(0121) 58 222 58 SALES@PLUSAUTOMATION.CO.UK

© 2021 - PLUS AUTOMATION LIMITED®

HELPING YOU #MAKE SENSE OF SENSORS

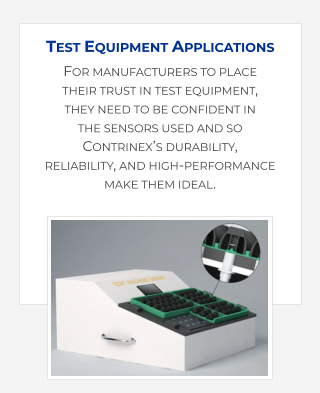

EXAMPLE APPLICATIONS

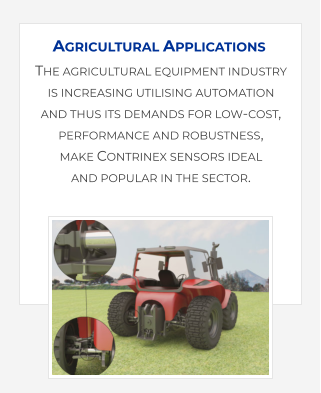

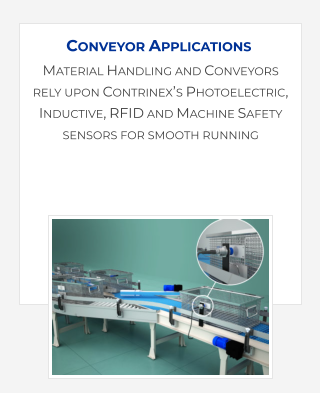

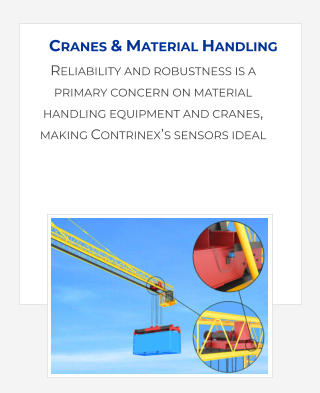

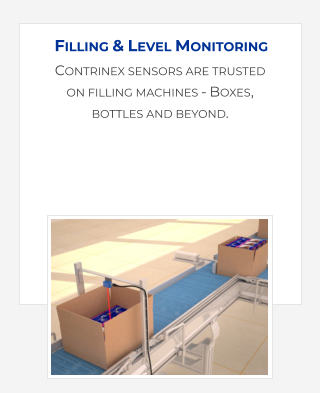

TO ILLUSTRATE THE WIDE-VARIETY OF APPLICATIONS SOLVED USING CONTRINEX SENSORS, WE HAVE POSTED A LARGE SELECTION OF EXAMPLE APPLICATIONS WHICH CAN BE SEEN BY CLICKING ON AN IMAGE. BELOW ARE A SELECTION OF SOME OF THESE APPLICATIONS:

SWISS COMPANIES HAVE A REPUTATION FOR PRECISION AND CONTRINEX COMBINES THIS

WITH CLEVER ENGINEERING IN IT’S INNOVATIVE LIGHT-GRIDS TO GIVE FAST & SIMPLE

IMPLEMENTATION, WITH LOW PRICES, WHICH MEANS LOWER COSTS.

MEASUREMENT & DETECTION LIGHT GRIDS

Contrinex’s innovative infrared light-grids offer fast response times and reliable detection of varied objects with powerful immunity

to interference from ambient light. It also provide fast and simple implementation, plus low cost measurement or detection.

The measurement light-grid works like a conventional analogue sensor, with either a 0 to 10V or 4 to 20mA output - There is no

data-stream to analyse, removing the need for expensive and complex processing. Set-up, therefore really takes less than 60

seconds.

Similarly, the detection light-grid provides a switched output just like any

through-beam photoelectric sensor.

Potential applications for these keen-eyed, robust sensors are to be found in such

fields of application as logistics or automated packaging systems and in harsh

environments such as warehouses and conveyors.

Contrinex’s DGI detection and MGI measurement grids offer compact and robust

plug-and-play solutions. With a cross-section of only 40 x 20.5mm, these space-

saving devices are easily integrated into different systems.

DGI detection types offer detection heights up to 2010 mm and are capable of detecting objects with diameters of 0.9, 2, 4, 8 or 25

mm, depending on type. With response times between 0.8 and 4.8 ms, even small objects moving at high speed can be reliably

detected and counted. Fields of application include the production of small parts or foil, packaging equipment and the

pharmaceutical industry.

In addition to detecting the presence of an object, MGI measurement types can also determine its dimensions and position. These

sensors offer measurement heights up to 1438mm and a resolution of 5 or 12mm. Measurements are output as analogue values of

0-10V or as a 4-20mA signal.

.

CUSTOMER VALUES

PROVEN TECHNOLOGY TO ENSURE HIGHLY RELIABLE FIT-&-

FORGET POKA YOKE QUALITY CONTROL WITH NO MANUAL

INTERVENTION

UNOBTRUSIVE SYSTEM THAT DOES NOT IMPACT UPON THE

WELDING STATION CYCYLE TIMES

FAST & EASY SWAP OUT IN CASE OF DAMAGE TO THE SENSOR

PRODUCT ADVANTAGES

COMPACT & ROBUST, ALUMINIUM EXTRUDED HOUSING - 40 X

20.5MM

EXCEPTIONAL RANGE OF SIZES - 100MM TO 2M PROTECTION

WIDTH WITH RESOLUTIONS FROM 0.9 TO 25MM

FAST & EASY INTEGRATION WITH M12 CONNECTORS

LOW COST, HIGH PERFORMANCE AND LONG SENSING RANGE

During manufacture of mechanical assemblies for automotive

production, an operator uses a manually operated machine to

assemble metal parts together. After assembly the operator

drops the assembly in a transport bin ready for dispatch. As

each assembly is placed in the bin, an infra-red light detection

grid sensor detects its presence and confirms that the welding

cycle has been completed correctly

CUSTOMER APPLICATION

In an automotive 1st tier supplier manufacturing plant, an

operator loads small parts by hand onto an assembly machine

and initiates the PLC-controlled cycle. After assembly the

operator drops the completed assembly into a metal bin used

to transport parts directly to the customer.

From time to time, un-assembled parts are placed in the bin,

resulting in rejection of entire batches of assemblies by the

customer. Manual inspection of each assembly is impractical; a

sensor system must detect the presence of each item as it is

dropped into the bin and check that the corresponding

welding cycle has been completed.

The sensing system must not increase the process cycle-time

and must detect parts as they are dropped into the open bin,

which is approximately 120cm (4ft) long and 90cm (3ft) wide.

Parts are around 15cm (6in) long and a sensor with a rapid

response time is necessary to detect fast-moving items.

Customer Solution

The Contrinex DGI range of infrared light detection grids is

well-suited for this application. Comprising separate sender-

and receiver-units and constructed with rugged one-piece

aluminium-profile housings, these versatile sensor systems are

ideal for the busy production environment.

With response times from 0.8 to 4.8 milliseconds which are

faster than safety light-curtains and a choice of resolutions

from 0.9 to 25mm dependent upon the size of the light grid,

the DGI light detection grids range exceed the demanding

customer specification for rapid response and reliable

detection of the small parts.

The 8m range between sender and receiver and their compact

design enables easy mounting at each end of the transport

bin without impeding the operator or increasing the process

cycle time.

The DGI light detection grid sender only requires a power

supply connection and the receiver features two Push-Pull

(PNP + NPN), Light-ON+ Dark-ON, 4-pin M12 outputs,

simplifying installation.

The system detects the presence of any item passing through

the light curtain and immediately interrogates the PLC to

confirm that a welding cycle has been completed since

detection of the preceding item. If no welding cycle is

registered, the system interrupts the process and sounds an

alarm, alerting the operator.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS, WE WILL WORK TO HELP YOU

SOLVE YOUR APPLICATIONS, IMPROVE MACHINE PERFORMANCE & RELIABILITY AND REDUCE COSTS

USING CONTRINEX’S EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

DGI types offer detection heights up to 2010 mm and are

capable of detecting objects with diameters of 0.9, 2, 4, 8 or 25

mm, depending on type. With response times between 0.8

and 4.8 ms, even small objects moving at high speed can be

reliably detected and counted. Fields of application include the

production of small parts or foil, packaging equipment and the

pharmaceutical industry.

In addition to detecting the presence of an object, MGI

measurement types can also determine its dimensions and

position. These sensors offer measurement heights up to

1438mm and a resolution of 5 or 12mm. Measurements are

output as analogue values of 0-10V or as a 4-20mA signal.

CLICK ON AN IMAGE TO VIEW THE BROCHURE,

OR CLICK HERE TO VIEW THIS SENSOR ON

CONTRINEX’S WEBSITE, OR CALL US TO HELP

GUIDE YOU THROUGH SELECTION, ANSWER

QUESTIONS, OR TO HELP YOU

#MAKESENSEOFSENSORS:

MEASUREMENT &

DETECTION LIGHT GRIDS

SWISS COMPANIES HAVE A REPUTATION FOR

PRECISION AND CONTRINEX COMBINES THIS WITH

CLEVER ENGINEERING IN IT’S INNOVATIVE LIGHT-

GRIDS TO GIVE FAST & SIMPLE IMPLEMENTATION,

WITH LOW PRICES, WHICH MEANS LOWER COSTS

DETECTION & MEASUREMENT LIGHT GRIDS - SWISS

PRECISION THAT IS FAST & EASY TO IMPLEMENT

Contrinex’s innovative infrared light-grids offer fast response

times and reliable detection of varied objects with powerful

immunity to interference from ambient light. It also provide

fast and simple implementation, plus low cost measurement

or detection.

The measurement light-grid works like a conventional

analogue sensor, with either a 0 to 10v or 4 to 20mA output -

There is no data-stream to analyse, removing the need for

expensive and complex processing. Set-up, therefore really

takes less than 60 seconds.

Similarly, the detection light-grid provides a switched output

just like any through-beam photoelectric sensor.

Potential applications for these keen-eyed, robust sensors are

to be found in such fields of application as logistics or

automated packaging systems and in harsh environments

such as warehouses and conveyors.

With the DGI (detection) and MGI (measurement) series,

Contrinex offers compact infrared light grids in a robust plug-

and-play solution. With a cross-section of only 40 x 20.5 mm,

these space-saving devices are easily integrated into different

systems.

.

Customer Solution

The Contrinex DGI range of infrared light detection grids is

well-suited for this application. Comprising separate sender-

and receiver-units and constructed with rugged one-piece

aluminium-profile housings, these versatile sensor systems are

ideal for the busy production environment.

With response times from 0.8 to 4.8 milliseconds which are

faster than safety light-curtains and a choice of resolutions

from 0.9 to 25mm dependent upon the size of the light grid,

the DGI light detection grids range exceed the demanding

customer specification for rapid response and reliable

detection of the small parts.

The 8m range between sender and receiver and their compact

design enables easy mounting at each end of the transport

bin without impeding the operator or increasing the process

cycle time.

The DGI light detection grid sender only requires a power

supply connection and the receiver features two Push-Pull

(PNP + NPN), Light-ON+ Dark-ON, 4-pin M12 outputs,

simplifying installation.

The system detects the presence of any item passing through

the light curtain and immediately interrogates the PLC to

confirm that a welding cycle has been completed since

detection of the preceding item. If no welding cycle is

registered, the system interrupts the process and sounds an

alarm, alerting the operator.

CUSTOMER VALUES

PROVEN TECHNOLOGY TO ENSURE HIGHLY RELIABLE FIT-&-

FORGET POKA YOKE QUALITY CONTROL WITH NO MANUAL

INTERVENTION

UNOBTRUSIVE SYSTEM THAT DOES NOT IMPACT UPON THE

WELDING STATION CYCYLE TIMES

FAST & EASY SWAP OUT IN CASE OF DAMAGE TO THE SENSOR

PRODUCT ADVANTAGES

COMPACT & ROBUST, ALUMINIUM EXTRUDED HOUSING - 40 X

20.5MM

EXCEPTIONAL RANGE OF SIZES - 100MM TO 2M PROTECTION

WIDTH WITH RESOLUTIONS FROM 0.9 TO 25MM

FAST & EASY INTEGRATION WITH M12 CONNECTORS

LOW COST, HIGH PERFORMANCE AND LONG SENSING RANGE

During manufacture of mechanical assemblies for automotive

production, an operator uses a manually operated machine to

assemble metal parts together. After assembly the operator

drops the assembly in a transport bin ready for dispatch. As

each assembly is placed in the bin, an infra-red light detection

grid sensor detects its presence and confirms that the welding

cycle has been completed correctly

CUSTOMER APPLICATION

In an automotive 1st tier supplier manufacturing plant, an

operator loads small parts by hand onto an assembly machine

and initiates the PLC-controlled cycle. After assembly the

operator drops the completed assembly into a metal bin used

to transport parts directly to the customer.

From time to time, un-assembled parts are placed in the bin,

resulting in rejection of entire batches of assemblies by the

customer. Manual inspection of each assembly is impractical; a

sensor system must detect the presence of each item as it is

dropped into the bin and check that the corresponding

welding cycle has been completed.

The sensing system must not increase the process cycle-time

and must detect parts as they are dropped into the open bin,

which is approximately 120cm (4ft) long and 90cm (3ft) wide.

Parts are around 15cm (6in) long and a sensor with a rapid

response time is necessary to detect fast-moving items.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS,

WE WORK TO HELP YOU SOLVE YOUR APPLICATIONS, IMPROVE MACHINE

PERFORMANCE & RELIABILITY AND REDUCE COSTS USING CONTRINEX’S

EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS