(0121) 58 222 58 SALES@PLUSAUTOMATION.CO.UK

© 2021 - PLUS Automation Limited®

HELPING YOU #MAKE SENSE OF SENSORS

--

EXAMPLE APPLICATIONS

TO ILLUSTRATE THE WIDE-VARIETY OF APPLICATIONS SOLVED USING CONTRINEX SENSORS, WE HAVE POSTED A LARGE SELECTION OF EXAMPLE APPLICATIONS WHICH CAN BE SEEN BY CLICKING ON AN IMAGE. BELOW ARE A SELECTION OF SOME OF THESE APPLICATIONS:

CUSTOMER VALUES

RELIABLE, EXCEPTIONAL RELIABILITY IN A HARSH OUTDOOR

ENVIRONMENT

AUTOMATIC OPERATION WITH OPTIMAL SPACE UTILISATION

ELIMINATION OF SWITCHING ERRORS DURING YEAR-ROUND

OPERATION

SIGNIFICANTLY REDUCED MAINTENANCE COSTS

PRODUCT ADVANTAGES

SENSING RANGE UP TO 12,000 MM

LONG SENSING RANGE IN SMALL SENSOR

EXCEPTIONAL RESISTANCE TO VIBRATION DURING OPERATION

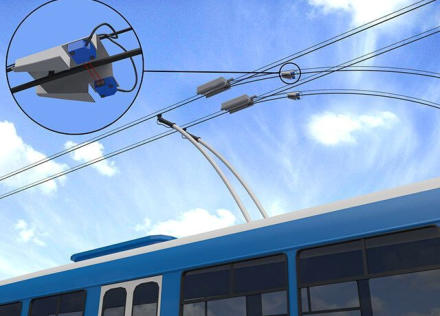

When a tram reaches a road junction, wire-switches, installed

on the overhead conductor cables, control its direction of

travel, with switches in either the default “straight-through” or

“turnout” positions. As the tram passes a switch in the turnout

position, Contrinex photoelectric sensors mounted on the

overhead cables detect the presence of the pantograph

current collector so that the control system can then reset the

switch to the default position.

CUSTOMER APPLICATION

In urban tram transportation systems, wire-switches installed

on the overhead conductor cables at road junctions, control

the direction of travel for the trams. The switches default to the

straight-through position so that when a bus approaches a

turn, the driver uses a remote trigger to change the switch to

the turnout position. After the bus completes the turn, the

switch reverts to the straight-through position.

If a triggered switch reverts to the straight-through position

prematurely, the pantagraph current collector may become

disengaged, damaging the switch. Therefore tram operators

install safety systems to prevent premature switching.

Typically, these utilise timer circuits and a predetermined delay

or mechanical sensors that rely on physical contact with the

current collector, but neither system is reliable.

A Swiss manufacturer of trolley-bus control systems requires a

highly reliable, rugged sensor system that will detect the

presence of a current collector as it passes a switch. The

system must operate with minimal maintenance and

withstand the varied weather conditions of an outdoor

environment in Switzerland and therefore they selected

Contrinex sensors.

.

Customer Solution

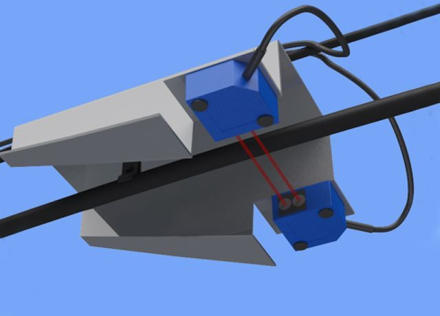

Contrinex’s C23 through-beam photoelectric sensors offer

high-performance, small size and high-stability. A purpose-

designed metal bracket, mounted above the conductor cable,

holds the transmitter and receiver units in alignment on either

side of the cable. As the pantagraph current collector passes

between the two units it breaks the beam, triggering the

sensor and returning the switch to the straight-through

position.

The C23 photoelectric sensors are virtually impervious to the

harsh, outdoor environment and their small physically size (30

x 20 x 10mm) eliminates the risk of accidental damage arising

from a mechanical collision. The rugged construction and

vacuum-encapsulated electronics within the sensor minimise

the effects of vibration, ensuring a long service life.

Each unit is connected to the trolley-bus control systems via a

PVC-sheathed cable with a hermetically sealed entry. The

receiver has an industry-standard PNP interface. The one-

piece mounting bracket allows easy removal and replacement

of the complete assembly during routine maintenance.

Operational results have been excellent and the Contrinex

sensors have proved highly reliable, eliminating switching

errors and reducing maintenance costs significantly.

These rugged miniature sensors have a sensing range up to

30m, for Through-beam applications. They are very reliable

and cost-effective with the additional benefit of offering a

range of low-cost stainless-steel mounting and protection

brackets, making them ideal for a wide variety of applications.

CUSTOMER VALUES

ELIMINATION OF HUMAN ERROR PREVENTS TRUCK BEING

DRIVEN IN AN UNSAFE CONDITION.

HIGHLY RELIABLE SENSING PERFORMANCE IN HIGHLY

DEMANDING CONDITIONS

CORROSION-RESISTANT SENSORS WITHSTAND WATER, ICE,

MUD AND SALT

HIGHLY COST-EFFECTIVE SOLUTION TO A POTENTIALLY

SERIOUS PROBLEM

PRODUCT ADVANTAGES

EXTREMELY ROBUST, IMPACT AND ABRASION RESISTANT IP68/

IP69K RATED HOUSING.

CORROSION-RESISTANT, V2A/ AISI 304 STAINLESS-STEEL,

FOOD-COMPATIBLE BODY.

LONG OPERATING DISTANCE OF 7MM IN A SMALL & SLIM

STAINLESS-STEEL 20X 32X 8MM HOUSING.

ROBUST, METAL-CASED INDUCTIVE PROXIMITY SENSORS

SUITABLE FOR EASY INTEGRATION

FACTOR 1 - CONSISTENT SENSING, IRRESPECTIVE OF WHETHER

THE TARGET IS STEEL OR ALUMINIUM.

RELIABLE, COMPACT VIBRATION-RESISTANT SENSORS

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

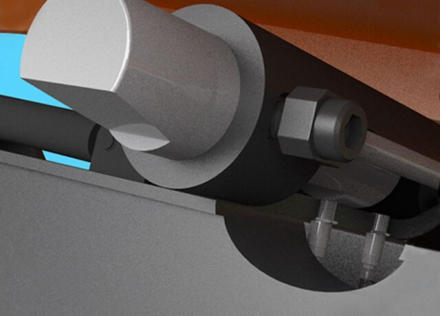

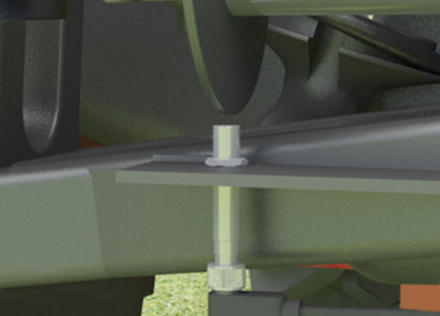

Hook loader trucks utilise a hydraulic system for loading and

unloading a demountable container. Once the container is

correctly positioned on the vehicle’s load bed, interlocks

engage with its base, securing it in position. Contrinex’s

rugged sensor systems detect full engagement of the

interlocks, ensuring the truck is safely loaded prior to driving

away. Therefore, the sensors must be mechanically robust and

able to withstand harsh outdoor conditions.

CUSTOMER APPLICATION

A specialist vehicle builder manufactures hydraulic hook-lift

systems for commercial trucks. A hook loader truck employs a

series of hydraulic rams to hook, lift and pull a demountable

container onto the vehicle’s load bed; a full container may

weigh up to 30 tons.

Hook loader trucks operate all year round, often in harsh

environments such as demolition and construction sites.

Hook-lift systems are typically semi-automated. The driver

positions the truck, engages the hook with the container and

initiates the lifting sequence. Once the container is pulled onto

the load bed, two interlock mechanisms, mounted on the

truck chassis, actuate and engage with the container body.

Once the interlocks are fully engaged, the container is secure

and the truck may be driven safely.

A highly reliable sensor system must detect the position of the

interlocks, ensuring that they are fully engaged before the

truck drives away. Sensors must be robust and must withstand

water, mud, dirt and ice. They may also be subject to

mechanical shock and vibration.

CUSTOMER SOLUTION

Rugged Full stainless-steel inductive sensors from the

Contrinex Extreme 700 Series are designed for demanding or

even exceptionally demanding environments, making them

ideal for this application. Highly reliable and IP68 / IP69K rated,

these embeddable units feature one-piece V2A (AISI 304)

stainless-steel construction with vacuum-encapsulated

electronics, making them well suited to the hostile operating

conditions.

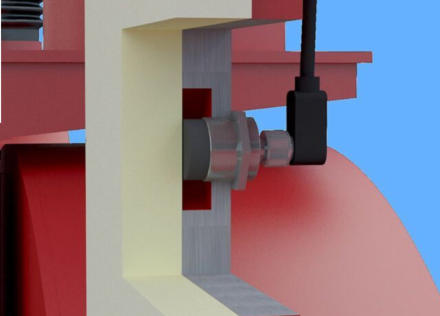

During operation, a double-ended ram drives a pair of

interlock bolts into position. On either side of the truck, two

M18-diameter sensors are mounted in the wall of each bolt

housing; one detects the bolt as it reaches the fully engaged

position; the other detects it in the fully retracted position. A

second ram drives a rotating lock mechanism to engage with

the vehicle chassis; a further two sensors detect the position of

a cam on the locking shaft as it rotates.

Each sensor is configured with an industry-standard PNP

normally-open interface, and connection to the truck’s

hydraulic control system is via an integral M12 connector and

PUR-sheathed cable. This allows easy removal and

replacement during routine maintenance.

CUSTOMER VALUES

SAFE, RELIABLE PERFORMANCE IN A DEMANDING OUTDOOR

ENVIRONMENT

NO LIKELIHOOD OF ACCIDENTAL DAMAGE ARISING IN

OPERATION

COST-EFFECTIVE SOLUTION, MAINTENANCE FREE

PRODUCT ADVANTAGES

CORROSION-RESISTANT STAINLESS-STEEL SENSOR RATED TO

IP68 AND IP69K

COST-EFFECTIVE HIGH-PERFORMANCE SENSOR WITH

EXCEPTIONAL RELIABILITY

BEST-IN-CLASS 20MM SENSING DISTANCE IN M30-DIAMETER

HOUSING

CUSTOMER SOLUTION

Contrinex inductive sensors are robust, reliable and offer

extended sensing distances; the Full Inox Extreme range is

ideal for this application. A one-piece M30-diameter stainless-

steel body and vacuum-encapsulated electronics make this

device particularly suitable for the mechanically demanding

environment, and the sensing distance of 20mm eliminates

any possibility of accidental collision in operation.

A metal bracket is mounted externally on the actuating

mechanism for the upper forks; the embeddable sensor is

mounted immediately adjacent to one of the forks and detects

the position of the actuating arm as it drives the fork into the

vertical position. The AISI 303/V2A stainless-steel housing and

sensing face are corrosion-resistant and impervious to water

ingress; the sensor is IP68- and IP69K-rated.

Configured with an industry-standard PNP normally-open

interface, the Contrinex M30 Extreme sensor connects to the

forklift’s lower-fork tilt-control systems via a flexible PUR-

sheathed cable. A sealed cable entry ensures fit-and-forget

capability during extended periods of operation in an outdoor

environment.

The Full Inox inductive sensor detects the vertical position of

the forklift’s upper forks effectively and repeatably, ensuring

safe, reliable operation of the unloading system. Contrinex

inductive sensors deliver a cost-effective solution that satisfies

the customer’s requirements for extreme robustness and

extended sensing distance.

A container manufacturer uses a modified forklift, fitted with

two sets of forks, for unloading bulk cargo. The lower forks

support the container while the upper forks control the lid.

When unloading, the lid opens and the lower forks rotate,

tipping out the contents. A robust inductive sensor senses the

position of the lid, ensuring it opens fully before emptying.

CUSTOMER APPLICATION

Containers are often used when transporting bulk cargo,

including wood chip and biomass, by rail. A manufacturer of

bulk-cargo containers has developed an innovative unloading

system that uses only a modified forklift, eliminating the need

for specialist handling equipment.

The forklift has two pairs of lifting forks. The main forks,

mounted conventionally, support the weight of the container

as it is unloaded from a freight wagon; a second pair, mounted

vertically above the lower pair, opens and closes the lid of the

container. During opening, the upper forks lift the lid a short

distance before tilting it vertically, leaving the top of the

container completely unobstructed.

The lower forks then rotate about a horizontal axis, tilting the

container end-over-end and tipping the contents out. A robust

and reliable sensor system is required to detect the vertical

position of the lid before rotation begins. An extended sensing

distance is essential to eliminate the possibility of mechanical

damage.

CUSTOMER VALUES

RELIABLE, CONTINUOUS SPEED MONITORING IN HARSH

ENVIRONMENT

FIT-AND-FORGET SENSOR SOLUTION

EFFICIENT, COMPACT DESIGN POSSIBLE FOR MOBILE TURNING

MACHINE

NO SENSOR-RELATED DOWNTIME• NO REPAIR COSTS THANKS

TO EXCEPTIONALLY LONG SENSOR LIFE

PRODUCT ADVANTAGES

EXTREMELY ROBUST, IMPACT AND ABRASION RESISTANT IP68/

IP69K RATED HOUSING.

CORROSION-RESISTANT, V4A/ AISI 316L STAINLESS-STEEL,

FOOD-COMPATIBLE BODY.

LONG OPERATING DISTANCE OF 7MM IN A SMALL & SLIM

STAINLESS-STEEL 20X 32X 8MM HOUSING.

ROBUST, METAL-CASED INDUCTIVE PROXIMITY SENSORS

SUITABLE FOR EASY INTEGRATION

FACTOR 1 - CONSISTENT SENSING, IRRESPECTIVE OF WHETHER

THE TARGET IS STEEL OR ALUMINIUM.

RELIABLE, COMPACT VIBRATION-RESISTANT SENSORS

IO-LINK INTERFACE INCLUDED FOR FREE – IDEAL FOR

INDUSTRY 4

Agriculture is using increasingly complex automation in its

machinery and an example application is in composting

machines. Contrinex’s uniquely robust V4A/ 316L stainless-steel

sensors are relied upon for operating reliably in the

challenging environment of the inside of the machine’s drive

rotor. Withstanding dust, humidity and high temperatures, the

sensors enable the machine to provide the fast drying of

materials and optimal decomposition with reliable sanitisation

being ensured.

CUSTOMER APPLICATION

The efficient turning of organic materials – loosening, lifting

and aerating – is vitally important in industrial composting.

Special mobile equipment ensures fast drying of materials,

optimal decomposition and reliable sanitisation, processing

between 500 and 6800 cubic metres of earth per hour.

A manufacturer has introduced machine speed monitoring by

sensor. A sensor located in the rotor counts the passing teeth

of a rotating mechanical disk. From the number of teeth per

second, the controller then calculates the final speed.

Perfect sensor operation is required under these particularly

harsh conditions. In addition to permanent vibration and

shaking, the inductive sensor is also constantly exposed to

dust, moisture, and temperatures from 70 to 80°C (158 to

176°F). Since the location of the sensor in the rotor is hard to

access, the sensor must be very durable and low maintenance

to avoid time-consuming repairs.

CUSTOMER SOLUTION

Contrinex inductive sensors from the FULL INOX family,

Washdown range, are perfect for this application. Made from a

single piece of V4A stainless steel, including the sensing face,

they have no covers, caps or welding seams and are the most

robust inductive sensors on the market. They resist shock,

vibration, impact and abrasion and almost any exposure to

dirt, gases, or liquids such as oil, water and cleaning agents.

Functionally stable at temperatures from -25 to +85°C (-13 to

185°F), they are also insensitive to core breakage.

Thanks to the long operating distances of these sensors (three

times greater than the norm) a compact and efficient design

was possible using the M12 size. A long operating distance

allows the sensor to be mounted well away from the rotating

disk’s passing teeth. Setup is also straightforward, as

installation tolerances are less critical. A sensor version with

plug connector was chosen to allow speedy replacement if

necessary.

CUSTOMER VALUES

MAXIMUM VEHICLE UTILISATION WITH FEWER CONSTRAINTS

ON OPERATIONS

REAL-TIME INDICATION OF BEARING CONDITION AND WEAR

RATE

REDUCED MAINTENANCE COSTS WITH MINIMAL INCIDENCE OF

BREAKDOWNS

RELIABLE OPERATION IN A HIGHLY DEMANDING AND HARSH

ENVIRONMENT

PRODUCT ADVANTAGES

ANALOGUE DEVICE WITH EXTENDED 40MM SENSING RANGE

SMALL PHYSICAL SIZE (LESS THAN 50MM LENGTH)

EXCEPTIONAL ACCURACY AND RESOLUTION IN THE MICRON

RANGE

LONG LIFE, ESPECIALLY IN APPLICATIONS WITH TEMPERATURE

FLUCTUATIONS AND VIBRATIONS

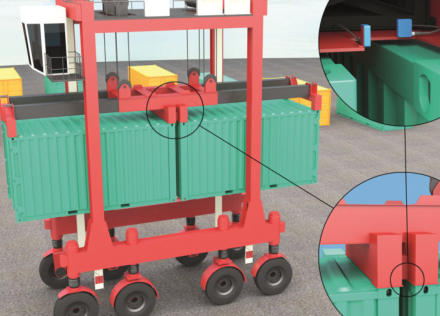

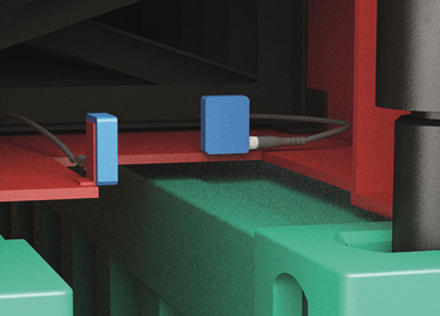

Busy container seaports rely upon the ‘24/7’ operation of

specialist container-handling vehicles called Straddle Carriers

for loading, unloading and stacking containers. Often located

at ports, being beside the sea can mean that they have to work

in an aggressive and corrosive environment, requiring

frequent maintenance.

Because traditional, interval-based maintenance schedules are

not optimally efficient, condition-based intervention systems

which minimise the risk of breakdown, are popular. European

port operators therefore frequently rely upon Contrinex’s

rugged, analogue-output inductive sensors to monitor

components with a high risk of premature failure, maximising

vehicle utilisation and reducing maintenance costs.

CUSTOMER APPLICATION

A fleet of straddle carriers services a busy container port,

operating round the clock in a highly aggressive environment.

Frequent maintenance is necessary, but traditional, interval-

based maintenance schedules are not always optimal.

Condition-based intervention minimises the risk of

breakdowns, while imposing fewer constraints on day-to-day

operation; it also incurs cost only when necessary.

As a carrier moves over a container, a central spreader beam

lowers and locks onto the four corner fittings of the container.

Plain plastic bearings on the carrier legs guide the container as

it is raised; there is significant contamination from dirt and

other debris. Bearings wear rapidly in the all-weather

operating conditions.

A condition-monitoring system must measure bearing

thickness, repeatably and accurately, in realtime and with µm

resolution. Sensors must operate reliably in the harsh

environment with a minimum rating of IP67. Sensor length

must not exceed 70mm and a minimum sensing range of

30mm is mandatory.

CUSTOMER SOLUTION

Contrinex’s Analogue Inductive sensors, which feature ‘Extra

Distance’ technology are ideal for this demanding application.

These M30-diameter metal-bodied devices are IP67-rated and

provide an analogue voltage (0 to 10 volt) or current (4 to

20mA) output. The sensors are less than 50mm long with a

40mm sensing range, comfortably exceeding the specified

requirement.

A mild steel mounting plate, fixed immediately behind the

plastic bearing, locates each sensor with its sensing face in

contact with the rear surface of the bearing. As a container

passes over the front face of the bearing, the sensor measures

the distance to the metal container wall, and thus the bearing

thickness. Data is collected in real time with exceptional

accuracy and resolution in the micron range.

Data passes to on-board computers mounted on each carrier;

connection is via a flexible cable with an easily detachable M12

connector. At intervals, carriers transmit data wirelessly to a

central processor for detailed analysis.

The output gives a clear indication of the condition and wear

rate of each bearing, identifying any carrier requiring

maintenance. Consequently, the port operator has the means

to develop a genuine commercial advantage by eliminating

compromise from day-to-day operating processes

CUSTOMER VALUES

UNINTERRUPTED PRODUCTION AS POSITIONAL

IDENTIFICATION IS HIGHLY RELIABLE.

NO RISK OF SKEWING AS MOVEMENT OF THE MACHINE

STRUCTURE IS SYNCHRONISED.

ELIMINATION OF COLLISION DAMAGE BECAUSE OF SENSING

DISTANCE UP TO 45MM.

PRODUCT ADVANTAGES

PASSIVE RFID TRANSPONDER TAGS REQUIRE NO POWER

SOURCE AND MINIMAL MAINTENANCE.

RUGGED RFID TRANSPONDER TAGS WITH NYLON OR ALL-

METAL HOUSINGS SEALED TO IP67.

CONIDENT® TECHNOLOGY PROVIDES EXTENDED SENSING

RANGE ≤ 45MM.

READ/WRITE UNITS INTERFACE WITH A CHOICE OF INDUSTRY-

STANDARD CONTROL SYSTEMS OR IO-LINK

CUSTOMER SOLUTION

Contrinex high-frequency RFID read/write modules and

30mm-diameter RFID transponder tags are ideal for this

application. Rated up to IP67, the M30-diameter read/write

modules have PBTP sensing faces and V2A stainless-steel

housings, making them ideal for the demanding environment.

The ConIdent® passive transponders require no internal power

source and, with PBTP synthetic housings, have the same IP67

rating. The selected combination provides read/write distances

of up to 45mm (nearly 2 in), ideal for the specified operating

conditions. Tags are mounted at one-meter intervals along

each travel rail, each programmed with a unique identification

number.

As the machine passes a tag, the read/write module reads its

identification number at high speed; this is transmitted via a

PROFIBUS DP interface to the customer’s control system. A

simple look-up table confirms the location of the tag and thus

the position of the machine, allowing movement of both sides

of the structure to be synchronized without skewing.

Operation is independent of the direction of travel.

Contrinex ConIdent® RFID devices allow accurate and highly

reliable sensing of machine position and the long sensing

distance avoids any risk of collision damage. The customer

enjoys extended service life and robustness not available from

alternative position-detection systems, together with excellent

value for money

A manufacturer of bulk material-handling equipment uses

Contrinex Radio Frequency IDentification (RFID) technology to

sense the position of a large rail-mounted reclamation-

conveyor operating in a hot, dusty environment. A pair of read-

write modules, mounted on the machine structure,

interrogates a series of RFID tags, positioned at one-meter

intervals along each travel rail. The control system identifies

each tag individually and determines the exact position of the

machinery.

CUSTOMER APPLICATION

During surface-mining operations, large mobile reclamation

machines are used to recover bulk materials. On each

machine, a bucket-wheel excavator collects material and

deposits it onto a conveyor. As an area is cleared of material,

the machine moves along parallel steel travel rails to the next

area, allowing continuous operation without interruptions for

machine repositioning.

The distance between the travel rails is around 100 metres (300

ft) and travel speeds may reach 2m/sec (4.5 mph). If machine

movement along the two rails is not controlled accurately, the

two sides of the structure become misaligned, causing the

machine to skew. In this event, production is halted while the

machine is realigned; in the worst case, costly damage occurs.

A sensing system is required that detects the position of each

side of the machine structure accurately and reliably along the

entire length of the travel rails, allowing coordinated control of

the drive systems. Sensors must accommodate up to 10mm

lateral movement of the machine structure across either rail

and must withstand the hot, dusty environment of a desert

climate.

I

CUSTOMER VALUES

NON-CONTACT, ALL-ELECTRONIC DEVICE WITH SENSING

RANGE UP TO 500MM.

LARGE SENSING RANGE AVAILABLE IN A PHYSICALLY SMALL

SENSOR.• EXCEPTIONAL RESISTANCE TO EXTREME VIBRATION

DURING OPERATION.

OPTIMAL SPACE UTILISATION WITH LITTLE OR NO RELIANCE

ON OPERATOR INVOLVEMENT

PRODUCT ADVANTAGES

ELIMINATION OF CALIBRATION ERRORS DURING NORMAL

OPERATION

LARGE SENSING RANGE AVAILABLE IN PHYSICALLY SMALL

SENSOR

PROVIDES RELIABLE, REPEATABLE SENSING IN DEMANDING

OPERATING CONDITIONS

At busy container seaports, purpose-designed container-

handling vehicles called Straddle Carriers, operate around the

clock, loading, unloading and stacking containers. Space

utilisation is increasingly important and correctly identifying

the size of container picked for each lift is essential for

efficiency.

Contrinex photoelectric sensors have been fitted to the

Straddle Carriers to detect the container size and eliminate the

need for drivers to carry out identification checks, saving time

and avoiding errors.

CUSTOMER APPLICATION

A fleet of straddle carriers, purpose-designed container-

handling vehicles, services a busy French container port. As a

straddle carrier moves over a container, a central lifting beam

lowers and locks onto the corner castings of the container;

each lift comprises either a single 40-foot container or two 20-

foot containers.

Optimal utilisation of storage space is essential; correctly

identifying the size of container picked for each lift is vital.

Fitting carriers with sensors that detect the size and type of

containers at the time of lifting eliminate the need for drivers

to carry out identification checks, saving time and avoiding

errors.

The original mechanical sensors proved unreliable, losing

calibration when subjected to continuous vibration during

normal operation. Although the scheduled maintenance

interval for each vehicle is 1,000 hours, mechanical sensors

required recalibration at intervals of no more than two or three

days. A highly stable replacement sensor system was required.

CUSTOMER SOLUTION

Highly stable, non-contact, all-electronic units from the

Contrinex range of photoelectric sensors provide a reliable and

cost-effective alternative. The moulded-resin sensor casings,

fitted with coated-plastic sensing faces, are IP67 rated, making

them virtually impervious to the harsh, salt-laden environment

of a busy container port. Connection to the vehicle’s control

systems is via an integral M12 connector and PVC-sheathed

cable, allowing easy removal and replacement during routine

maintenance.

To confirm the size of the container, two pairs of diffuse

sensors with background suppression are mounted centrally

on each lifting beam. As the lifting beam descends, one sensor

from each pair detects the presence or absence of corner

castings at the central lifting points, while the other detects

the presence or absence of the gap between two 20-foot

containers. The combination of the two eliminates incorrect

identification in the unlikely event that the first sensor returns

a false-positive signal from a 40-foot container.

A physically small housing and long sensing distances

eliminate the risk of accidental damage arising from a

mechanical collision, while rugged industry-standard housings

and vacuum-encapsulated electronics minimise the effects of

vibration.

Operational results have been excellent; the new Contrinex

sensors have eliminated calibration errors and reduced

maintenance costs significantly.

A range of multi-purpose off-road tractors allows the driver to

choose between two-wheel or four-wheel steering. When

selecting two-wheel steering using the front wheels only, the

rear axle is locked in the straight-ahead position. Before the

axle is locked, rugged inductive sensors from Contrinex detect

the straight-ahead position accurately and reliably, ensuring

precise alignment of the tractor’s steering geometry.

CUSTOMER APPLICATION

Modern multi-purpose off-road utility vehicles are

exceptionally versatile, offering four-wheel drive and both front

and rear-wheel steering. Reliable operation all year round, on

all types of terrain and in all weather conditions, is essential as

typical tasks include bulk-load transportation and agricultural

engineering.

Extreme conditions often demand increased manoeuvrability;

for maximum control, the driver can engage four-wheel

steering when required. When reverting to the default two-

wheel steering configuration, the rear axle must be locked in

the straight-ahead position to prevent misalignment of the

rear wheels.

A rugged, reliable and accurate sensor system is required to

detect the straight-ahead position of the rear axle before it is

locked. The sensor must withstand significant mechanical

shock and vibration and must also be impervious to water

ingress. Additionally, it should accommodate the extremes of

temperature experienced during all-year-round operation.

CUSTOMER VALUES

RELIABLE, REPEATABLE SENSING PERFORMANCE IN

DEMANDING OPERATING CONDITIONS

FIT-AND-FORGET OPERATION WITH MINIMAL MAINTENANCE

TECHNICALLY ELEGANT, COST-EFFECTIVE SOLUTION

REQUIRING MINIMAL RE-ENGINEERING

PRODUCT ADVANTAGES

2MM SENSING DISTANCE ELIMINATES THE POSSIBILITY OF

ACCIDENTAL DAMAGE TO THE SENSOR

RUGGED, ROBUST STAINLESS-STEEL SENSOR WITH INTEGRAL

M8 CONNECTOR

AFFORDABLE HIGH-PERFORMANCE SENSOR WITH

EXCEPTIONAL RELIABILITY - FIT-AND-FORGET OPERATION

WITH MINIMAL MAINTENANCE

Configured with an industry-standard PNP normally-open

interface, the sensor features an integral M8 connector and

connects to the vehicle’s central controller via a flexible PVC-

sheathed cable. Adding the sensor requires minimal

modification to the vehicle’s control systems, and

maintenance is simple and speedy.

The sensor detects the straight-ahead position of the vehicle’s

rear axle repeatably and accurately, ensuring correct, reliable

engagement of two-wheel steering. Contrinex inductive

sensors provide the customer with a cost-effective fit-and-

forget solution to a challenging problem.

CUSTOMER SOLUTION

Inductive sensors from the Contrinex ‘Basic’ range are rugged,

reliable and accommodate the required extremes of

temperature; with an M8-sized sensor being ideal for this

application.

A V2A/AISI 303 stainless-steel body and vacuum-encapsulated

electronics, make it particularly suitable for the mechanically

demanding environment, and it is rated for operation at

temperatures between -25ºC (-13ºF) and 70ºC (158ºF).

A narrow flange is attached to each end of the vehicle’s

hydraulic power-steering rack. The sensor is mounted

immediately below one end of the rack and detects the

position of the flange as it passes over the sensing face. The

sensing distance of 2mm eliminates any possibility of

accidental collision with the flange.

CUSTOMER VALUES

RELIABLE OPERATION DESPITE HIGH-OPERATING PRESSURES

EASE OF MOUNTING

REDUCED MAINTENANCE COSTS

INCREASED EFFICIENCY

PRODUCT ADVANTAGES

PRACTICALLY UNLIMITED NUMBER OF PRESSURE CYCLES

ACROSS THE PRESSURE RANGE – 10 TIMES GREATER

LONGEVITY THAN THE MARKET STANDARD

PEAK PRESSURE UP TO 1000 BAR (14500 PSI)

LONG OPERATING DISTANCES DESPITE PRESSURE RESISTANT

HOUSING

RESISTANCE TO DYNAMIC STRESSES

Manufacturers of mobile concrete pumping trucks trust

Contrinex’s High Pressure sensors to monitor the piston

position in the hydraulic drive cylinder.

These sensors provide exceptional reliability despite the

challenges of pressure cycles and high pressure peaks,

increasing longevity and efficiency and reducing maintenance

costs for these concrete pump.

An additional benefit is that these sensors are part of

Contrinex’s Extra Distance family and so combine long

operating distances despite the pressure resistant housing.

CUSTOMER APPLICATION

Concrete pumps use a double-piston pump and require two

feed cylinders that pump concrete at a working pressure of up

to 400 bar (5800 psi). These feed cylinders are driven by pairs

of hydraulic cylinder pairs which operate in push-pull

opposition. To achieve the maximum possible efficiency, the

timing of this push-pull operation must be precisely

coordinated. It is therefore essential to monitor the cylinder

limit position with sensors that are resistant to high-pressure.

The dynamic stresses on all components built into the

hydraulic system are very high, due to constantly changing

pressure cycles during pump operation.

Concrete pump failures are extremely costly because they can

cause construction problems and stoppages and risk

compromising the building being constructed.

If the breakdown is due to problems in the hydraulic system,

all the hydraulic oil must be drained to correct the fault. Then,

after refilling and before start-up, several time-consuming de-

aeration cycles must take place before the pump is fully fit for

service again. This prolongs the construction stoppage.

The customer’s requirements for longevity and resistance to

high peak pressures are essential to guarantee the smooth

operation of such systems.

CUSTOMER SOLUTION

Contrinex High-Pressure sensors (series 500P) withstand the

necessary pressure levels (peak pressure up to 1000 bar - 14500

psi) due to a patented process whereby a solid ceramic disk is

built into the stainless steel housing.

These sensors are fully resistant to dynamic stresses. A

patented technology ensures that all electronics, including the

ferrite core and coil, are located on the unpressurised side of

the housing. This results in an unusually long life under

pressure cycle stresses.

To monitor cylinder limit positions in the concrete pump, two

sensors are installed and connected to the control system. Due

to their longevity, which is ten times greater than the market

standard, maintenance costs are reduced to a minimum.

OFF-HIGHWAY AND RAIL APPLICATIONS SHARE A REQUIREMENT FOR ROBUST, HIGH-PERFORMANCE,

BUT LOW-COST SENSORS, WHICH MAKES CONTRINEX SENSORS POPULAR ACROSS THESE INDUSTRIES.

OFF-HIGHWAY & RAIL APPLICATIONS

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS, WE WILL WORK TO HELP YOU

SOLVE YOUR APPLICATIONS, IMPROVE MACHINE PERFORMANCE & RELIABILITY AND REDUCE COSTS

USING CONTRINEX’S EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

Rugged sensor construction ensures excellent resistance to

shock and vibration and a sensing distance of up to 10mm

eliminates any risk of accidental collision with moving parts.

These devices are corrosion-resistant and impervious to water

ingress, mud, ice and salt. Reliability has been excellent.

Contrinex inductive sensors deliver a cost-effective solution

that satisfies the customer’s requirements for a simple, fit-

and-forget system.

The ‘700’ Series ‘Extreme’ sensors are uniquely robust sensors

are typically demonstrated by Contrinex as being able to

repeatedly being used to hammer in nails. Even when their

front face is dented, the sensor continues to operate correctly.

Even under the harsh operating conditions of this application,

these sensors last several years and downtime attributable to

faulty sensors is minimal. Their long service life contributes to a

reduction in repair costs.

--

CUSTOMER VALUES

ELIMINATION OF HUMAN ERROR PREVENTS TRUCK BEING

DRIVEN IN AN UNSAFE CONDITION.

HIGHLY RELIABLE SENSING PERFORMANCE IN HIGHLY

DEMANDING CONDITIONS

CORROSION-RESISTANT SENSORS WITHSTAND WATER, ICE,

MUD AND SALT

HIGHLY COST-EFFECTIVE SOLUTION TO A POTENTIALLY

SERIOUS PROBLEM

PRODUCT ADVANTAGES

EXTREMELY ROBUST, IMPACT AND ABRASION RESISTANT IP68/

IP69K RATED HOUSING.

CORROSION-RESISTANT, V2A/ AISI 304 STAINLESS-STEEL,

FOOD-COMPATIBLE BODY.

LONG OPERATING DISTANCE OF 7MM IN A SMALL & SLIM

STAINLESS-STEEL 20X 32X 8MM HOUSING.

ROBUST, METAL-CASED INDUCTIVE PROXIMITY SENSORS

SUITABLE FOR EASY INTEGRATION

FACTOR 1 - CONSISTENT SENSING, IRRESPECTIVE OF WHETHER

THE TARGET IS STEEL OR ALUMINIUM.

RELIABLE, COMPACT VIBRATION-RESISTANT SENSORS

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

Hook loader trucks utilise a hydraulic system for loading and

unloading a demountable container. Once the container is

correctly positioned on the vehicle’s load bed, interlocks

engage with its base, securing it in position. Contrinex’s

rugged sensor systems detect full engagement of the

interlocks, ensuring the truck is safely loaded prior to driving

away. Therefore, the sensors must be mechanically robust and

able to withstand harsh outdoor conditions.

CUSTOMER APPLICATION

A specialist vehicle builder manufactures hydraulic hook-lift

systems for commercial trucks. A hook loader truck employs a

series of hydraulic rams to hook, lift and pull a demountable

container onto the vehicle’s load bed; a full container may

weigh up to 30 tons.

Hook loader trucks operate all year round, often in harsh

environments such as demolition and construction sites.

Hook-lift systems are typically semi-automated. The driver

positions the truck, engages the hook with the container and

initiates the lifting sequence. Once the container is pulled onto

the load bed, two interlock mechanisms, mounted on the

truck chassis, actuate and engage with the container body.

Once the interlocks are fully engaged, the container is secure

and the truck may be driven safely.

A highly reliable sensor system must detect the position of the

interlocks, ensuring that they are fully engaged before the

truck drives away. Sensors must be robust and must withstand

water, mud, dirt and ice. They may also be subject to

mechanical shock and vibration.

CUSTOMER SOLUTION

Rugged Full stainless-steel inductive sensors from the

Contrinex Extreme 700 Series are designed for demanding or

even exceptionally demanding environments, making them

ideal for this application. Highly reliable and IP68 / IP69K rated,

these embeddable units feature one-piece V2A (AISI 304)

stainless-steel construction with vacuum-encapsulated

electronics, making them well suited to the hostile operating

conditions.

During operation, a double-ended ram drives a pair of

interlock bolts into position. On either side of the truck, two

M18-diameter sensors are mounted in the wall of each bolt

housing; one detects the bolt as it reaches the fully engaged

position; the other detects it in the fully retracted position. A

second ram drives a rotating lock mechanism to engage with

the vehicle chassis; a further two sensors detect the position of

a cam on the locking shaft as it rotates.

Each sensor is configured with an industry-standard PNP

normally-open interface, and connection to the truck’s

hydraulic control system is via an integral M12 connector and

PUR-sheathed cable. This allows easy removal and

replacement during routine maintenance.

CUSTOMER VALUES

RELIABLE, EXCEPTIONAL RELIABILITY IN A HARSH OUTDOOR

ENVIRONMENT

AUTOMATIC OPERATION WITH OPTIMAL SPACE UTILISATION

ELIMINATION OF SWITCHING ERRORS DURING YEAR-ROUND

OPERATION

SIGNIFICANTLY REDUCED MAINTENANCE COSTS

PRODUCT ADVANTAGES

SENSING RANGE UP TO 12,000 MM

LONG SENSING RANGE IN SMALL SENSOR

EXCEPTIONAL RESISTANCE TO VIBRATION DURING OPERATION

When a tram reaches a road junction, wire-switches, installed

on the overhead conductor cables, control its direction of

travel, with switches in either the default “straight-through” or

“turnout” positions. As the tram passes a switch in the turnout

position, Contrinex photoelectric sensors mounted on the

overhead cables detect the presence of the pantograph

current collector so that the control system can then reset the

switch to the default position.

CUSTOMER APPLICATION

In urban tram transportation systems, wire-switches installed

on the overhead conductor cables at road junctions, control

the direction of travel for the trams. The switches default to the

straight-through position so that when a bus approaches a

turn, the driver uses a remote trigger to change the switch to

the turnout position. After the bus completes the turn, the

switch reverts to the straight-through position.

If a triggered switch reverts to the straight-through position

prematurely, the pantagraph current collector may become

disengaged, damaging the switch. Therefore tram operators

install safety systems to prevent premature switching.

Typically, these utilise timer circuits and a predetermined delay

or mechanical sensors that rely on physical contact with the

current collector, but neither system is reliable.

A Swiss manufacturer of trolley-bus control systems requires a

highly reliable, rugged sensor system that will detect the

presence of a current collector as it passes a switch. The

system must operate with minimal maintenance and

withstand the varied weather conditions of an outdoor

environment in Switzerland and therefore they selected

Contrinex sensors.

.

Customer Solution

Contrinex’s C23 through-beam photoelectric sensors offer

high-performance, small size and high-stability. A purpose-

designed metal bracket, mounted above the conductor cable,

holds the transmitter and receiver units in alignment on either

side of the cable. As the pantagraph current collector passes

between the two units it breaks the beam, triggering the

sensor and returning the switch to the straight-through

position.

The C23 photoelectric sensors are virtually impervious to the

harsh, outdoor environment and their small physically size (30

x 20 x 10mm) eliminates the risk of accidental damage arising

from a mechanical collision. The rugged construction and

vacuum-encapsulated electronics within the sensor minimise

the effects of vibration, ensuring a long service life.

Each unit is connected to the trolley-bus control systems via a

PVC-sheathed cable with a hermetically sealed entry. The

receiver has an industry-standard PNP interface. The one-

piece mounting bracket allows easy removal and replacement

of the complete assembly during routine maintenance.

Operational results have been excellent and the Contrinex

sensors have proved highly reliable, eliminating switching

errors and reducing maintenance costs significantly.

These rugged miniature sensors have a sensing range up to

30m, for Through-beam applications. They are very reliable

and cost-effective with the additional benefit of offering a

range of low-cost stainless-steel mounting and protection

brackets, making them ideal for a wide variety of applications.

CUSTOMER VALUES

SAFE, RELIABLE PERFORMANCE IN A DEMANDING OUTDOOR

ENVIRONMENT

NO LIKELIHOOD OF ACCIDENTAL DAMAGE ARISING IN

OPERATION

COST-EFFECTIVE SOLUTION, MAINTENANCE FREE

PRODUCT ADVANTAGES

CORROSION-RESISTANT STAINLESS-STEEL SENSOR RATED TO

IP68 AND IP69K

COST-EFFECTIVE HIGH-PERFORMANCE SENSOR WITH

EXCEPTIONAL RELIABILITY

BEST-IN-CLASS 20MM SENSING DISTANCE IN M30-DIAMETER

HOUSING

CUSTOMER SOLUTION

Contrinex inductive sensors are robust, reliable and offer

extended sensing distances; the Full Inox Extreme range is

ideal for this application. A one-piece M30-diameter stainless-

steel body and vacuum-encapsulated electronics make this

device particularly suitable for the mechanically demanding

environment, and the sensing distance of 20mm eliminates

any possibility of accidental collision in operation.

A metal bracket is mounted externally on the actuating

mechanism for the upper forks; the embeddable sensor is

mounted immediately adjacent to one of the forks and detects

the position of the actuating arm as it drives the fork into the

vertical position. The AISI 303/V2A stainless-steel housing and

sensing face are corrosion-resistant and impervious to water

ingress; the sensor is IP68- and IP69K-rated.

Configured with an industry-standard PNP normally-open

interface, the Contrinex M30 Extreme sensor connects to the

forklift’s lower-fork tilt-control systems via a flexible PUR-

sheathed cable. A sealed cable entry ensures fit-and-forget

capability during extended periods of operation in an outdoor

environment.

The Full Inox inductive sensor detects the vertical position of

the forklift’s upper forks effectively and repeatably, ensuring

safe, reliable operation of the unloading system. Contrinex

inductive sensors deliver a cost-effective solution that satisfies

the customer’s requirements for extreme robustness and

extended sensing distance

A container manufacturer uses a modified forklift, fitted with

two sets of forks, for unloading bulk cargo. The lower forks

support the container while the upper forks control the lid.

When unloading, the lid opens and the lower forks rotate,

tipping out the contents. A robust inductive sensor senses the

position of the lid, ensuring it opens fully before emptying.

CUSTOMER APPLICATION

Containers are often used when transporting bulk cargo,

including wood chip and biomass, by rail. A manufacturer of

bulk-cargo containers has developed an innovative unloading

system that uses only a modified forklift, eliminating the need

for specialist handling equipment.

The forklift has two pairs of lifting forks. The main forks,

mounted conventionally, support the weight of the container

as it is unloaded from a freight wagon; a second pair, mounted

vertically above the lower pair, opens and closes the lid of the

container. During opening, the upper forks lift the lid a short

distance before tilting it vertically, leaving the top of the

container completely unobstructed.

The lower forks then rotate about a horizontal axis, tilting the

container end-over-end and tipping the contents out. A robust

and reliable sensor system is required to detect the vertical

position of the lid before rotation begins. An extended sensing

distance is essential to eliminate the possibility of mechanical

damage.

CUSTOMER VALUES

RELIABLE, CONTINUOUS SPEED MONITORING IN HARSH

ENVIRONMENT

FIT-AND-FORGET SENSOR SOLUTION

EFFICIENT, COMPACT DESIGN POSSIBLE FOR MOBILE TURNING

MACHINE

NO SENSOR-RELATED DOWNTIME• NO REPAIR COSTS THANKS

TO EXCEPTIONALLY LONG SENSOR LIFE

PRODUCT ADVANTAGES

EXTREMELY ROBUST, IMPACT AND ABRASION RESISTANT IP68/

IP69K RATED HOUSING.

CORROSION-RESISTANT, V4A/ AISI 316L STAINLESS-STEEL,

FOOD-COMPATIBLE BODY.

LONG OPERATING DISTANCE OF 7MM IN A SMALL & SLIM

STAINLESS-STEEL 20X 32X 8MM HOUSING.

ROBUST, METAL-CASED INDUCTIVE PROXIMITY SENSORS

SUITABLE FOR EASY INTEGRATION

FACTOR 1 - CONSISTENT SENSING, IRRESPECTIVE OF WHETHER

THE TARGET IS STEEL OR ALUMINIUM.

RELIABLE, COMPACT VIBRATION-RESISTANT SENSORS

IO-LINK INTERFACE INCLUDED FOR FREE – IDEAL FOR

INDUSTRY 4

Agriculture is using increasingly complex automation in its

machinery and an example application is in composting

machines. Contrinex’s uniquely robust V4A/ 316L stainless-steel

sensors are relied upon for operating reliably in the

challenging environment of the inside of the machine’s drive

rotor. Withstanding dust, humidity and high temperatures, the

sensors enable the machine to provide the fast drying of

materials and optimal decomposition with reliable sanitisation

being ensured.

CUSTOMER APPLICATION

The efficient turning of organic materials – loosening, lifting

and aerating – is vitally important in industrial composting.

Special mobile equipment ensures fast drying of materials,

optimal decomposition and reliable sanitisation, processing

between 500 and 6800 cubic metres of earth per hour.

A manufacturer has introduced machine speed monitoring by

sensor. A sensor located in the rotor counts the passing teeth

of a rotating mechanical disk. From the number of teeth per

second, the controller then calculates the final speed.

Perfect sensor operation is required under these particularly

harsh conditions. In addition to permanent vibration and

shaking, the inductive sensor is also constantly exposed to

dust, moisture, and temperatures from 70 to 80°C (158 to

176°F). Since the location of the sensor in the rotor is hard to

access, the sensor must be very durable and low maintenance

to avoid time-consuming repairs.

CUSTOMER SOLUTION

Contrinex inductive sensors from the FULL INOX family,

Washdown range, are perfect for this application. Made from a

single piece of V4A stainless steel, including the sensing face,

they have no covers, caps or welding seams and are the most

robust inductive sensors on the market. They resist shock,

vibration, impact and abrasion and almost any exposure to

dirt, gases, or liquids such as oil, water and cleaning agents.

Functionally stable at temperatures from -25 to +85°C (-13 to

185°F), they are also insensitive to core breakage.

Thanks to the long operating distances of these sensors (three

times greater than the norm) a compact and efficient design

was possible using the M12 size. A long operating distance

allows the sensor to be mounted well away from the rotating

disk’s passing teeth. Setup is also straightforward, as

installation tolerances are less critical. A sensor version with

plug connector was chosen to allow speedy replacement if

necessary.

CUSTOMER VALUES

MAXIMUM VEHICLE UTILISATION WITH FEWER CONSTRAINTS

ON OPERATIONS

REAL-TIME INDICATION OF BEARING CONDITION AND WEAR

RATE

REDUCED MAINTENANCE COSTS WITH MINIMAL INCIDENCE OF

BREAKDOWNS

RELIABLE OPERATION IN A HIGHLY DEMANDING AND HARSH

ENVIRONMENT

PRODUCT ADVANTAGES

ANALOGUE DEVICE WITH EXTENDED 40MM SENSING RANGE

SMALL PHYSICAL SIZE (LESS THAN 50MM LENGTH)

EXCEPTIONAL ACCURACY AND RESOLUTION IN THE MICRON

RANGE

LONG LIFE, ESPECIALLY IN APPLICATIONS WITH TEMPERATURE

FLUCTUATIONS AND VIBRATIONS

Busy container seaports rely upon the ‘24/7’ operation of

specialist container-handling vehicles called Straddle Carriers

for loading, unloading and stacking containers. Often located

at ports, being beside the sea can mean that they have to work

in an aggressive and corrosive environment, requiring

frequent maintenance.

Because traditional, interval-based maintenance schedules are

not optimally efficient, condition-based intervention systems

which minimise the risk of breakdown, are popular. European

port operators therefore frequently rely upon Contrinex’s

rugged, analogue-output inductive sensors to monitor

components with a high risk of premature failure, maximising

vehicle utilisation and reducing maintenance costs.

CUSTOMER APPLICATION

A fleet of straddle carriers services a busy container port,

operating round the clock in a highly aggressive environment.

Frequent maintenance is necessary, but traditional, interval-

based maintenance schedules are not always optimal.

Condition-based intervention minimises the risk of

breakdowns, while imposing fewer constraints on day-to-day

operation; it also incurs cost only when necessary.

As a carrier moves over a container, a central spreader beam

lowers and locks onto the four corner fittings of the container.

Plain plastic bearings on the carrier legs guide the container as

it is raised; there is significant contamination from dirt and

other debris. Bearings wear rapidly in the all-weather

operating conditions.

A condition-monitoring system must measure bearing

thickness, repeatably and accurately, in realtime and with µm

resolution. Sensors must operate reliably in the harsh

environment with a minimum rating of IP67. Sensor length

must not exceed 70mm and a minimum sensing range of

30mm is mandatory.

CUSTOMER SOLUTION

Contrinex’s Analogue Inductive sensors, which feature ‘Extra

Distance’ technology are ideal for this demanding application.

These M30-diameter metal-bodied devices are IP67-rated and

provide an analogue voltage (0 to 10 volt) or current (4 to

20mA) output. The sensors are less than 50mm long with a

40mm sensing range, comfortably exceeding the specified

requirement.

A mild steel mounting plate, fixed immediately behind the

plastic bearing, locates each sensor with its sensing face in

contact with the rear surface of the bearing. As a container

passes over the front face of the bearing, the sensor measures

the distance to the metal container wall, and thus the bearing

thickness. Data is collected in real time with exceptional

accuracy and resolution in the micron range.

Data passes to on-board computers mounted on each carrier;

connection is via a flexible cable with an easily detachable M12

connector. At intervals, carriers transmit data wirelessly to a

central processor for detailed analysis.

The output gives a clear indication of the condition and wear

rate of each bearing, identifying any carrier requiring

maintenance. Consequently, the port operator has the means

to develop a genuine commercial advantage by eliminating

compromise from day-to-day operating processes

CUSTOMER VALUES

UNINTERRUPTED PRODUCTION AS POSITIONAL

IDENTIFICATION IS HIGHLY RELIABLE.

NO RISK OF SKEWING AS MOVEMENT OF THE MACHINE

STRUCTURE IS SYNCHRONISED.

ELIMINATION OF COLLISION DAMAGE BECAUSE OF SENSING

DISTANCE UP TO 45MM.

PRODUCT ADVANTAGES

PASSIVE RFID TRANSPONDER TAGS REQUIRE NO POWER

SOURCE AND MINIMAL MAINTENANCE.

RUGGED RFID TRANSPONDER TAGS WITH NYLON OR ALL-

METAL HOUSINGS SEALED TO IP67.

CONIDENT® TECHNOLOGY PROVIDES EXTENDED SENSING

RANGE ≤ 45MM.

READ/WRITE UNITS INTERFACE WITH A CHOICE OF INDUSTRY-

STANDARD CONTROL SYSTEMS OR IO-LINK

CUSTOMER SOLUTION

Contrinex high-frequency RFID read/write modules and

30mm-diameter RFID transponder tags are ideal for this

application. Rated up to IP67, the M30-diameter read/write

modules have PBTP sensing faces and V2A stainless-steel

housings, making them ideal for the demanding environment.

The ConIdent® passive transponders require no internal power

source and, with PBTP synthetic housings, have the same IP67

rating. The selected combination provides read/write distances

of up to 45mm (nearly 2 in), ideal for the specified operating

conditions. Tags are mounted at one-meter intervals along

each travel rail, each programmed with a unique identification

number.

As the machine passes a tag, the read/write module reads its

identification number at high speed; this is transmitted via a

PROFIBUS DP interface to the customer’s control system. A

simple look-up table confirms the location of the tag and thus

the position of the machine, allowing movement of both sides

of the structure to be synchronized without skewing.

Operation is independent of the direction of travel.

Contrinex ConIdent® RFID devices allow accurate and highly

reliable sensing of machine position and the long sensing

distance avoids any risk of collision damage. The customer

enjoys extended service life and robustness not available from

alternative position-detection systems, together with excellent

value for money

A manufacturer of bulk material-handling equipment uses

Contrinex Radio Frequency IDentification (RFID) technology to

sense the position of a large rail-mounted reclamation-

conveyor operating in a hot, dusty environment. A pair of read-

write modules, mounted on the machine structure,

interrogates a series of RFID tags, positioned at one-meter

intervals along each travel rail. The control system identifies

each tag individually and determines the exact position of the

machinery.

CUSTOMER APPLICATION

During surface-mining operations, large mobile reclamation

machines are used to recover bulk materials. On each

machine, a bucket-wheel excavator collects material and

deposits it onto a conveyor. As an area is cleared of material,

the machine moves along parallel steel travel rails to the next

area, allowing continuous operation without interruptions for

machine repositioning.

The distance between the travel rails is around 100 metres (300

ft) and travel speeds may reach 2m/sec (4.5 mph). If machine

movement along the two rails is not controlled accurately, the

two sides of the structure become misaligned, causing the

machine to skew. In this event, production is halted while the

machine is realigned; in the worst case, costly damage occurs.

A sensing system is required that detects the position of each

side of the machine structure accurately and reliably along the

entire length of the travel rails, allowing coordinated control of

the drive systems. Sensors must accommodate up to 10mm

lateral movement of the machine structure across either rail

and must withstand the hot, dusty environment of a desert

climate.

I

CUSTOMER VALUES

NON-CONTACT, ALL-ELECTRONIC DEVICE WITH SENSING

RANGE UP TO 500MM.

LARGE SENSING RANGE AVAILABLE IN A PHYSICALLY SMALL

SENSOR.• EXCEPTIONAL RESISTANCE TO EXTREME VIBRATION

DURING OPERATION.

OPTIMAL SPACE UTILISATION WITH LITTLE OR NO RELIANCE

ON OPERATOR INVOLVEMENT

PRODUCT ADVANTAGES

ELIMINATION OF CALIBRATION ERRORS DURING NORMAL

OPERATION

LARGE SENSING RANGE AVAILABLE IN PHYSICALLY SMALL

SENSOR

PROVIDES RELIABLE, REPEATABLE SENSING IN DEMANDING

OPERATING CONDITIONS

At busy container seaports, purpose-designed container-

handling vehicles called Straddle Carriers, operate around the

clock, loading, unloading and stacking containers. Space

utilisation is increasingly important and correctly identifying

the size of container picked for each lift is essential for

efficiency.

Contrinex photoelectric sensors have been fitted to the

Straddle Carriers to detect the container size and eliminate the

need for drivers to carry out identification checks, saving time

and avoiding errors.

CUSTOMER APPLICATION

A fleet of straddle carriers, purpose-designed container-

handling vehicles, services a busy French container port. As a

straddle carrier moves over a container, a central lifting beam

lowers and locks onto the corner castings of the container;

each lift comprises either a single 40-foot container or two 20-

foot containers.

Optimal utilisation of storage space is essential; correctly

identifying the size of container picked for each lift is vital.

Fitting carriers with sensors that detect the size and type of

containers at the time of lifting eliminate the need for drivers

to carry out identification checks, saving time and avoiding

errors.

The original mechanical sensors proved unreliable, losing

calibration when subjected to continuous vibration during

normal operation. Although the scheduled maintenance

interval for each vehicle is 1,000 hours, mechanical sensors

required recalibration at intervals of no more than two or three

days. A highly stable replacement sensor system was required.

CUSTOMER SOLUTION

Highly stable, non-contact, all-electronic units from the

Contrinex range of photoelectric sensors provide a reliable and

cost-effective alternative. The moulded-resin sensor casings,

fitted with coated-plastic sensing faces, are IP67 rated, making

them virtually impervious to the harsh, salt-laden environment

of a busy container port. Connection to the vehicle’s control

systems is via an integral M12 connector and PVC-sheathed

cable, allowing easy removal and replacement during routine

maintenance.

To confirm the size of the container, two pairs of diffuse

sensors with background suppression are mounted centrally

on each lifting beam. As the lifting beam descends, one sensor

from each pair detects the presence or absence of corner

castings at the central lifting points, while the other detects

the presence or absence of the gap between two 20-foot

containers. The combination of the two eliminates incorrect

identification in the unlikely event that the first sensor returns

a false-positive signal from a 40-foot container.

A physically small housing and long sensing distances

eliminate the risk of accidental damage arising from a

mechanical collision, while rugged industry-standard housings

and vacuum-encapsulated electronics minimise the effects of

vibration.

Operational results have been excellent; the new Contrinex

sensors have eliminated calibration errors and reduced

maintenance costs significantly.

A range of multi-purpose off-road tractors allows the driver to

choose between two-wheel or four-wheel steering. When

selecting two-wheel steering using the front wheels only, the

rear axle is locked in the straight-ahead position. Before the

axle is locked, rugged inductive sensors from Contrinex detect

the straight-ahead position accurately and reliably, ensuring

precise alignment of the tractor’s steering geometry.

CUSTOMER APPLICATION

Modern multi-purpose off-road utility vehicles are

exceptionally versatile, offering four-wheel drive and both front

and rear-wheel steering. Reliable operation all year round, on

all types of terrain and in all weather conditions, is essential as

typical tasks include bulk-load transportation and agricultural

engineering.

Extreme conditions often demand increased manoeuvrability;

for maximum control, the driver can engage four-wheel

steering when required. When reverting to the default two-

wheel steering configuration, the rear axle must be locked in

the straight-ahead position to prevent misalignment of the

rear wheels.

A rugged, reliable and accurate sensor system is required to

detect the straight-ahead position of the rear axle before it is

locked. The sensor must withstand significant mechanical

shock and vibration and must also be impervious to water

ingress. Additionally, it should accommodate the extremes of

temperature experienced during all-year-round operation.

CUSTOMER VALUES

RELIABLE, REPEATABLE SENSING PERFORMANCE IN

DEMANDING OPERATING CONDITIONS

FIT-AND-FORGET OPERATION WITH MINIMAL MAINTENANCE

TECHNICALLY ELEGANT, COST-EFFECTIVE SOLUTION

REQUIRING MINIMAL RE-ENGINEERING

PRODUCT ADVANTAGES

2MM SENSING DISTANCE ELIMINATES THE POSSIBILITY OF

ACCIDENTAL DAMAGE TO THE SENSOR

RUGGED, ROBUST STAINLESS-STEEL SENSOR WITH INTEGRAL

M8 CONNECTOR

AFFORDABLE HIGH-PERFORMANCE SENSOR WITH

EXCEPTIONAL RELIABILITY - FIT-AND-FORGET OPERATION

WITH MINIMAL MAINTENANCE

Configured with an industry-standard PNP normally-open

interface, the sensor features an integral M8 connector and

connects to the vehicle’s central controller via a flexible PVC-

sheathed cable. Adding the sensor requires minimal

modification to the vehicle’s control systems, and

maintenance is simple and speedy.

The sensor detects the straight-ahead position of the vehicle’s

rear axle repeatably and accurately, ensuring correct, reliable

engagement of two-wheel steering. Contrinex inductive

sensors provide the customer with a cost-effective fit-and-

forget solution to a challenging problem.

CUSTOMER SOLUTION

Inductive sensors from the Contrinex ‘Basic’ range are rugged,

reliable and accommodate the required extremes of

temperature; with an M8-sized sensor being ideal for this

application.

A V2A/AISI 303 stainless-steel body and vacuum-encapsulated

electronics, make it particularly suitable for the mechanically

demanding environment, and it is rated for operation at

temperatures between -25ºC (-13ºF) and 70ºC (158ºF).

A narrow flange is attached to each end of the vehicle’s

hydraulic power-steering rack. The sensor is mounted

immediately below one end of the rack and detects the

position of the flange as it passes over the sensing face. The

sensing distance of 2mm eliminates any possibility of

accidental collision with the flange.

CUSTOMER VALUES

RELIABLE OPERATION DESPITE HIGH-OPERATING PRESSURES

EASE OF MOUNTING

REDUCED MAINTENANCE COSTS

INCREASED EFFICIENCY

PRODUCT ADVANTAGES

PRACTICALLY UNLIMITED NUMBER OF PRESSURE CYCLES

ACROSS THE PRESSURE RANGE – 10 TIMES GREATER

LONGEVITY THAN THE MARKET STANDARD

PEAK PRESSURE UP TO 1000 BAR (14500 PSI)

LONG OPERATING DISTANCES DESPITE PRESSURE RESISTANT

HOUSING

RESISTANCE TO DYNAMIC STRESSES

Manufacturers of mobile concrete pumping trucks trust

Contrinex’s High Pressure sensors to monitor the piston

position in the hydraulic drive cylinder.

These sensors provide exceptional reliability despite the

challenges of pressure cycles and high pressure peaks,

increasing longevity and efficiency and reducing maintenance

costs for these concrete pump.

An additional benefit is that these sensors are part of

Contrinex’s Extra Distance family and so combine long

operating distances despite the pressure resistant housing.

CUSTOMER APPLICATION

Concrete pumps use a double-piston pump and require two

feed cylinders that pump concrete at a working pressure of up

to 400 bar (5800 psi). These feed cylinders are driven by pairs

of hydraulic cylinder pairs which operate in push-pull

opposition. To achieve the maximum possible efficiency, the

timing of this push-pull operation must be precisely

coordinated. It is therefore essential to monitor the cylinder

limit position with sensors that are resistant to high pressure.

The dynamic stresses on all components built into the

hydraulic system are very high, due to constantly changing

pressure cycles during pump operation.

Concrete pump failures are extremely costly because they can

cause construction problems and stoppages and risk

compromising the building being constructed.

If the breakdown is due to problems in the hydraulic system,

all the hydraulic oil must be drained to correct the fault. Then,

after refilling and before start-up, several time-consuming de-

aeration cycles must take place before the pump is fully fit for

service again. This prolongs the construction stoppage.

The customer’s requirements for longevity and resistance to

high peak pressures are essential to guarantee the smooth

operation of such systems.

CUSTOMER SOLUTION

Contrinex High-Pressure sensors (series 500P) withstand the

necessary pressure levels (peak pressure up to 1000 bar - 14500

psi) due to a patented process whereby a solid ceramic disk is

built into the stainless steel housing.

These sensors are fully resistant to dynamic stresses. A

patented technology ensures that all electronics, including the

ferrite core and coil, are located on the unpressurised side of

the housing. This results in an unusually long life under

pressure cycle stresses.

To monitor cylinder limit positions in the concrete pump, two

sensors are installed and connected to the control system. Due

to their longevity, which is ten times greater than the market

standard, maintenance costs are reduced to a minimum.

OFF-HIGHWAY & RAIL

APPLICATIONS

FOR MANUFACTURERS TO PLACE THEIR TRUST IN

TEST AND INSPECTION EQUIPMENT, THEY NEED TO

BE CONFIDENT IN THE SENSORS THEY USE -

CONTRINEX’S DURABILITY, RELIABILITY, AND HIGH-

PERFORMANCE THEREFORE MAKES THEM IDEAL.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS,

WE WILL HELP YOU SOLVE YOUR APPLICATIONS, IMPROVE MACHINE

PERFORMANCE & RELIABILITY AND REDUCE COSTS USING CONTRINEX’S

EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

Rugged sensor construction ensures excellent resistance to

shock and vibration and a sensing distance of up to 10mm

eliminates any risk of accidental collision with moving parts.

These devices are corrosion-resistant and impervious to water

ingress, mud, ice and salt. Reliability has been excellent.

Contrinex inductive sensors deliver a cost-effective solution

that satisfies the customer’s requirements for a simple, fit-

and-forget system.

The ‘700’ Series ‘Extreme’ sensors are uniquely robust sensors

are typically demonstrated by Contrinex as being able to

repeatedly being used to hammer in nails. Even when their

front face is dented, the sensor continues to operate correctly.

Even under the harsh operating conditions of this application,

these sensors last several years and downtime attributable to

faulty sensors is minimal. Their long service life contributes to a

reduction in repair costs.