test equipment and putting operators at risk of

injury.

CUSTOMER APPLICATION

A manufacturer of stainless-steel-braided high-pressure hoses

for water heaters carries out mandatory over-pressure testing

on every hose assembly. If either of the mechanical unions

fitted to the ends of each hose is incorrectly assembled, it will

leak under pressure.

Occasionally, a component is omitted entirely, making a hose

liable to fail catastrophically under high pressure. To avoid

damaging test equipment and endangering personnel, a

sensor system must confirm the presence of three critical

parts on each union before testing commences.

Each extra test extends the process cycle time. The customer

requires a single test fixture capable of carrying out three

presence checks concurrently, minimizing the additional cost.

The three critical parts, made from stainless steel, carbon steel

and brass, respectively, are positioned in close proximity when

assembled. Access is limited; the three sensors must be small,

yet sense these materials reliably at distances up to 6mm

(0.25in).

Customer Solution

By mounting three separate M8- and C5-sized Contrinex

inductive sensors in a single fixture, all the demands of this

application can be met in full. Each sensor is chosen for its

combination of size, sensing distance and reliable detection of

one of the three different materials

To detect the brass union nut, an M8-diameter sensor from

the Basic range (Extra Distance family) with a 4mm sensing

distance is an excellent choice. Fully embeddable with

chrome-plated nickel-silver bodies and PBTP sensing faces,

this sensor has a correction factor of 1.0 for brass,

outperforming competitors.

For detecting the steel spring, a 5mm-square-section sensor

from the Miniature range (Classics family) is an ideal option.

Embedding the sensor makes optimal use of its 1.5mm

sensing distance, and its chrome-plated brass body is well-

suited to the environment.

Finally, to ensure reliable detection of the stainless-steel collar,

an M8-diameter sensor from the Extreme range (Full Inox

family) was chosen. Its one-piece AISI 303 (V2A) stainless-steel

construction is combined with an extended operating

distance of 6mm.

Each sensor is configured with an industry-standard PNP

normally-open interface and features a hermetically sealed

cable entry. All three are connected to the customer’s control

equipment via PUR-sheathed cables. Delivering the required

detection capabilities and sensing distances in small-bodied

sensors enables Contrinex to solve a previously insoluble

problem.

CUSTOMER VALUES

RELIABLE, REPEATABLE DETECTION OF THREE DISCRETE

PARTS IN A SINGLE OPERATION

ELIMINATION OF UNSAFE OCCURRENCES DUE TO FAULTY HOSE

ASSEMBLIES

HIGHLY COST-EFFECTIVE SOLUTION TO A PREVIOUSLY

INSOLUBLE PROBLEM

PRODUCT ADVANTAGES

SENSOR EXCEPTIONAL SENSING DISTANCES IN SMALL SENSOR

ENVELOPES

CORRECTION FACTOR OF 1.0 FOR BRASS ALLOWS EXTENDED

SENSING DISTANCE

SENSORS OPERATE IN CLOSE PROXIMITY WITHOUT

INTERFERENCE

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS,

WE WILL HELP YOU SOLVE YOUR APPLICATIONS, IMPROVE MACHINE

PERFORMANCE & RELIABILITY AND REDUCE COSTS USING CONTRINEX’S

EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS