(0121) 58 222 58 SALES@PLUSAUTOMATION.CO.UK

© 2021- PLUS AUTOMATION LIMITED®

HELPING YOU #MAKE SENSE OF SENSORS

EXAMPLE APPLICATIONS

TO ILLUSTRATE THE WIDE-VARIETY OF APPLICATIONS SOLVED USING CONTRINEX SENSORS, WE HAVE POSTED A LARGE SELECTION OF EXAMPLE APPLICATIONS WHICH CAN BE SEEN BY CLICKING ON AN IMAGE. BELOW ARE A SELECTION OF SOME OF THESE APPLICATIONS:

CUSTOMER VALUES

RELIABLE, CONTINUOUS SPEED MONITORING IN HARSH

ENVIRONMENT

FIT-AND-FORGET SENSOR SOLUTION

EFFICIENT, COMPACT DESIGN POSSIBLE FOR MOBILE TURNING

MACHINE

NO SENSOR-RELATED DOWNTIME• NO REPAIR COSTS THANKS

TO EXCEPTIONALLY LONG SENSOR LIFE

PRODUCT ADVANTAGES

EXTREMELY ROBUST, IMPACT AND ABRASION RESISTANT IP68/

IP69K RATED HOUSING.

CORROSION-RESISTANT, V4A/ AISI 316L STAINLESS-STEEL,

FOOD-COMPATIBLE BODY.

LONG OPERATING DISTANCE OF 7MM IN A SMALL & SLIM

STAINLESS-STEEL 20X 32X 8MM HOUSING.

ROBUST, METAL-CASED INDUCTIVE PROXIMITY SENSORS

SUITABLE FOR EASY INTEGRATION

FACTOR 1 - CONSISTENT SENSING, IRRESPECTIVE OF WHETHER

THE TARGET IS STEEL OR ALUMINIUM.

RELIABLE, COMPACT VIBRATION-RESISTANT SENSORS

IO-LINK INTERFACE INCLUDED FOR FREE – IDEAL FOR

INDUSTRY 4

Contrinex’s Food-grade washdown rated inductive sensors are

trusted in the extremely strict hygiene regimes of dairies and

creameries. Their IP68/IP69K rated stainless-steel housings

withstand the aggressive cleaning chemicals and high-

pressure water jets in these harsh operating environments.

The robust and high-performance sensors are also trusted to

help maximise plant utilisation during round-the-clock

production.

CUSTOMER APPLICATION

Cleanliness is everything in food-processing facilities, and

nowhere more so than in the dairy industry. A single instance

of contamination during production can necessitate the

destruction of multiple batches of milk-based foodstuffs - or, if

undetected, result in illness among consumers of infected

products. It’s no surprise that for dairy-plant operators,

maintaining the strictest possible hygiene standards is an

absolute must.

Given the simultaneous need to maximise plant utilisation,

time-consuming cleaning methods are highly undesirable. To

avoid lengthy unproductive intervals between batches, food-

processing facilities commonly utilise clean-in-place (CIP) and

high-pressure washdown systems. Production equipment for

washdown areas must therefore withstand both aggressive

cleaning chemicals and high-pressure water jets as a matter of

course. This requirement extends to the sensors used

throughout these areas.

CUSTOMER SOLUTION

Contrinex’s Washdown range of food-grade inductive sensors

address these needs perfectly. Sensors from Contrinex’s ‘600

Series’ and ‘700 Series’ are certified to operate continuously

and reliably in harsh conditions.

Rated to IP68/IP69K, they are pressure-resistant up to 80 bar

(1160 Psi), corrosion-resistant and ideal for use in food and

beverage industries.

These fully embeddable inductive sensors sense the presence

and detecting the position of equipment or materials at each

stage requires sensors that are both accurate and responsive.

Contrinex Washdown inductive sensors are up to the task in all

respects. With a choice of one-piece M12, M18 or M30-diameter

one-piece AISI 316L /V4A stainless steel bodies (700 Series) or

M12-diameter AISI 316L/V4A stainless-steel body and PPS

(polyphenylene sulphide) FDA-approved sensing face (600

Series).

Flow control during milk-product processing

Most milk products, whether made from pasteurised or raw

milk, undergo a number of common manufacturing

operations during the early stages of production. Central to

these are two aspects of process manufacture that require

reliable, accurate flow-control systems: transportation and CIP.

In each case, food-grade washdown inductive sensors ensure

that the correct operating sequence is followed.

Process engineers use dedicated stainless-steel pipework to

transport liquid ingredients from one operation to the next.

Typically, fluid flow is managed using control valves fitted with

electrical, hydraulic or pneumatic actuators. Depending on

process requirements, two-way or multi-port valves, often

rotary-shaft types, deliver raw milk from holding tanks to each

process station in sequence, maintaining specified flow rates

and volumetric limits.

600 Series Washdown sensors for position sensing

Contrinex’s 600 Series Washdown sensors provide low-cost,

high-performance sensing of the position of a rotary-valve

actuator where the PPS sensing faces are not required to

withstand extremes of temperature or pressure, and the 2mm

sensing distance of these M12-diameter devices is ideally

suited to the application. These sensors interface directly with

a range of industrial process controllers and provide cost-

effective confirmation of control-valve status around the clock.

Once processing of each batch is completed and all process

vessels are drained, closed-loop CIP cleaning is initiated. In

many instances, plant managers rely on flow-transfer panels to

ensure separation of CIP and process flows; a flow-transfer

panel utilises a multi-port manifold that provides a physical

break between flow streams in accordance with good

manufacturing practices (GMPs). Connection between ports is

effected manually by means of U-shaped jumper pipes with

positional feedback from inductive sensors mounted on the

panel.

700 Series Washdown sensors for presence sensing

Manual connection carries with it a greater risk of direct

contact between assembled parts. Contrinex 700 Series Full

Inox Washdown sensors provide optimum resistance to

mechanical shocks, while offering the option of extended

sensing distances.

Multiple M30-diameter devices, positioned at predetermined

locations on each panel, sense the presence of a locating

feature on each jumper pipe, confirming that the correct ports

are interconnected before CIP cleaning is initiated. These units,

with corrosion-resistant one-piece stainless-steel housings and

a 20mm sensing distance, protect against impact damage and

also withstand accidental contact with aggressive CIP

cleaning solutions.

700 Series Washdown sensors for positional sensing

The need for accurate position sensing doesn’t end there.

Downstream processing in soft-cheese production is equally

dependent on highly reliable washdown inductive sensors for

effective control of day-to-day operations.

Curd-making is the fundamental process in cheese

production. Typically, soft-cheese curd is made in large

stainless-steel vats, where milk is mixed with a curdling agent

and heated gently, resulting in the separation of curd from the

whey. Automated knives cut the curd particles to the correct

size, following which the vat is tipped to discharge firstly the

whey, followed by the curd. Carefully controlled tipping is

essential to prevent damage to the curd. The vat rotates slowly

about a horizontally oriented support shaft.

Washdown inductive sensors from the 700 Series Full Inox

family, mounted immediately adjacent to one side of the vat,

detect the position of a cam on the shaft, confirming the

degree of angular rotation at pre-set intervals. These M18-

diameter one-piece stainless-steel devices, with a 10mm

sensing distance, match the requirements perfectly.

700 Series Washdown sensors for filling and packaging

Later, during filling and packaging operations, high-volume

soft-cheese production also relies heavily on position sensing.

Sealed tubs of cheese are conveyed from filling stations in

single lanes; pneumatic cylinders, mounted beside each

conveyor, divert multiple tubs into packing areas in

preparation for layering. In these situations, it is essential to

control the position of the ram accurately; failure to

synchronize cylinder extension with conveyor movement

results in damage to products and, potentially, to equipment.

Two M12-diameter 700 Series washdown sensors from the

Contrinex Full Inox family, embedded in the wall of each

cylinder, sense the presence of the ram as it reaches the limits

of its travel in each direction. These highly robust devices

withstand pressures of up to 80 bar (1160 psi) and operate

reliably and accurately while exposed to the working pressures

inside the cylinder.

Sensors with IO-Link communications interface

Plant-wide communication is another common requirement

for manufacturers and Contrinex offers the largest selection of

sensors with IO-Link integrated. IO-Link is a standardised

point-to-point serial connection protocol for sensors and

actuators, offering the advantages of digital communication

without the need for special cabling.

In dairy-food production, processes run continuously, with

remote diagnostics eliminating almost every need for manual

intervention. Interrogating an IO-Link-enabled device returns

its manufacturer ID and product ID, allowing systems

integrators to determine remotely that the right sensor is in

the correct location. Contrinex IO-Link washdown sensors

additionally feature an on-demand self-test function that

confirms error-free operation at all times.

Systems designers also have the capability to modify the

output signal. Delaying the switching pulse accommodates

any travel time between a sensor and its corresponding

actuation point, while stretching the pulse ensures that slave

devices with lengthy response times trigger reliably, even at

high throughput rates. Finally, each sensor provides an output-

status check derived from its factory calibration data. If the

output signal from a sensor falls outside a range that

corresponds to a sensing distance between 80% and 100% of

its nominal value, an alarm flag is triggered, highlighting the

need for investigation. For process engineers with demanding

deadlines, peace-of-mind is a valuable benefit.

Contrinex sensors for food industry

Contrinex 600 Series and 700 Series Full Inox washdown

sensors provide a robust, cost-effective and hygienic solution

for manufacturers of foods, beverages and pharmaceuticals,

whether on a local or multi-national basis. Stainless-steel

construction and the no-cost option of the industry-standard

IO-Link protocol ensures that best-in-class performance is

coupled with ultimate reliability in even the most demanding

circumstances.

CUSTOMER VALUES

MAXIMUM PLANT UTILISATION IN HYGIENIC PROCESSES

NO SENSOR-RELATED DOWNTIME

DIGITAL COMMUNICATION WITHOUT SPECIAL CABLING

OUTSTANDING PROCESS MONITORING AND CONTROL

CAPABILITIES

FAST, EASY SET-UP AND RECONFIGURATION

PRODUCT ADVANTAGES

CORROSION RESISTANT, FOOD-COMPATIBLE SENSORS

ENCLOSURE RATING IP68/69K• IO-LINK INTERFACE

EXTREMELY ROBUST FULL INOX TYPES (ONE-PIECE,

STAINLESS-STEEL HOUSING; ECOLAB CERTIFIED)

FACTOR 1 ON STEEL AND ALUMINIUM

Agriculture is using increasingly complex automation in its

machinery and an example application is in composting

machines. Contrinex’s uniquely robust V4A/ 316L stainless-steel

sensors are relied upon for operating reliably in the

challenging environment of the inside of the machine’s drive

rotor. Withstanding dust, humidity and high temperatures, the

sensors enable the machine to provide the fast drying of

materials and optimal decomposition with reliable sanitisation

being ensured.

CUSTOMER APPLICATION

The efficient turning of organic materials – loosening, lifting

and aerating – is vitally important in industrial composting.

Special mobile equipment ensures fast drying of materials,

optimal decomposition and reliable sanitisation, processing

between 500 and 6800 cubic meters of earth per hour.

A manufacturer has introduced machine speed monitoring by

sensor. A sensor located in the rotor counts the passing teeth

of a rotating mechanical disk. From the number of teeth per

second, the controller then calculates the final speed.

Perfect sensor operation is required under these particularly

harsh conditions. In addition to permanent vibration and

shaking, the inductive sensor is also constantly exposed to

dust, moisture, and temperatures from 70 to 80°C (158 to

176°F). Since the location of the sensor in the rotor is hard to

access, the sensor must be very durable and low maintenance

to avoid time-consuming repairs.

CUSTOMER VALUES

SAFE, RELIABLE OPERATION IN A HOSTILE WASHDOWN

ENVIRONMENT

NO RISK OF CROSS-CONTAMINATION BETWEEN PROCESSING

AND CLEANING SEQUENCES

EASY INTEGRATION WITH EXISTING PLANT-WIDE CONTROL

SYSTEM

COST-EFFECTIVE SOLUTION REQUIRING MINIMAL

MAINTENANCE

PRODUCT ADVANTAGES

IP68/ IP69K RATED HOUSING, FOOD-COMPATIBLE BODY

EXCEPTIONAL RESISTANCE TO SHOCK AND VIBRATION

AFFORDABLE HIGH-PERFORMANCE SENSOR WITH EXCELLENT

RELIABILITY

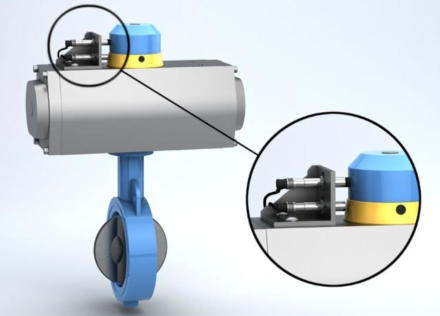

During manufacture of dairy products, raw milk travels

between successive processes through stainless-steel

pipework. Rotary-shaft control valves maintain process

sequences correctly, ensuring that no cross-contamination

occurs during CIP cleaning after each batch is completed.

Robust washdown inductive sensors, mounted on existing

rotary actuators, monitor control-valve status around the clock,

providing real-time positional feedback to a plant-wide control

system in a simple, cost-effective manner.

CUSTOMER APPLICATION

At a European dairy-processing plant, milk products, made

from pasteurized or raw milk, require hygienic transportation

between successive operations. Process engineers use

stainless-steel pipework to transport liquid ingredients from

one operation to the next. Fluid flow is managed using control

valves fitted with electrical, hydraulic or pneumatic actuators.

Multiple rotary-shaft valves deliver raw milk from holding

tanks to each process station in sequence, maintaining

specified flow rates and volumetric limits. Once processing of

each batch is completed and all process vessels are drained,

closed-loop CIP cleaning commences. Accurate, repeatable

valve sequencing is essential to prevent any chance of cross-

contamination between processing and cleaning sequences.

A robust, highly reliable sensor system, capable of

withstanding the harsh washdown regimes in force, is needed

to monitor control-valve positions during processing. Where

possible, sensors must be mounted on existing rotary

actuators, and real-time communication with existing plant-

wide control systems is mandatory.

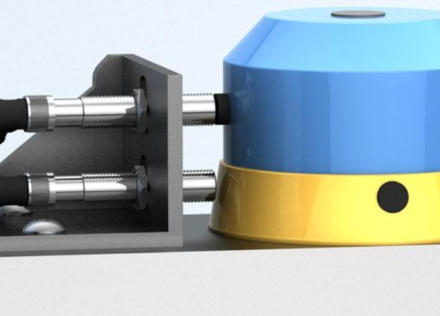

Customer Solution

Sensing the position of a rotary-valve actuator is a routine task

for Contrinex Classics washdown inductive sensors. These

sensors interface directly with a range of industrial process

controllers and provide cost-effective confirmation of control-

valve status around the clock.

A purpose-designed bracket, mounted on the top surface of

each actuator, holds two sensors; these are positioned with the

sensing faces vertically aligned, one above the other, and

facing the actuator shaft. NAMUR-compatible (VDE/VDI 3845)

mountings on the actuators provide a known datum for the

sensors.

A solid plastic disc, mounted on the shaft, carries two or more

stainless-steel targets, positioned at 90 degrees to each other

around the outer peripheral surface of the disc. Each target

occupies either an upper or a lower position corresponding to

height of one of the sensors. As the shaft rotates, opening and

closing the valve, the targets pass in front of the sensing faces,

triggering the sensors.

These M12-diameter devices, rated to IP68/IP69K, have all-

metal bodies with PBTB sensing faces and vacuum-

encapsulated electronics; each features an industry-standard

PNP normally open output. Fully embeddable, and with a

sensing range up to 2mm, they are well suited to the hostile

operating conditions of a washdown environment.

Each sensor has an integral M12 connector, interfacing with

the customer’s control system via a TPE-S-sheathed cable.

Reliability is excellent; the system is simple and cost-effective.

THE INNOVATIVE 700-SERIES INDUCTIVE SENSOR FAMILY ALSO INCLUDES ENHANCED CORROSION

RESISTANCE WITH THE ‘WASHDOWN’ 316L/ V4A STAINLESS-STEEL VERSIONS.

ENHANCED CORROSION RESISTANCE WITH ‘HAMMER-PROOF’ ROBUSTNESS GIVES A SENSOR THAT

SURVIVES A PIRANHA ATTACK OR HELPS BUILD RELIABLE MACHINES FOR CHALLENGING ENVIRONMENTS

- IMAGINE HOW THEY CAN REDUCE DOWN-TIME.

WASHDOWN 316L/V4A STAINLESS-

STEEL 700 SERIES INDUCTIVE SENSORS

CUSTOMER SOLUTION

Contrinex inductive sensors from the FULL stainless-steel

family, WASHDOWN range, are perfect for this application.

Made from a single piece of V4A stainless steel, including the

sensing face, they have no covers, caps or welding seams and

are the most robust inductive sensors on the market. They

resist shock, vibration, impact and abrasion and almost any

exposure to dirt, gases, or liquids such as oil, water and

cleaning agents. Functionally stable at temperatures from -25

to +85°C (-13 to 185°F), they are also insensitive to core

breakage.

Thanks to the long operating distances of these sensors (three

times greater than the norm) a compact and efficient design

was possible using the M12 size. A long operating distance

allows the sensor to be mounted well away from the rotating

disk’s passing teeth. Setup is also straightforward, as

installation tolerances are less critical. A sensor version with

plug connector was chosen to allow speedy replacement if

necessary.

316L/V4A WASHDOWN STAINLESS-STEEL INDUCTIVE SENSORS - ‘HAMMER HOME’ AN ADVANTAGE

PRODUCT ADVANTAGES

WORLD CLASS PERFORMANCE IN EXTREME ENVIRONMENTS

CORROSION-RESISTANT V4A/AISI 316L STAINLESS-STEEL

BODY

EXTREMELY ROBUST, IMPACT & ABRASION RESISTANT ONE-

PIECE, STAINLESS-STEEL HOUSING IP68/ IP69K/ ECOLAB®

FACTOR 1 WITH BOTH FERROUS AND NON-FERROUS

MATERIALS INCLUDING ALUMINIUM & BRASS FOR EXTENDED

SENSING

CAN OPERATE IN CLOSE PROXIMITY WITHOUT INTERFERENCE

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

Exceptional performance combined with unique robustness, Contrinex’s Full stainless-steel WASHDOWN inductive sensors are

certified to operate continuously and reliably in the harsh conditions of the food, beverage and pharmaceutical industries, ensuring

uninterrupted production.

WASHDOWN sensors are available in totally impervious one-piece V4A / AISI 316L stainless-steel M12, M18 and M30 housings, which

are machined from a solid piece so their is no joint to the sensing face. They are therefore highly resistant to the corrosive chemicals

used for clean-in-place CIP or wash-down processes. - ECOLAB approved and IP68 / IP69K rated they are pressure resistant up to 80

bar, food safe and corrosion resistant.

WATCH THE VIDEO TO SEE THE UNIQUE

ROBUSTNESS DEMONSTRATED

WATCH THE VIDEO TO SEE THE UNIQUE

ROBUSTNESS SURVIVE PIRANHAS

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS, WE WILL WORK TO HELP YOU

SOLVE YOUR APPLICATIONS, IMPROVE MACHINE PERFORMANCE & RELIABILITY AND REDUCE COSTS

USING CONTRINEX’S EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

The ‘700’ Series ‘Extreme’ sensors are uniquely robust sensors

are typically demonstrated by Contrinex as being able to

repeatedly being used to hammer in nails. Even when their

front face is dented, the sensor continues to operate correctly.

Even under the harsh operating conditions of this application,

these sensors last several years and downtime attributable to

faulty sensors is minimal. Their long service life contributes to a

reduction in repair costs.

CLICK ON AN IMAGE TO VIEW THE BROCHURE

OR VIDEO, READ APPLICATION EXAMPLES BELOW,

CLICK HERE TO VIEW THIS SENSOR ON

CONTRINEX’S WEBSITE, OR CALL US TO HELP GUIDE

YOU THROUGH SELECTION, ANSWER QUESTIONS,

OR TO HELP YOU #MAKESENSEOFSENSORS:

WASHDOWN 316L/V4A

STAINLESS-STEEL 700

SERIES INDUCTIVE SENSORS

THE INNOVATIVE 700-SERIES INDUCTIVE SENSOR

FAMILY ALSO INCLUDES ENHANCED CORROSION

RESISTANCE WITH THE ‘WASHDOWN’

316L/ V4A STAINLESS-STEEL VERSIONS.

ENHANCED CORROSION RESISTANCE WITH ‘HAMMER-

PROOF’ ROBUSTNESS GIVES A SENSOR THAT SURVIVES A

PIRANHA ATTACK OR HELPS BUILD RELIABLE MACHINES

FOR CHALLENGING ENVIRONMENTS

- IMAGINE HOW THEY CAN REDUCE DOWN-TIME.

During manufacture of dairy products, raw milk travels

between successive processes through stainless-steel

pipework. Rotary-shaft control valves maintain process

sequences correctly, ensuring that no cross-contamination

occurs during CIP cleaning after each batch is completed.

Robust washdown inductive sensors, mounted on existing

rotary actuators, monitor control-valve status around the clock,

providing real-time positional feedback to a plant-wide control

system in a simple, cost-effective manner.

CUSTOMER APPLICATION

At a European dairy-processing plant, milk products, made

from pasteurized or raw milk, require hygienic transportation

between successive operations. Process engineers use

stainless-steel pipework to transport liquid ingredients from

one operation to the next. Fluid flow is managed using control

valves fitted with electrical, hydraulic or pneumatic actuators.

Multiple rotary-shaft valves deliver raw milk from holding

tanks to each process station in sequence, maintaining

specified flow rates and volumetric limits. Once processing of

each batch is completed and all process vessels are drained,

closed-loop CIP cleaning commences. Accurate, repeatable

valve sequencing is essential to prevent any chance of cross-

contamination between processing and cleaning sequences.

A robust, highly reliable sensor system, capable of

withstanding the harsh washdown regimes in force, is needed

to monitor control-valve positions during processing. Where

possible, sensors must be mounted on existing rotary

actuators, and real-time communication with existing plant-

wide control systems is mandatory.

CUSTOMER SOLUTION

Contrinex inductive sensors from the FULL stainless-steel

family, WASHDOWN range, are perfect for this application.

Made from a single piece of V4A stainless steel, including the

sensing face, they have no covers, caps or welding seams and

are the most robust inductive sensors on the market. They

resist shock, vibration, impact and abrasion and almost any

exposure to dirt, gases, or liquids such as oil, water and

cleaning agents. Functionally stable at temperatures from -25

to +85°C (-13 to 185°F), they are also insensitive to core

breakage.

Thanks to the long operating distances of these sensors (three

times greater than the norm) a compact and efficient design

was possible using the M12 size. A long operating distance

allows the sensor to be mounted well away from the rotating

disk’s passing teeth. Setup is also straightforward, as

installation tolerances are less critical. A sensor version with

plug connector was chosen to allow speedy replacement if

necessary.

Agriculture is using increasingly complex automation in its

machinery and an example application is in composting

machines. Contrinex’s uniquely robust V4A/ 316L stainless-steel

sensors are relied upon for operating reliably in the

challenging environment of the inside of the machine’s drive

rotor. Withstanding dust, humidity and high temperatures, the

sensors enable the machine to provide the fast drying of

materials and optimal decomposition with reliable sanitisation

being ensured.

CUSTOMER APPLICATION

The efficient turning of organic materials – loosening, lifting

and aerating – is vitally important in industrial composting.

Special mobile equipment ensures fast drying of materials,

optimal decomposition and reliable sanitisation, processing

between 500 and 6800 cubic meters of earth per hour.

A manufacturer has introduced machine speed monitoring by

sensor. A sensor located in the rotor counts the passing teeth

of a rotating mechanical disk. From the number of teeth per

second, the controller then calculates the final speed.

Perfect sensor operation is required under these particularly

harsh conditions. In addition to permanent vibration and

shaking, the inductive sensor is also constantly exposed to

dust, moisture, and temperatures from 70 to 80°C (158 to

176°F). Since the location of the sensor in the rotor is hard to

access, the sensor must be very durable and low maintenance

to avoid time-consuming repairs.

APPLICATION - ‘TURNING OVER AN OLD-

LEAF’ - COMPOST TURNING MACHINE

Customer Solution

Sensing the position of a rotary-valve actuator is a routine task

for Contrinex Classics washdown inductive sensors. These

sensors interface directly with a range of industrial process

controllers and provide cost-effective confirmation of control-

valve status around the clock.

A purpose-designed bracket, mounted on the top surface of

each actuator, holds two sensors; these are positioned with the

sensing faces vertically aligned, one above the other, and

facing the actuator shaft. NAMUR-compatible (VDE/VDI 3845)

mountings on the actuators provide a known datum for the

sensors.

A solid plastic disc, mounted on the shaft, carries two or more

stainless-steel targets, positioned at 90 degrees to each other

around the outer peripheral surface of the disc. Each target

occupies either an upper or a lower position corresponding to

height of one of the sensors. As the shaft rotates, opening and

closing the valve, the targets pass in front of the sensing faces,

triggering the sensors.

These M12-diameter devices, rated to IP68/IP69K, have all-

metal bodies with PBTB sensing faces and vacuum-

encapsulated electronics; each features an industry-standard

PNP normally open output. Fully embeddable, and with a

sensing range up to 2mm, they are well suited to the hostile

operating conditions of a washdown environment.

Each sensor has an integral M12 connector, interfacing with

the customer’s control system via a TPE-S-sheathed cable.

Reliability is excellent; the system is simple and cost-effective.

CUSTOMER VALUES

RELIABLE, CONTINUOUS SPEED MONITORING IN HARSH

ENVIRONMENT

FIT-AND-FORGET SENSOR SOLUTION

EFFICIENT, COMPACT DESIGN POSSIBLE FOR MOBILE TURNING

MACHINE

NO SENSOR-RELATED DOWNTIME• NO REPAIR COSTS THANKS

TO EXCEPTIONALLY LONG SENSOR LIFE

PRODUCT ADVANTAGES

EXTREMELY ROBUST, IMPACT AND ABRASION RESISTANT IP68/

IP69K RATED HOUSING.

CORROSION-RESISTANT, V4A/ AISI 316L STAINLESS-STEEL,

FOOD-COMPATIBLE BODY.

LONG OPERATING DISTANCE OF 7MM IN A SMALL & SLIM

STAINLESS-STEEL 20X 32X 8MM HOUSING.

ROBUST, METAL-CASED INDUCTIVE PROXIMITY SENSORS

SUITABLE FOR EASY INTEGRATION

FACTOR 1 - CONSISTENT SENSING, IRRESPECTIVE OF WHETHER

THE TARGET IS STEEL OR ALUMINIUM.

RELIABLE, COMPACT VIBRATION-RESISTANT SENSORS

IO-LINK INTERFACE INCLUDED FOR FREE – IDEAL FOR

INDUSTRY 4

The ‘700’ Series ‘Extreme’ sensors are uniquely robust sensors

are typically demonstrated by Contrinex as being able to

repeatedly being used to hammer in nails. Even when their

front face is dented, the sensor continues to operate correctly.

Even under the harsh operating conditions of this application,

these sensors last several years and downtime attributable to

faulty sensors is minimal. Their long service life contributes to a

reduction in repair costs.

WATCH THE VIDEO TO SEE THE UNIQUE

ROBUSTNESS DEMONSTRATED

WATCH THE VIDEO TO SEE THE UNIQUE

ROBUSTNESS SURVIVE PIRANHAS

316L/V4A WASHDOWN STAINLESS-

STEEL INDUCTIVE SENSORS

- ‘HAMMER HOME’ AN ADVANTAGE

PRODUCT ADVANTAGES

WORLD CLASS PERFORMANCE IN EXTREME ENVIRONMENTS

CORROSION-RESISTANT V4A/AISI 316L STAINLESS-STEEL

BODY

EXTREMELY ROBUST, IMPACT & ABRASION RESISTANT ONE-

PIECE, STAINLESS-STEEL HOUSING IP68/ IP69K/ ECOLAB®

FACTOR 1 WITH BOTH FERROUS AND NON-FERROUS

MATERIALS INCLUDING ALUMINIUM & BRASS FOR EXTENDED

SENSING

CAN OPERATE IN CLOSE PROXIMITY WITHOUT INTERFERENCE

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

CUSTOMER VALUES

MAXIMUM PLANT UTILISATION IN HYGIENIC PROCESSES

NO SENSOR-RELATED DOWNTIME

DIGITAL COMMUNICATION WITHOUT SPECIAL CABLING

OUTSTANDING PROCESS MONITORING AND CONTROL

CAPABILITIES

FAST, EASY SET-UP AND RECONFIGURATION

PRODUCT ADVANTAGES

CORROSION RESISTANT, FOOD-COMPATIBLE SENSORS

ENCLOSURE RATING IP68/69K• IO-LINK INTERFACE

EXTREMELY ROBUST FULL INOX TYPES (ONE-PIECE,

STAINLESS-STEEL HOUSING; ECOLAB CERTIFIED)

FACTOR 1 ON STEEL AND ALUMINIUM

CUSTOMER VALUES

SAFE, RELIABLE OPERATION IN A HOSTILE WASHDOWN

ENVIRONMENT

NO RISK OF CROSS-CONTAMINATION BETWEEN PROCESSING

AND CLEANING SEQUENCES

EASY INTEGRATION WITH EXISTING PLANT-WIDE CONTROL

SYSTEM

COST-EFFECTIVE SOLUTION REQUIRING MINIMAL

MAINTENANCE

PRODUCT ADVANTAGES

IP68/ IP69K RATED HOUSING, FOOD-COMPATIBLE BODY

EXCEPTIONAL RESISTANCE TO SHOCK AND VIBRATION

AFFORDABLE HIGH-PERFORMANCE SENSOR WITH EXCELLENT

RELIABILITY

Exceptional performance combined with unique robustness,

Contrinex’s Full stainless-steel WASHDOWN inductive sensors

are certified to operate continuously and reliably in the harsh

conditions of the food, beverage and pharmaceutical industries,

ensuring uninterrupted production.

WASHDOWN sensors are available in totally impervious one-

piece V4A / AISI 316L stainless-steel M12, M18 and M30 housings,

which are machined from a solid piece so their is no joint to the

sensing face. They are therefore highly resistant to the corrosive

chemicals used for clean-in-place CIP or wash-down processes.

- ECOLAB approved and IP68 / IP69K rated they are pressure

resistant up to 80 bar, food safe and corrosion resistant.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS,

WE WORK TO HELP YOU SOLVE YOUR APPLICATIONS, IMPROVE MACHINE

PERFORMANCE & RELIABILITY AND REDUCE COSTS USING CONTRINEX’S

EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

Contrinex’s Food-grade washdown rated inductive sensors are

trusted in the extremely strict hygiene regimes of dairies and

creameries. Their IP68/IP69K rated stainless-steel housings

withstand the aggressive cleaning chemicals and high-

pressure water jets in these harsh operating environments.

The robust and high-performance sensors are also trusted to

help maximise plant utilisation during round-the-clock

production.

CUSTOMER APPLICATION

Cleanliness is everything in food-processing facilities, and

nowhere more so than in the dairy industry. A single instance

of contamination during production can necessitate the

destruction of multiple batches of milk-based foodstuffs - or, if

undetected, result in illness among consumers of infected

products. It’s no surprise that for dairy-plant operators,

maintaining the strictest possible hygiene standards is an

absolute must.

Given the simultaneous need to maximise plant utilisation,

time-consuming cleaning methods are highly undesirable. To

avoid lengthy unproductive intervals between batches, food-

processing facilities commonly utilise clean-in-place (CIP) and

high-pressure washdown systems. Production equipment for

washdown areas must therefore withstand both aggressive

cleaning chemicals and high-pressure water jets as a matter of

course. This requirement extends to the sensors used

throughout these areas.

CUSTOMER SOLUTION

Contrinex’s Washdown range of food-grade inductive sensors

address these needs perfectly. Sensors from Contrinex’s ‘600

Series’ and ‘700 Series’ are certified to operate continuously

and reliably in harsh conditions.

Rated to IP68/IP69K, they are pressure-resistant up to 80 bar

(1160 Psi), corrosion-resistant and ideal for use in food and

beverage industries.

These fully embeddable inductive sensors sense the presence

and detecting the position of equipment or materials at each

stage requires sensors that are both accurate and responsive.

Contrinex Washdown inductive sensors are up to the task in all

respects. With a choice of one-piece M12, M18 or M30-diameter

one-piece AISI 316L /V4A stainless steel bodies (700 Series) or

M12-diameter AISI 316L/V4A stainless-steel body and PPS

(polyphenylene sulphide) FDA-approved sensing face (600

Series).

Flow control during milk-product processing

Most milk products, whether made from pasteurised or raw

milk, undergo a number of common manufacturing

operations during the early stages of production. Central to

these are two aspects of process manufacture that require

reliable, accurate flow-control systems: transportation and CIP.

In each case, food-grade washdown inductive sensors ensure

that the correct operating sequence is followed.

Process engineers use dedicated stainless-steel pipework to

transport liquid ingredients from one operation to the next.

Typically, fluid flow is managed using control valves fitted with

electrical, hydraulic or pneumatic actuators. Depending on

process requirements, two-way or multi-port valves, often

rotary-shaft types, deliver raw milk from holding tanks to each

process station in sequence, maintaining specified flow rates

and volumetric limits.

600 Series Washdown sensors for position sensing

Contrinex’s 600 Series Washdown sensors provide low-cost,

high-performance sensing of the position of a rotary-valve

actuator where the PPS sensing faces are not required to

withstand extremes of temperature or pressure, and the 2mm

sensing distance of these M12-diameter devices is ideally

suited to the application. These sensors interface directly with

a range of industrial process controllers and provide cost-

effective confirmation of control-valve status around the clock.

Once processing of each batch is completed and all process

vessels are drained, closed-loop CIP cleaning is initiated. In

many instances, plant managers rely on flow-transfer panels to

ensure separation of CIP and process flows; a flow-transfer

panel utilises a multi-port manifold that provides a physical

break between flow streams in accordance with good

manufacturing practices (GMPs). Connection between ports is

effected manually by means of U-shaped jumper pipes with

positional feedback from inductive sensors mounted on the

panel.

700 Series Washdown sensors for presence sensing

Manual connection carries with it a greater risk of direct

contact between assembled parts. Contrinex 700 Series Full

Inox Washdown sensors provide optimum resistance to

mechanical shocks, while offering the option of extended

sensing distances.

Multiple M30-diameter devices, positioned at predetermined

locations on each panel, sense the presence of a locating

feature on each jumper pipe, confirming that the correct ports

are interconnected before CIP cleaning is initiated. These units,

with corrosion-resistant one-piece stainless-steel housings and

a 20mm sensing distance, protect against impact damage and

also withstand accidental contact with aggressive CIP

cleaning solutions.

700 Series Washdown sensors for positional sensing

The need for accurate position sensing doesn’t end there.

Downstream processing in soft-cheese production is equally

dependent on highly reliable washdown inductive sensors for

effective control of day-to-day operations.

Curd-making is the fundamental process in cheese

production. Typically, soft-cheese curd is made in large

stainless-steel vats, where milk is mixed with a curdling agent

and heated gently, resulting in the separation of curd from the

whey. Automated knives cut the curd particles to the correct

size, following which the vat is tipped to discharge firstly the

whey, followed by the curd. Carefully controlled tipping is

essential to prevent damage to the curd. The vat rotates slowly

about a horizontally oriented support shaft.

Washdown inductive sensors from the 700 Series Full Inox

family, mounted immediately adjacent to one side of the vat,

detect the position of a cam on the shaft, confirming the

degree of angular rotation at pre-set intervals. These M18-

diameter one-piece stainless-steel devices, with a 10mm

sensing distance, match the requirements perfectly.

700 Series Washdown sensors for filling and packaging

Later, during filling and packaging operations, high-volume

soft-cheese production also relies heavily on position sensing.

Sealed tubs of cheese are conveyed from filling stations in

single lanes; pneumatic cylinders, mounted beside each

conveyor, divert multiple tubs into packing areas in

preparation for layering. In these situations, it is essential to

control the position of the ram accurately; failure to

synchronize cylinder extension with conveyor movement

results in damage to products and, potentially, to equipment.

Two M12-diameter 700 Series washdown sensors from the

Contrinex Full Inox family, embedded in the wall of each

cylinder, sense the presence of the ram as it reaches the limits

of its travel in each direction. These highly robust devices

withstand pressures of up to 80 bar (1160 psi) and operate

reliably and accurately while exposed to the working pressures

inside the cylinder.

Sensors with IO-Link communications interface

Plant-wide communication is another common requirement

for manufacturers and Contrinex offers the largest selection of

sensors with IO-Link integrated. IO-Link is a standardised

point-to-point serial connection protocol for sensors and

actuators, offering the advantages of digital communication

without the need for special cabling.

In dairy-food production, processes run continuously, with

remote diagnostics eliminating almost every need for manual

intervention. Interrogating an IO-Link-enabled device returns

its manufacturer ID and product ID, allowing systems

integrators to determine remotely that the right sensor is in

the correct location. Contrinex IO-Link washdown sensors

additionally feature an on-demand self-test function that

confirms error-free operation at all times.

Systems designers also have the capability to modify the

output signal. Delaying the switching pulse accommodates

any travel time between a sensor and its corresponding

actuation point, while stretching the pulse ensures that slave

devices with lengthy response times trigger reliably, even at

high throughput rates. Finally, each sensor provides an output-

status check derived from its factory calibration data. If the

output signal from a sensor falls outside a range that

corresponds to a sensing distance between 80% and 100% of

its nominal value, an alarm flag is triggered, highlighting the

need for investigation. For process engineers with demanding

deadlines, peace-of-mind is a valuable benefit.

Contrinex sensors for food industry

Contrinex 600 Series and 700 Series Full Inox washdown

sensors provide a robust, cost-effective and hygienic solution

for manufacturers of foods, beverages and pharmaceuticals,

whether on a local or multi-national basis. Stainless-steel

construction and the no-cost option of the industry-standard

IO-Link protocol ensures that best-in-class performance is

coupled with ultimate reliability in even the most demanding

circumstances.