(0121) 58 222 58 SALES@PLUSAUTOMATION.CO.UK

© 2021 - PLUS Automation Limited®

HELPING YOU #MAKE SENSE OF SENSORS

EXAMPLE APPLICATIONS

TO ILLUSTRATE THE WIDE-VARIETY OF APPLICATIONS SOLVED USING CONTRINEX SENSORS, WE HAVE POSTED A LARGE SELECTION OF EXAMPLE APPLICATIONS WHICH CAN BE SEEN BY CLICKING ON AN IMAGE. BELOW ARE A SELECTION OF SOME OF THESE APPLICATIONS:

CUSTOMER VALUES

COST-EFFECTIVE, ACTIVE SAFEGUARDING

IMPROVED WORKPLACE ERGONOMICS

INCREASED PRODUCTIVITY ARISING FROM UNIMPEDED

LOADING AND UNLOADING

INDUSTRY-STANDARD INTERFACE REQUIRES MINIMAL

MODIFICATION TO CONTROL SYSTEMS

PRODUCT ADVANTAGES

PERMANENT AUTOCONTROL NOT USUALLY FOUND ON TYPE 2

SAFETY DEVICES

IP65 AND IP67 PROTECTION

NON-CONTACT OPERATING PRINCIPLES

EXCELLENT SAFETY RATING TO EN/ISO 13849-1 CAT. 2 PL C

AND IEC 61508 SIL 1

AOPD (ACTIVE OPTOELECTRONIC PROTECTIVE DEVICE) WITH

ALUMINIUM HOUSING AND M12 CABLE CONNECTOR

CUSTOMER SOLUTION

The company’s risk assessment confirms that Type 2 AOPDs

(active optoelectronic protective devices) would ensure

appropriate operator protection. Designed for applications

where the risk has been evaluated as moderate, Safetinex IEC

61496 Type 2 light curtains from Contrinex are rated to EN/ISO

13849-1 Category 2, Performance Level PL c and IEC 61508

Safety Integrity Level SIL 1, making them ideal for the

application.

The heat-staking press is housed in an open-fronted enclosure

with clear impact-resistant walls. The light curtain has an

operating range of up to 12 metres and a resolution of 30 mm,

ideal for hand protection; it safeguards the open front area of

the press, allowing easy access when required. The protected

height is 795mm, ensuring safe operation without impeding

the operator during loading and unloading.

Manufactured with rugged extruded aluminium housings and

IP65 + IP67 protection, these units are well-suited to the

production environment and will withstand shocks and

vibrations.

Industry-standard PNP normally-open configuration allows

connection to the customer’s control system via an integral 5-

pin M12 cable connector. These units have an integrated

alignment LED and permanent autocontrol – a feature not

usually found on Type 2 safety devices.

The new sensors take up much less space than the

mechanical guards they replaced, improving workplace

ergonomics. Loading and unloading is no longer impeded,

increasing productivity while actively safeguarding operators.

Safetinex Type 2 light curtains provide a reliable and cost-

effective solution.

CUSTOMER VALUES

UNINTERRUPTED PRODUCTION AS BATCH IDENTIFICATION IS

HIGHLY RELIABLE

NO RESTRICTIONS ON USE OF CHEMICAL CLEANERS USING IP

67 OR IP69K-RATED TRANSPONDERS

LOW MAINTENANCE COSTS IN VIEW OF TRANSPONDERS’

EXTENDED SERVICE LIFE

LOW RISK OF MECHANICAL DAMAGE BECAUSE OF SENSING

DISTANCE UP TO 42MM

PRODUCT ADVANTAGES

PASSIVE TRANSPONDERS REQUIRE NO POWER SOURCE AND

MINIMAL MAINTENANCE

TRANSPONDER PERFORMANCE GUARANTEED FOR UP TO

100,000 ‘WRITE’ CYCLES

CONIDENT® TECHNOLOGY PROVIDES EXTENDED SENSING

RANGE ≤ 42MM

RUGGED TRANSPONDERS WITH NYLON OR ALL-METAL

HOUSINGS SEALED TO IP67 OR IP69K

READ/WRITE UNITS INTERFACE DIRECTLY WITH CUSTOMER

CONTROL SYSTEMS

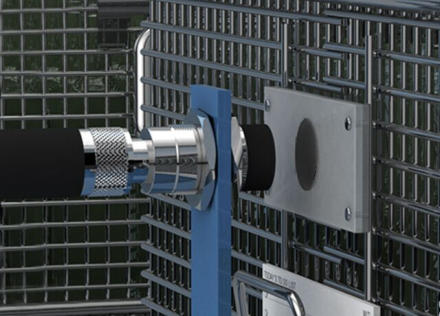

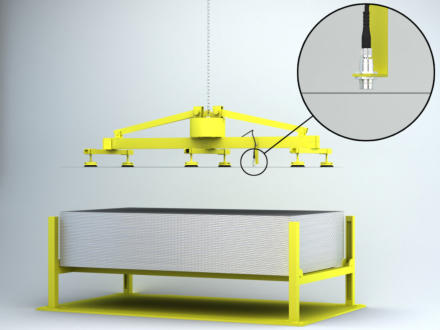

A manufacturer of industrial workpiece-carrier systems trusts

Contrinex Radio Frequency Identification (RFID) technology to

identify component baskets and initiate automated in-process

washing. A read-write module, mounted at the washing

station, interrogates the nylon-encased RFID tag on the

approaching carrier. The customer’s control system identifies

the carrier and initiates the correct washing cycle.

CUSTOMER APPLICATION

The manufacturer of automotive components needs to wash

components at several stages of the manufacturing process.

They wish to automate the production cycle, so that batches of

components, loaded in custom-designed, metal basket

carriers, can travel between process stations in an unordered

sequence. As each carrier approaches the washing station, the

customer’s control system automatically selects the correct

washing cycle for the batch.

The modular design of the metal basket carriers allows them

to transport more than one type of component. The basket

accepts a number of different inserts which are tailored for

specific components. The identification system must allow

component data to be stored temporarily and rewritten for

each batch, as a carrier is not always used for the same

component.

The production environment is harsh. RFID transponders and

read/write modules are exposed to hazards that include

mechanical shocks, hot water, corrosive chemicals and high-

pressure jetting. Identification systems must operate

continuously in this environment with ultra-high reliability.

Customer Solution

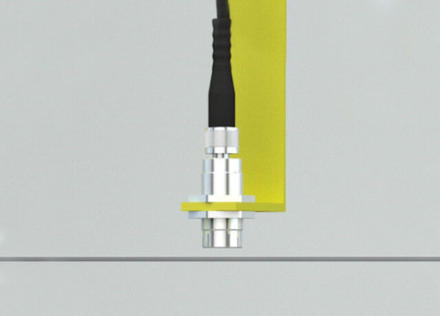

Contrinex RTP-0501-000 50mm-diameter RFID tags with nylon

housings are ideal for this application. The ConIdent® range

utilizes passive transponders which require no internal power

source, and a range of read/write modules rated up to IP67.

The RTP-0501 provides read/write distances of up to 42mm,

depending on the read/write module selected.

Each workpiece carrier has an integrated holder for an RFID

tag. Tags, which clip into the holder, are interchangeable and

are rated IP67 or IP69K. At the start of the production cycle,

the transponder is programmed with information including

component part number and batch ID.

Read/write modules on process stations read the tag on each

carrier. In an automotive manufacturing plant, different types

of component arrive in turn at the washing station, and the

information from the RFID tag is used to select the correct

washing cycle for each batch.

On completion of the complete production cycle, parts are

unloaded from the carrier. The customer’s PLC control system

checks the tag data against the expected value and then

overwrites the data on the tag in preparation for the next

batch.

Contrinex ConIdent® RFID devices allow unordered process

sequencing and provide excellent service life, reliability and

robustness lacking in alternative identification systems.

CUSTOMER VALUES

LESS HANDLING

ELIMINATE VISUAL INSPECTION

FEWER RETURNS

PROCESS VERIFICATION

PRODUCT ADVANTAGES

LONG OPERATING DISTANCE (3X STANDARD VALUE)

EXCELLENT SENSING STABILITY ON SMALL & THIN TARGETS

ROBUST, METAL-CASED INDUCTIVE PROXIMITY SENSORS

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

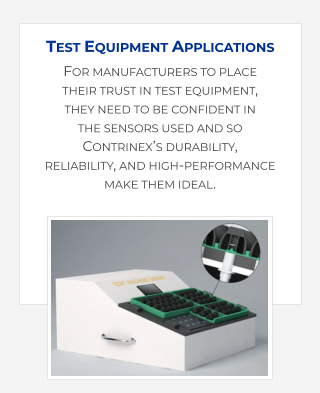

The automotive industry demands parts that are verified to be

100% correct and therefore a supplier of injection moulded

parts trusts Contrinex inductives from their Extra Distance 500

Series to check that threaded inserts have been correctly

mounted inside moulded plastic parts.

CUSTOMER APPLICATION

To enable the fast screw assembly required by automotive

plants it is common to embed threaded inserts, typically made

of brass, into plastic mouldings.

These nut-like elements are crucial to ensuring the correct

final assembly process of the car and so the supplier must be

able to ensure they are all present. It is not uncommon for

automotive companies to return several days’ worth of

production parts to a supplier and levy substantial fines if even

a minor error is found.

The design of the moulded plastic parts which are used in

automotive air filtration systems is problematic because it

prevents visual checking the presence of the inserts and so a

reliable test mechanism had to be found.

CUSTOMER SOLUTION

Contrinex DW-AS-513-M30-002 Extra Distance inductives are

used in a checking fixture to detect if any inserts are missing

or incorrectly mounted. The solution exploits the unique

sensing capabilities of the Condist® technology in these 500

Series sensors, utilising their longer sensing distances and

better stability to environmental influences. The long

operating distance and high sensing stability enable the

detection of small inserts through a thick layer of plastic.

The test fixture is designed to accept a finished moulding and

is equipped with sensors at each of the insert locations. Each

sensor can detect the presence of the corresponding metal

insert through moulded plastic and so confirm compliance

with the specifications. The sensor’s PNP Normally Open

output provides a logical GO – NO GO feed to a micro-

controller.

CONTRINEX SENSORS ARE RENOWNED FOR PERFORMANCE AND RELIABILITY

BY AUTOMOTIVE OEMS & THEIR SUPPLIERS AROUND THE WORLD..

CONTRINEX’S INNOVATIVE PRODUCTS ARE OFTEN DEVELOPED WITH AUTOMOTIVE MIND

- EXAMPLES INCLUDE THE UNIQUELY ROBUST 700 SERIES INDUCTIVES,

METAL-ENCASED & EMBEDDABLE RFID TRANSPONDERS, MACHINE

SAFETY SENSORS AND A WIDE PORTFOLIO OF PHOTOELECTRIC SENSORS.

- EXPERTS IN MINIATURISATION, CONTRINEX SENSORS ARE POPULAR FOR JIGS, GAUGES & ASSEMBLY.

AUTOMOTIVE MANUFACTURING,

SUPPLY & ASSEMBLY APPLICATIONS

CUSTOMER VALUES

UNINTERRUPTED PRODUCTION AS PART IDENTIFICATION IS

HIGHLY RELIABLE

NO RISK OF SYSTEM DEGRADATION AS TAGS ARE RESISTANT TO

HIGH TEMPERATURES

LOW MAINTENANCE COSTS IN VIEW OF TRANSPONDERS’

EXTENDED SERVICE LIFE

NO RISK OF PAINT CONTAMINATION OWING TO SILICONE-FREE

TAG CONSTRUCTION

PRODUCT ADVANTAGES

LCP-HOUSED TRANSPONDERS OPERATE AT TEMPERATURES

UP TO 250OC (482ºF)

CONIDENT® TECHNOLOGY IS HIGHLY TOLERANT OF SURFACE

CONTAMINATION

EXTENDED SENSING DISTANCES UP TO 56MM

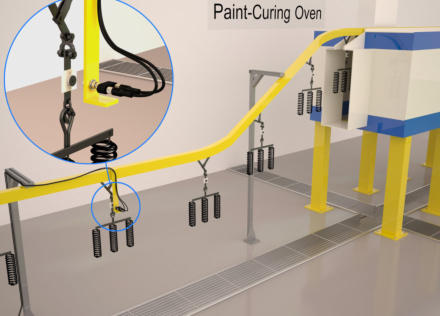

A manufacturer of automotive-suspension coil springs uses

Radio Frequency Identification (RFID) technology to identify

parts and monitor process status in an automated paint shop.

Parts travel on dedicated transport frames; each transport

frame, suspended from an overhead conveyor, is fitted with a

high-frequency, high-temperature RFID tag. During the paint-

curing cycle, temperatures may rise to 250°C (482°F) for more

than 30 minutes. Contrinex high-temperature transponders

operate reliably in this range.

CUSTOMER APPLICATION

Automotive suspension components require highly durable

surface finishes. A German manufacturer of suspension coil

springs operates an automated paint-processing plant that

degreases, spray-paints and heat-cures parts.

Springs travel through the plant on dedicated transport

frames. RFID tags, mounted on the frames, identify individual

parts. Throughout the process, read/write modules (RWMs),

compatible with ISO/IEC 15693, interrogate the tags and

update a centralized control system.

During the heat-curing process, the entire transport frame,

complete not only with parts but also with transponder, passes

through the curing oven. Curing temperatures reach 250°C

(482°F) for more than 30 minutes. Temperatures this high are

beyond the capabilities of many RFID tags. In the past,

complex mechanical arrangements were needed to shield

devices from elevated-temperature areas.

The customer requires RFID tags that not only withstand the

high-temperature environment but also offer complete

reliability and a service life of at least 2000 temperature cycles.

Compliance with ISO/IEC 15693 is mandatory to ensure

compatibility with existing RWMs.

Customer Solution

Contrinex high-temperature high-frequency (HF) RFID tags

are ideal for this application. These 50mm-diameter

ConIdent® passive transponders with liquid-crystal polymer

(LCP) housings are purpose-designed for operation at

temperatures up to 250°C (482°F). They require no internal

power source and are fully compliant with ISO/IEC 15693,

ensuring compatibility with the customer’s existing

equipment.

The tags, mounted directly onto the transport frames,

withstand repeated exposure to elevated temperatures and

easily achieve the required service life. ConIdent® technology

is also highly tolerant of surface contamination, and the tags

ensure continuous error-free operation in spite of unavoidable

soiling with paint overspray. These Contrinex RFID tags also

boast silicone-free construction – an essential anti-

contamination requirement for paint-shop applications.

Contrinex transponders not only withstand the environment,

they accommodate the variability of a transport frame’s travel

path. Since the frame is not constrained from moving about

its vertical axis, the exact path of the tag may vary from frame

to frame – often by several millimetres. The system allows for

this movement and produces reliable results that are

independent of the exact tag position.

Contrinex RFID tags provide accurate and highly reliable part

identification in a demanding high-temperature environment.

The customer enjoys extended service life and robustness not

available from alternative transponders, together with

excellent value for money.

CUSTOMER VALUES

PROVEN TECHNOLOGY TO ENSURE HIGHLY RELIABLE FIT-&-

FORGET POKA YOKE QUALITY CONTROL WITH NO MANUAL

INTERVENTION

UNOBTRUSIVE SYSTEM THAT DOES NOT IMPACT UPON THE

WELDING STATION CYCYLE TIMES

FAST & EASY SWAP OUT IN CASE OF DAMAGE TO THE SENSOR

PRODUCT ADVANTAGES

COMPACT & ROBUST, ALUMINIUM EXTRUDED HOUSING - 40 X

20.5MM)

DIVERSE PORTFOLIO OFFERS EXCEPTIONAL RANGE OF SIZES -

100 TO 2,000MM HEIGHT AND 0.9 TO 25MM RESOLUTION

FAST & EASY INTEGRATION WITH M12 CONNECTORS

LOW COST, HIGH PERFORMANCE AND LONG SENSING RANGE

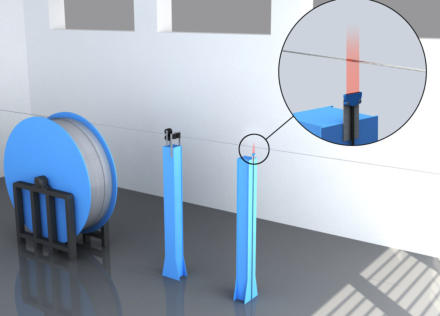

During manufacture of mechanical assemblies for automotive

production, an operator uses a manually operated machine to

weld metal parts together. After welding, the operator drops

the assembly in a transport bin ready for dispatch. As each

assembly is placed in the bin, an infra-red light detection grid

sensor detects its presence and confirms that the welding

cycle has been completed correctly

CUSTOMER APPLICATION

In an automotive 1st tier supplier manufacturing plant, an

operator loads small parts by hand onto a resistance-welding

machine and initiates the PLC-controlled welding cycle. After

welding, the operator drops the completed assembly into a

metal bin used to transport parts directly to the customer.

From time to time, unwelded parts are placed in the bin,

resulting in rejection of entire batches of assemblies by the

customer. Manual inspection of each assembly is impractical; a

sensor system must detect the presence of each item as it is

dropped into the bin and check that the corresponding

welding cycle has been completed.

The sensing system must not increase the process cycle-time

and must detect parts as they are dropped into the open bin,

which is approximately 120cm (4ft) long and 90cm (3ft) wide.

Parts are around 15cm (6in) long and a sensor with a rapid

response time is necessary to detect fast-moving items.

Customer Solution

The Contrinex DGI range of infrared light detection grids is

well-suited for this application. Comprising separate sender-

and receiver-units and constructed with rugged one-piece

aluminium-profile housings, these versatile sensor systems are

ideal for the busy production environment.

With response times from 0.8 to 4.8 milliseconds which are

faster than safety light-curtains and a choice of resolutions

from 0.9 to 25mm dependent upon the size of the light grid,

the DGI light detection grids range exceed the demanding

customer specification for rapid response and reliable

detection of the small parts.

The 8m range between sender and receiver and their compact

design enables easy mounting at each end of the transport

bin without impeding the operator or increasing the process

cycle time.

The DGI light detection grid sender only requires a power

supply connection and the receiver features two Push-Pull

(PNP + NPN), Light-ON+ Dark-ON, 4-pin M12 outputs,

simplifying installation.

The system detects the presence of any item passing through

the light curtain and immediately interrogates the PLC to

confirm that a welding cycle has been completed since

detection of the preceding item. If no welding cycle is

registered, the system interrupts the process and sounds an

alarm, alerting the operator.

CUSTOMER VALUES

RAPID, RELIABLE DETECTION OF A SMALL, FAST-MOVING

TARGET WITH AN ERRATIC PATH

ELIMINATION OF DOWNTIME ARISING FROM BROKEN CABLES

HIGHLY COST-EFFECTIVE SOLUTION TO A POTENTIALLY COSTLY

PROBLEM

PRODUCT ADVANTAGES

SYSTEM SWITCHING FREQUENCY OF UP TO 4000 HZ

EXCEPTIONALLY RELIABLE DETECTION ACROSS A 90MM X

20MM ENVELOPE

DIFFUSE DETECTOR WITH SIMPLE SET-UP AND TEACH-IN

FUNCTION

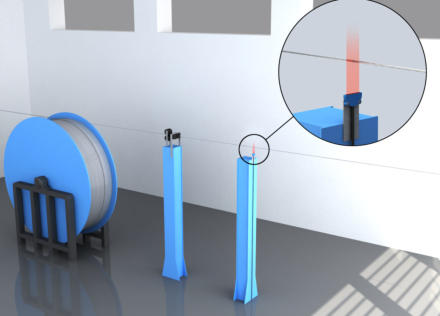

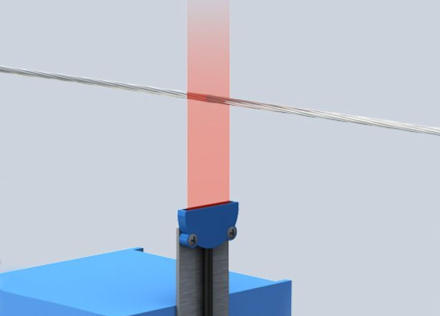

During manufacture of automotive parking-brake cable,

multiple strands of steel wire are twisted together, forming a

single cable. After twisting, cable passes to the next process in

an unsupported, continuous length. Occasionally, the cable

breaks, compromising safety and damaging equipment.

Although the cable’s exact path is unpredictable, a multi-

beam fibre-optic sensor detects its presence, interrupting the

process if it breaks.

CUSTOMER APPLICATION

During production of automotive parking-brake cable in a

Portuguese factory, strands of steel wire are twisted together,

forming a single cable with a nominal diameter of 3mm (0.1in).

The process operates continuously, and twisted cable passes

between successive work-stations in an unbroken length.

Between operations, the cable is largely unsupported,

assuming the form of a suspended catenary.

Occasionally, a manufacturing defect causes the cable to

break. In this event, safety is compromised and, unless

processing is halted, machine breakdowns occur. A sensor

system must detect the presence of the cable as it passes

from one operation to the next, interrupting the process if it

breaks.

Because the cable is unsupported, its path is unpredictable

and its exact position at any time, particularly in the vertical

plane, is unknown. The sensor system must detect the

presence of the cable reliably at any point within an envelope

90mm (3.5in) high and 20mm (0.75in) wide.

Customer Solution

A Contrinex photoelectric sensor system, comprising a DIN-

rail-mounted fibre-optic amplifier coupled with a multi-beam

diffuse sensing head, provides an optimal solution for this

application. With maximum switching frequencies of up to

4000 Hz and sensing distances of up to 150mm (6in), multi-

beam fibre-optic sensors are ideal for detecting fast-moving

targets. The PBTP construction of the sensing head ensures

excellent mechanical protection in the production

environment.

The 28mm-wide sensing face of the multi-beam sensor

detects targets across its entire width, providing a detection

envelope that comfortably accommodates the customer’s

90mm x 20mm requirement. Initial set-up is accomplished by

means of a manual teach-in function and integral signal-

strength LCD, following which the system operates without

manual intervention.

A 2m-long fibre cable allows remote mounting of the fibre-

optic amplifier; connection to the customer’s control system is

via an industry-standard PNP interface and an integral M8

cable connector, allowing easy removal and replacement

when necessary.

The system tolerates high ambient-light conditions and

detection of a broken cable is both highly reliable and

immediate. If the cable breaks, the system interrupts the

process and sounds an alarm, alerting the operator. Downtime

arising from broken cables has been eliminated since the

system has been operational.

CUSTOMER VALUES

RELIABLE DOUBLE-SHEET DETECTION ELIMINATES TOOL

DAMAGE AND DOWNTIME

COMPACT, ROBUST SENSOR ENSURES CONVENIENT,

UNOBTRUSIVE OPERATION

INCREASED FLEXIBILITY AS A SINGLE SENSOR DETECTS

SEVERAL DIFFERENT MATERIALS (EG CARBON STEEL,

STAINLESS STEEL & ALUMINIUM)

REDUCED COMPLEXITY AS SENSOR CONNECTS DIRECTLY TO

THE CUSTOMER’S CONTROL SYSTEM

PRODUCT ADVANTAGES

SENSOR SPECIALLY DEVELOPED FOR DETECTING MULTIPLE

OVERLAPPING METAL SHEETS

CONDET® TECHNOLOGY MAKES PERFORMANCE

INDEPENDENT OF TARGET MATERIAL

RUGGED INDUCTIVE SENSOR WITH ONE-PIECE STAINLESS

STEEL CONSTRUCTION

EXTENDED SENSING DISTANCE AVOIDS RISK OF MECHANICAL

DAMAGE

Contrinex’s innovative sensors provide affordable detection of

overlapping metal sheets. They can protect a press-line by

checking that two metal blanks are not presented to the

forming press, or alternatively ensure two pieces of metal are

present for example in an automotive welding assembly –

Sometimes two’s too many, but sometimes you just need two.

CUSTOMER APPLICATION

A producer of deep-drawn metal parts for the automotive

industry uses Contrinex’s double-sheet sensing to prevent

costly tool damage and downtime.

Deep drawing and other metal-forming techniques are widely

used in the automotive industry, which requires expensive

press tools to produce complex profiles from sheet metal

blanks. During high-volume production, an automated feeder

loads sheets of steel or aluminium to the press.

The metal sheets are lightly lubricated to reduce friction

during deep drawing, but the thin film of oil can cause two

sheets to stick together in the feeder. If the press operates with

such double sheets loaded, the forming tool will be damaged,

resulting in downtime and large repair costs. Therefore

sensing systems are used to check the material before it is

loaded.

Previously, the customer had trailed alternative sensor

technologies. All were excessively cumbersome and difficult to

set up, and most were unable to detect double sheets reliably.

Customer Solution

Contrinex offers a rugged, compact stainless-steel -bodied

sensor for the loading station, which checks each metal sheet

as it is presented by the feeder. If it detects a double sheet, the

material is rejected and the operating cycle inhibited, which

reduces expensive damage to tooling and improves OEE.

The sensor enables discrimination between single and double

metal sheets of a defined thickness of steel or aluminium in

the size range of 0.8 – 1.2mm thick.

A specialist version of Contrinex’s uniquely robust ‘700 Series’

family of inductive sensors, they share the benefits of being

both impact and abrasion resilient and having a case

machined from a single-piece of stainless-steel – These are the

sensors whose robustness is demonstrated by using them to

hammer in nails.

The reliability of their performance and robustness enable you

to minimise downtime and improve the OEE of Press-lines or

verify assembly operations.

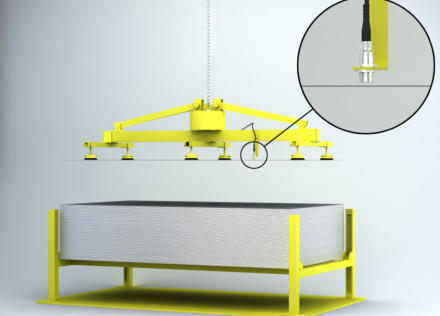

During semi-automated heat staking of assemblies

manufacturers use light curtains to preserve operator safety

without compromising production throughput. The active

optoelectronic protective device (AOPD), mounted directly in

front of each bench-mounted heat-press, prevents the press-

head from descending if it detects any intrusion in the

working area, halting the operating cycle immediately.

CUSTOMER APPLICATION

Heat-staking is a popular process for fastening metal parts to

plastic moldings, and is commonly used by manufacturers

during the production of sub-assemblies. At each station, an

operator loads a molding and one or more metal parts into a

slide-mounted assembly fixture. Once the components are

correctly inserted, the operator pushes the slide into position

beneath the press-head, triggering the automated heat-

staking cycle.

The heated press-head, which may reach temperatures in

excess of 350oC (660oF), descends toward the pre-positioned

components. It applies heat and pressure to specific areas of

the molding, causing a controlled thermal deformation that

creates a permanent joint between the metal parts and the

molding. Following a pre-determined dwell period, the head

returns to the raised position, ending the cycle; the operator

withdraws the slide and removes the assembly from the

fixture.

Existing mechanical safety barriers are cumbersome and

inconvenient; throughput is constrained as a result of the time

taken to open and close the guards during each cycle. The

company requires an alternative safety guard that provides

effective hand protection while allowing unobstructed loading

and unloading. It must be simple, space-saving and operate

reliably in the production environment.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS, WE WILL WORK TO HELP YOU

SOLVE YOUR APPLICATIONS, IMPROVE MACHINE PERFORMANCE & RELIABILITY AND REDUCE COSTS

USING CONTRINEX’S EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

CUSTOMER VALUES

COST-EFFECTIVE, ACTIVE SAFEGUARDING

IMPROVED WORKPLACE ERGONOMICS

INCREASED PRODUCTIVITY ARISING FROM UNIMPEDED

LOADING AND UNLOADING

INDUSTRY-STANDARD INTERFACE REQUIRES MINIMAL

MODIFICATION TO CONTROL SYSTEMS

PRODUCT ADVANTAGES

PERMANENT AUTOCONTROL NOT USUALLY FOUND ON TYPE 2

SAFETY DEVICES

IP65 AND IP67 PROTECTION

NON-CONTACT OPERATING PRINCIPLES

EXCELLENT SAFETY RATING TO EN/ISO 13849-1 CAT. 2 PL C

AND IEC 61508 SIL 1

AOPD (ACTIVE OPTOELECTRONIC PROTECTIVE DEVICE) WITH

ALUMINIUM HOUSING AND M12 CABLE CONNECTOR

CUSTOMER SOLUTION

The company’s risk assessment confirms that Type 2 AOPDs

(active optoelectronic protective devices) would ensure

appropriate operator protection. Designed for applications

where the risk has been evaluated as moderate, Safetinex IEC

61496 Type 2 light curtains from Contrinex are rated to EN/ISO

13849-1 Category 2, Performance Level PL c and IEC 61508

Safety Integrity Level SIL 1, making them ideal for the

application.

The heat-staking press is housed in an open-fronted enclosure

with clear impact-resistant walls. The light curtain has an

operating range of up to 12 metres and a resolution of 30 mm,

ideal for hand protection; it safeguards the open front area of

the press, allowing easy access when required. The protected

height is 795mm, ensuring safe operation without impeding

the operator during loading and unloading.

Manufactured with rugged extruded aluminium housings and

IP65 + IP67 protection, these units are well-suited to the

production environment and will withstand shocks and

vibrations.

Industry-standard PNP normally-open configuration allows

connection to the customer’s control system via an integral 5-

pin M12 cable connector. These units have an integrated

alignment LED and permanent autocontrol – a feature not

usually found on Type 2 safety devices.

The new sensors take up much less space than the

mechanical guards they replaced, improving workplace

ergonomics. Loading and unloading is no longer impeded,

increasing productivity while actively safeguarding operators.

Safetinex Type 2 light curtains provide a reliable and cost-

effective solution.

CUSTOMER VALUES

UNINTERRUPTED PRODUCTION AS BATCH IDENTIFICATION IS

HIGHLY RELIABLE

NO RESTRICTIONS ON USE OF CHEMICAL CLEANERS USING IP

67 OR IP69K-RATED TRANSPONDERS

LOW MAINTENANCE COSTS IN VIEW OF TRANSPONDERS’

EXTENDED SERVICE LIFE

LOW RISK OF MECHANICAL DAMAGE BECAUSE OF SENSING

DISTANCE UP TO 42MM

PRODUCT ADVANTAGES

PASSIVE TRANSPONDERS REQUIRE NO POWER SOURCE AND

MINIMAL MAINTENANCE

TRANSPONDER PERFORMANCE GUARANTEED FOR UP TO

100,000 ‘WRITE’ CYCLES

CONIDENT® TECHNOLOGY PROVIDES EXTENDED SENSING

RANGE ≤ 42MM

RUGGED TRANSPONDERS WITH NYLON OR ALL-METAL

HOUSINGS SEALED TO IP67 OR IP69K

READ/WRITE UNITS INTERFACE DIRECTLY WITH CUSTOMER

CONTROL SYSTEMS

A manufacturer of industrial workpiece-carrier systems trusts

Contrinex Radio Frequency Identification (RFID) technology to

identify component baskets and initiate automated in-process

washing. A read-write module, mounted at the washing

station, interrogates the nylon-encased RFID tag on the

approaching carrier. The customer’s control system identifies

the carrier and initiates the correct washing cycle.

CUSTOMER APPLICATION

The manufacturer of automotive components needs to wash

components at several stages of the manufacturing process.

They wish to automate the production cycle, so that batches of

components, loaded in custom-designed, metal basket

carriers, can travel between process stations in an unordered

sequence. As each carrier approaches the washing station, the

customer’s control system automatically selects the correct

washing cycle for the batch.

The modular design of the metal basket carriers allows them

to transport more than one type of component. The basket

accepts a number of different inserts which are tailored for

specific components. The identification system must allow

component data to be stored temporarily and rewritten for

each batch, as a carrier is not always used for the same

component.

The production environment is harsh. RFID transponders and

read/write modules are exposed to hazards that include

mechanical shocks, hot water, corrosive chemicals and high-

pressure jetting. Identification systems must operate

continuously in this environment with ultra-high reliability.

Customer Solution

Contrinex RTP-0501-000 50mm-diameter RFID tags with nylon

housings are ideal for this application. The ConIdent® range

utilizes passive transponders which require no internal power

source, and a range of read/write modules rated up to IP67.

The RTP-0501 provides read/write distances of up to 42mm,

depending on the read/write module selected.

Each workpiece carrier has an integrated holder for an RFID

tag. Tags, which clip into the holder, are interchangeable and

are rated IP67 or IP69K. At the start of the production cycle,

the transponder is programmed with information including

component part number and batch ID.

Read/write modules on process stations read the tag on each

carrier. In an automotive manufacturing plant, different types

of component arrive in turn at the washing station, and the

information from the RFID tag is used to select the correct

washing cycle for each batch.

On completion of the complete production cycle, parts are

unloaded from the carrier. The customer’s PLC control system

checks the tag data against the expected value and then

overwrites the data on the tag in preparation for the next

batch.

Contrinex ConIdent® RFID devices allow unordered process

sequencing and provide excellent service life, reliability and

robustness lacking in alternative identification systems.

CUSTOMER VALUES

LESS HANDLING

ELIMINATE VISUAL INSPECTION

FEWER RETURNS

PROCESS VERIFICATION

PRODUCT ADVANTAGES

LONG OPERATING DISTANCE (3X STANDARD VALUE)

EXCELLENT SENSING STABILITY ON SMALL & THIN TARGETS

ROBUST, METAL-CASED INDUCTIVE PROXIMITY SENSORS

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

The automotive industry demands parts that are verified to be

100% correct and therefore a supplier of injection moulded

parts trusts Contrinex inductives from their Extra Distance 500

Series to check that threaded inserts have been correctly

mounted inside moulded plastic parts.

CUSTOMER APPLICATION

To enable the fast screw assembly required by automotive

plants it is common to embed threaded inserts, typically made

of brass, into plastic mouldings.

These nut-like elements are crucial to ensuring the correct

final assembly process of the car and so the supplier must be

able to ensure they are all present. It is not uncommon for

automotive companies to return several days’ worth of

production parts to a supplier and levy substantial fines if even

a minor error is found.

The design of the moulded plastic parts which are used in

automotive air filtration systems is problematic because it

prevents visual checking the presence of the inserts and so a

reliable test mechanism had to be found.

CUSTOMER SOLUTION

Contrinex DW-AS-513-M30-002 Extra Distance inductives are

used in a checking fixture to detect if any inserts are missing

or incorrectly mounted. The solution exploits the unique

sensing capabilities of the Condist® technology in these 500

Series sensors, utilising their longer sensing distances and

better stability to environmental influences. The long

operating distance and high sensing stability enable the

detection of small inserts through a thick layer of plastic.

The test fixture is designed to accept a finished moulding and

is equipped with sensors at each of the insert locations. Each

sensor can detect the presence of the corresponding metal

insert through moulded plastic and so confirm compliance

with the specifications. The sensor’s PNP Normally Open

output provides a logical GO – NO GO feed to a micro-

controller.

AUTOMOTIVE

MANUFACTURING, SUPPLY &

ASSEMBLY APPLICATIONS

RENOWNED FOR PERFORMANCE AND

RELIABILITY BY AUTOMOTIVE OEMS AND

THEIR SUPPLY BASE, CONTRINEX SENSORS

ARE TRUSTED AROUND THE WORLD.

CONTRINEX’S INNOVATIVE PRODUCTS ARE OFTEN

DEVELOPED WITH AUTOMOTIVE MIND

- EXAMPLES INCLUDE THE UNIQUELY ROBUST 700

SERIES INDUCTIVES, METAL-ENCASED &

EMBEDDABLE RFID TRANSPONDERS,

MACHINE SAFETY SENSORS AND A WIDE

PORTFOLIO OF PHOTOELECTRIC SENSORS.

- EXPERTS IN MINIATURISATION, CONTRINEX

SENSORS ARE POPULAR FOR JIGS & ASSEMBLY.

A manufacturer of automotive-suspension coil springs uses

Radio Frequency Identification (RFID) technology to identify

parts and monitor process status in an automated paint shop.

Parts travel on dedicated transport frames; each transport

frame, suspended from an overhead conveyor, is fitted with a

high-frequency, high-temperature RFID tag. During the paint-

curing cycle, temperatures may rise to 250°C (482°F) for more

than 30 minutes. Contrinex high-temperature transponders

operate reliably in this range.

CUSTOMER APPLICATION

Automotive suspension components require highly durable

surface finishes. A German manufacturer of suspension coil

springs operates an automated paint-processing plant that

degreases, spray-paints and heat-cures parts.

Springs travel through the plant on dedicated transport

frames. RFID tags, mounted on the frames, identify individual

parts. Throughout the process, read/write modules (RWMs),

compatible with ISO/IEC 15693, interrogate the tags and

update a centralized control system.

During the heat-curing process, the entire transport frame,

complete not only with parts but also with transponder, passes

through the curing oven. Curing temperatures reach 250°C

(482°F) for more than 30 minutes. Temperatures this high are

beyond the capabilities of many RFID tags. In the past,

complex mechanical arrangements were needed to shield

devices from elevated-temperature areas.

The customer requires RFID tags that not only withstand the

high-temperature environment but also offer complete

reliability and a service life of at least 2000 temperature cycles.

Compliance with ISO/IEC 15693 is mandatory to ensure

compatibility with existing RWMs.

Customer Solution

Stack-feeders deliver base plates, electrical printed circuit

boards and other planar components to the assembly lines. In

Contrinex high-temperature high-frequency (HF) RFID tags

are ideal for this application. These 50mm-diameter

ConIdent® passive transponders with liquid-crystal polymer

(LCP) housings are purpose-designed for operation at

temperatures up to 250°C (482°F). They require no internal

power source and are fully compliant with ISO/IEC 15693,

ensuring compatibility with the customer’s existing

equipment.

The tags, mounted directly onto the transport frames,

withstand repeated exposure to elevated temperatures and

easily achieve the required service life. ConIdent® technology

is also highly tolerant of surface contamination, and the tags

ensure continuous error-free operation in spite of unavoidable

soiling with paint overspray. These Contrinex RFID tags also

boast silicone-free construction – an essential anti-

contamination requirement for paint-shop applications.

Contrinex transponders not only withstand the environment,

they accommodate the variability of a transport frame’s travel

path. Since the frame is not constrained from moving about

its vertical axis, the exact path of the tag may vary from frame

to frame – often by several millimetres. The system allows for

this movement and produces reliable results that are

independent of the exact tag position.

Contrinex RFID tags provide accurate and highly reliable part

identification in a demanding high-temperature environment.

The customer enjoys extended service life and robustness not

available from alternative transponders, together with

excellent value for money.

CUSTOMER VALUES

RAPID, RELIABLE DETECTION OF A SMALL, FAST-MOVING

TARGET WITH AN ERRATIC PATH

ELIMINATION OF DOWNTIME ARISING FROM BROKEN CABLES

HIGHLY COST-EFFECTIVE SOLUTION TO A POTENTIALLY COSTLY

PROBLEM

PRODUCT ADVANTAGES

SYSTEM SWITCHING FREQUENCY OF UP TO 4000 HZ

EXCEPTIONALLY RELIABLE DETECTION ACROSS A 90MM X

20MM ENVELOPE

DIFFUSE DETECTOR WITH SIMPLE SET-UP AND TEACH-IN

FUNCTION

Customer Solution

The Contrinex DGI range of infrared light detection grids is

well-suited for this application. Comprising separate sender-

and receiver-units and constructed with rugged one-piece

aluminium-profile housings, these versatile sensor systems are

ideal for the busy production environment.

With response times from 0.8 to 4.8 milliseconds which are

faster than safety light-curtains and a choice of resolutions

from 0.9 to 25mm dependent upon the size of the light grid,

the DGI light detection grids range exceed the demanding

customer specification for rapid response and reliable

detection of the small parts.

The 8m range between sender and receiver and their compact

design enables easy mounting at each end of the transport

bin without impeding the operator or increasing the process

cycle time.

The DGI light detection grid sender only requires a power

supply connection and the receiver features two Push-Pull

(PNP + NPN), Light-ON+ Dark-ON, 4-pin M12 outputs,

simplifying installation.

The system detects the presence of any item passing through

the light curtain and immediately interrogates the PLC to

confirm that a welding cycle has been completed since

detection of the preceding item. If no welding cycle is

registered, the system interrupts the process and sounds an

alarm, alerting the operator.

CUSTOMER VALUES

UNINTERRUPTED PRODUCTION AS PART IDENTIFICATION IS

HIGHLY RELIABLE

NO RISK OF SYSTEM DEGRADATION AS TAGS ARE RESISTANT TO

HIGH TEMPERATURES

LOW MAINTENANCE COSTS IN VIEW OF TRANSPONDERS’

EXTENDED SERVICE LIFE

NO RISK OF PAINT CONTAMINATION OWING TO SILICONE-FREE

TAG CONSTRUCTION

PRODUCT ADVANTAGES

LCP-HOUSED TRANSPONDERS OPERATE AT TEMPERATURES

UP TO 250OC (482ºF)

CONIDENT® TECHNOLOGY IS HIGHLY TOLERANT OF SURFACE

CONTAMINATION

EXTENDED SENSING DISTANCES UP TO 56MM

CUSTOMER VALUES

PROVEN TECHNOLOGY TO ENSURE HIGHLY RELIABLE FIT-&-

FORGET POKA YOKE QUALITY CONTROL WITH NO MANUAL

INTERVENTION

UNOBTRUSIVE SYSTEM THAT DOES NOT IMPACT UPON THE

WELDING STATION CYCYLE TIMES

FAST & EASY SWAP OUT IN CASE OF DAMAGE TO THE SENSOR

PRODUCT ADVANTAGES

COMPACT & ROBUST, ALUMINIUM EXTRUDED HOUSING - 40 X

20.5MM)

DIVERSE PORTFOLIO OFFERS EXCEPTIONAL RANGE OF SIZES -

100 TO 2,000MM HEIGHT AND 0.9 TO 25MM RESOLUTION

FAST & EASY INTEGRATION WITH M12 CONNECTORS

LOW COST, HIGH PERFORMANCE AND LONG SENSING RANGE

During manufacture of mechanical assemblies for automotive

production, an operator uses a manually operated machine to

weld metal parts together. After welding, the operator drops

the assembly in a transport bin ready for dispatch. As each

assembly is placed in the bin, an infra-red light detection grid

sensor detects its presence and confirms that the welding

cycle has been completed correctly

CUSTOMER APPLICATION

In an automotive 1st tier supplier manufacturing plant, an

operator loads small parts by hand onto a resistance-welding

machine and initiates the PLC-controlled welding cycle. After

welding, the operator drops the completed assembly into a

metal bin used to transport parts directly to the customer.

From time to time, unwelded parts are placed in the bin,

resulting in rejection of entire batches of assemblies by the

customer. Manual inspection of each assembly is impractical; a

sensor system must detect the presence of each item as it is

dropped into the bin and check that the corresponding

welding cycle has been completed.

The sensing system must not increase the process cycle-time

and must detect parts as they are dropped into the open bin,

which is approximately 120cm (4ft) long and 90cm (3ft) wide.

Parts are around 15cm (6in) long and a sensor with a rapid

response time is necessary to detect fast-moving items.

During manufacture of automotive parking-brake cable,

multiple strands of steel wire are twisted together, forming a

single cable. After twisting, cable passes to the next process in

an unsupported, continuous length. Occasionally, the cable

breaks, compromising safety and damaging equipment.

Although the cable’s exact path is unpredictable, a multi-

beam fibre-optic sensor detects its presence, interrupting the

process if it breaks.

CUSTOMER APPLICATION

During production of automotive parking-brake cable in a

Portuguese factory, strands of steel wire are twisted together,

forming a single cable with a nominal diameter of 3mm (0.1in).

The process operates continuously, and twisted cable passes

between successive work-stations in an unbroken length.

Between operations, the cable is largely unsupported,

assuming the form of a suspended catenary.

Occasionally, a manufacturing defect causes the cable to

break. In this event, safety is compromised and, unless

processing is halted, machine breakdowns occur. A sensor

system must detect the presence of the cable as it passes

from one operation to the next, interrupting the process if it

breaks.

Because the cable is unsupported, its path is unpredictable

and its exact position at any time, particularly in the vertical

plane, is unknown. The sensor system must detect the

presence of the cable reliably at any point within an envelope

90mm (3.5in) high and 20mm (0.75in) wide.

Customer Solution

A Contrinex photoelectric sensor system, comprising a DIN-

rail-mounted fibre-optic amplifier coupled with a multi-beam

diffuse sensing head, provides an optimal solution for this

application. With maximum switching frequencies of up to

4000 Hz and sensing distances of up to 150mm (6in), multi-

beam fibre-optic sensors are ideal for detecting fast-moving

targets. The PBTP construction of the sensing head ensures

excellent mechanical protection in the production

environment.

The 28mm-wide sensing face of the multi-beam sensor

detects targets across its entire width, providing a detection

envelope that comfortably accommodates the customer’s

90mm x 20mm requirement. Initial set-up is accomplished by

means of a manual teach-in function and integral signal-

strength LCD, following which the system operates without

manual intervention.

A 2m-long fibre cable allows remote mounting of the fibre-

optic amplifier; connection to the customer’s control system is

via an industry-standard PNP interface and an integral M8

cable connector, allowing easy removal and replacement

when necessary.

The system tolerates high ambient-light conditions and

detection of a broken cable is both highly reliable and

immediate. If the cable breaks, the system interrupts the

process and sounds an alarm, alerting the operator. Downtime

arising from broken cables has been eliminated since the

system has been operational.

Contrinex’s innovative sensors provide affordable detection of

overlapping metal sheets. They can protect a press-line by

checking that two metal blanks are not presented to the

forming press, or alternatively ensure two pieces of metal are

present for example in an automotive welding assembly –

Sometimes two’s too many, but sometimes you just need two.

CUSTOMER APPLICATION

A producer of deep-drawn metal parts for the automotive

industry uses Contrinex’s double-sheet sensing to prevent

costly tool damage and downtime.

Deep drawing and other metal-forming techniques are widely

used in the automotive industry, which requires expensive

press tools to produce complex profiles from sheet metal

blanks. During high-volume production, an automated feeder

loads sheets of steel or aluminium to the press.

The metal sheets are lightly lubricated to reduce friction

during deep drawing, but the thin film of oil can cause two

sheets to stick together in the feeder. If the press operates with

such double sheets loaded, the forming tool will be damaged,

resulting in downtime and large repair costs. Therefore

sensing systems are used to check the material before it is

loaded.

Previously, the customer had trailed alternative sensor

technologies. All were excessively cumbersome and difficult to

set up, and most were unable to detect double sheets reliably.

CUSTOMER VALUES

RELIABLE DOUBLE-SHEET DETECTION ELIMINATES TOOL

DAMAGE AND DOWNTIME

COMPACT, ROBUST SENSOR ENSURES CONVENIENT,

UNOBTRUSIVE OPERATION

INCREASED FLEXIBILITY AS A SINGLE SENSOR DETECTS

SEVERAL DIFFERENT MATERIALS (EG CARBON STEEL,

STAINLESS STEEL & ALUMINIUM)

REDUCED COMPLEXITY AS SENSOR CONNECTS DIRECTLY TO

THE CUSTOMER’S CONTROL SYSTEM

PRODUCT ADVANTAGES

SENSOR SPECIALLY DEVELOPED FOR DETECTING MULTIPLE

OVERLAPPING METAL SHEETS

CONDET® TECHNOLOGY MAKES PERFORMANCE

INDEPENDENT OF TARGET MATERIAL

RUGGED INDUCTIVE SENSOR WITH ONE-PIECE STAINLESS

STEEL CONSTRUCTION

EXTENDED SENSING DISTANCE AVOIDS RISK OF MECHANICAL

DAMAGE

Customer Solution

Contrinex offers a rugged, compact stainless-steel -bodied

sensor for the loading station, which checks each metal sheet

as it is presented by the feeder. If it detects a double sheet, the

material is rejected and the operating cycle inhibited, which

reduces expensive damage to tooling and improves OEE.

The sensor enables discrimination between single and double

metal sheets of a defined thickness of steel or aluminium in

the size range of 0.8 – 1.2mm thick.

A specialist version of Contrinex’s uniquely robust ‘700 Series’

family of inductive sensors, they share the benefits of being

both impact and abrasion resilient and having a case

machined from a single-piece of stainless-steel – These are the

sensors whose robustness is demonstrated by using them to

hammer in nails.

The reliability of their performance and robustness enable you

to minimise downtime and improve the OEE of Press-lines or

verify assembly operations.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS,

WE WILL HELP YOU SOLVE YOUR APPLICATIONS, IMPROVE MACHINE

PERFORMANCE & RELIABILITY AND REDUCE COSTS USING CONTRINEX’S

EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

During semi-automated heat staking of assemblies

manufacturers use light curtains to preserve operator safety

without compromising production throughput. The active

optoelectronic protective device (AOPD), mounted directly in

front of each bench-mounted heat-press, prevents the press-

head from descending if it detects any intrusion in the

working area, halting the operating cycle immediately.

CUSTOMER APPLICATION

Heat-staking is a popular process for fastening metal parts to

plastic moldings, and is commonly used by manufacturers

during the production of sub-assemblies. At each station, an

operator loads a molding and one or more metal parts into a

slide-mounted assembly fixture. Once the components are

correctly inserted, the operator pushes the slide into position

beneath the press-head, triggering the automated heat-

staking cycle.

The heated press-head, which may reach temperatures in

excess of 350oC (660oF), descends toward the pre-positioned

components. It applies heat and pressure to specific areas of

the molding, causing a controlled thermal deformation that

creates a permanent joint between the metal parts and the

molding. Following a pre-determined dwell period, the head

returns to the raised position, ending the cycle; the operator

withdraws the slide and removes the assembly from the

fixture.

Existing mechanical safety barriers are cumbersome and

inconvenient; throughput is constrained as a result of the time

taken to open and close the guards during each cycle. The

company requires an alternative safety guard that provides

effective hand protection while allowing unobstructed loading

and unloading. It must be simple, space-saving and operate

reliably in the production environment.