(0121) 58 222 58 SALES@PLUSAUTOMATION.CO.UK

© 2021 - PLUS Automation Limited®

HELPING YOU #MAKE SENSE OF SENSORS

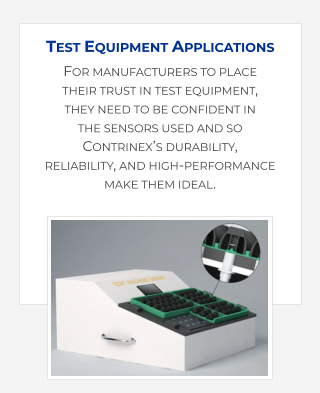

EXAMPLE APPLICATIONS

TO ILLUSTRATE THE WIDE-VARIETY OF APPLICATIONS SOLVED USING CONTRINEX SENSORS, WE HAVE POSTED A LARGE SELECTION OF EXAMPLE APPLICATIONS WHICH CAN BE SEEN BY CLICKING ON AN IMAGE. BELOW ARE A SELECTION OF SOME OF THESE APPLICATIONS:

CUSTOMER VALUES

INDUSTRY-STANDARD IO-LINK INTERFACE ENSURES

RELIABLE OUT-OF-THE-BOX CONNECTIVITY

TWO MODES OF OPERATION IN A SINGLE RWM PROVIDE

ULTIMATE FLEXIBILITY

STANDARD I/O MODE OPERATION SUPPORTS OPERATION OF

DECENTRALISED SORTING SYSTEMS

PLANT-WIDE IO-LINK HARDWARE SIMPLIFIES SYSTEM

INTEGRATION• COMMONALITY OF RWM HARDWARE

MINIMIZES SPARES INVENTORY HOLDING

INTEGRAL M12 CONNECTORS ENSURE EASY INSTALLATION

AND REPLACEMENT

PRODUCT ADVANTAGES

IO-LINK V1.1 COMPATIBILITY

ROBUST METAL HOUSINGS WITH PBTB SENSING FACES

SENSING DISTANCES UP TO 60MM

RECONFIGURABLE REMOTELY OR VIA MASTER TAG

SMART CONDITION-DETECTION SENSOR IN SIO MODE

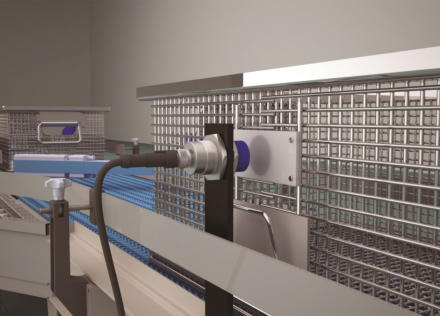

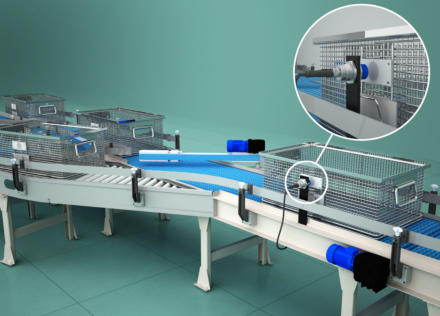

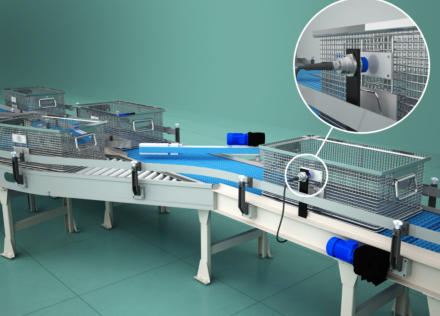

A manufacturer of automated conveyor systems uses RFID

technology to monitor the location of items and to route them

to their chosen destinations. As an basket, fitted with an RFID

transponder tag, travels through the warehouse, IO-Link-

enabled high-frequency read-write modules (RWMs) monitor

its position and read pre-set data stored in the tag. Local logic

capability enables a read-write module to trigger a conveyor

diverter, routing the item without reference to a centralised

PLC-based control system.

CUSTOMER APPLICATION

An OEM manufacturer of automated conveyor systems for the

distribution sector uses RFID technology to monitor the

location of items as they pass through a warehouse. Designers

also required local control of two-way conveyor diverters to

route items to the correct destination;. Therefore generic

information stored on each RFID transponder tag determines

the required diverter position and thus an item’s destination.

Location monitoring relies on a plant-wide PLC-based control

system. An industry-standard interface with the RFID modules

is highly desirable as this allows the use of existing libraries of

PLC function blocks, avoiding the need for custom PLC code.

Ultra-high-speed communication is not essential as conveyor

speeds are moderate.

Local diverter switching relies solely on the information

contained in an item’s RFID tag; communication with the

centralized system is unnecessary. Response time must be no

more than 200 milliseconds to allow the diverter to operate

before the item reaches the switch point.

THE CONVEYOR AND MATERIAL HANDLING INDUSTRY HAS LONG-TRUSTED CONTRINEX’S

INDUCTIVE SENSORS AND NOW WITH THE ADDITION OF WELL-PRICED PHOTOELECTRIC,

RFID AND MACHINE SAFETY SENSORS, MAKES CONTRINEX THE PERFECT MATCH.

CONVEYOR APPLICATIONS

CUSTOMER SOLUTION

IO-Link-enabled high-frequency (HF) read-write modules

(RWMs) and RFID tags from Contrinex are ideal for this

application. IO-Link-enabled RWMs are capable of meeting

both requirements, allowing commonality of RWM hardware

across the entire installation. With data-transfer rates up to

38.4k baud (COM2) in IO-Link mode, communication speeds

are well in excess of the minimum requirement.

Contrinex IO-Link RWMs are configurable to operate in one of

two discrete modes; IO-Link mode allows remote

communication via the standard protocol, while standard I/O

mode (SIO mode) allows the device to function as a smart

condition-detection sensor. Process engineers can switch

RWMs between modes either remotely, using

the IO-Link protocol itself, or locally, using a pre-configured

RFID tag (a Master Tag) which is applied directly in front of the

RWM at start-up.

While in SIO mode, RWMs operate either as simple presence-

detection sensors, with a single switched output, or as two-

state condition-detection sensors with two PNP outputs that

correspond to pre-set generic values saved to an item’s RFID.

In the event of a match, an RWM instructs a diverter to assume

one of two alternative switched positions.

With sensing distances up to 60mm, robust M18- and M30-

threaded metal housings and integral M12 connectors,

Contrinex RWMs are ideally suited to the environment of a

busy industrial warehouse. They are compatible with all

ISO/IEC 15693 approved RFID tags, allowing designers ultimate

flexibility and excellent value for money.

CUSTOMER VALUES

UNINTERRUPTED PRODUCTION AS POSITIONAL

IDENTIFICATION IS HIGHLY RELIABLE.

NO RISK OF SKEWING AS MOVEMENT OF THE MACHINE

STRUCTURE IS SYNCHRONISED.

ELIMINATION OF COLLISION DAMAGE BECAUSE OF SENSING

DISTANCE UP TO 45MM.

PRODUCT ADVANTAGES

PASSIVE RFID TRANSPONDER TAGS REQUIRE NO POWER

SOURCE AND MINIMAL MAINTENANCE.

RUGGED RFID TRANSPONDER TAGS WITH NYLON OR ALL-

METAL HOUSINGS SEALED TO IP67.

CONIDENT® TECHNOLOGY PROVIDES EXTENDED SENSING

RANGE ≤ 45MM.

READ/WRITE UNITS INTERFACE WITH A CHOICE OF INDUSTRY-

STANDARD CONTROL SYSTEMS OR IO-LINK

CUSTOMER SOLUTION

Contrinex high-frequency RFID read/write modules and

30mm-diameter RFID transponder tags are ideal for this

application. Rated up to IP67, the M30-diameter read/write

modules have PBTP sensing faces and V2A stainless-steel

housings, making them ideal for the demanding environment.

The ConIdent® passive transponders require no internal power

source and, with PBTP synthetic housings, have the same IP67

rating. The selected combination provides read/write distances

of up to 45mm (nearly 2 in), ideal for the specified operating

conditions. Tags are mounted at one-meter intervals along

each travel rail, each programmed with a unique identification

number.

As the machine passes a tag, the read/write module reads its

identification number at high speed; this is transmitted via a

PROFIBUS DP interface to the customer’s control system. A

simple look-up table confirms the location of the tag and thus

the position of the machine, allowing movement of both sides

of the structure to be synchronized without skewing.

Operation is independent of the direction of travel.

Contrinex ConIdent® RFID devices allow accurate and highly

reliable sensing of machine position and the long sensing

distance avoids any risk of collision damage. The customer

enjoys extended service life and robustness not available from

alternative position-detection systems, together with excellent

value for money

A manufacturer of bulk material-handling equipment uses

Contrinex Radio Frequency IDentification (RFID) technology to

sense the position of a large rail-mounted reclamation-

conveyor operating in a hot, dusty environment. A pair of read-

write modules, mounted on the machine structure,

interrogates a series of RFID tags, positioned at one-meter

intervals along each travel rail. The control system identifies

each tag individually and determines the exact position of the

machinery.

CUSTOMER APPLICATION

During surface-mining operations, large mobile reclamation

machines are used to recover bulk materials. On each

machine, a bucket-wheel excavator collects material and

deposits it onto a conveyor. As an area is cleared of material,

the machine moves along parallel steel travel rails to the next

area, allowing continuous operation without interruptions for

machine repositioning.

The distance between the travel rails is around 100 metres (300

ft) and travel speeds may reach 2m/sec (4.5 mph). If machine

movement along the two rails is not controlled accurately, the

two sides of the structure become misaligned, causing the

machine to skew. In this event, production is halted while the

machine is realigned; in the worst case, costly damage occurs.

A sensing system is required that detects the position of each

side of the machine structure accurately and reliably along the

entire length of the travel rails, allowing coordinated control of

the drive systems. Sensors must accommodate up to 10mm

lateral movement of the machine structure across either rail

and must withstand the hot, dusty environment of a desert

climate.

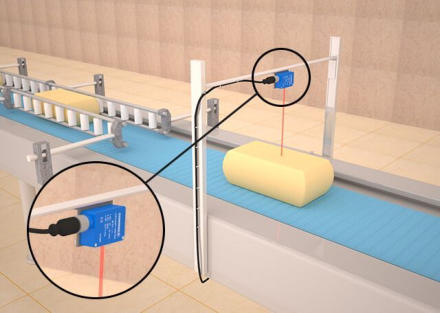

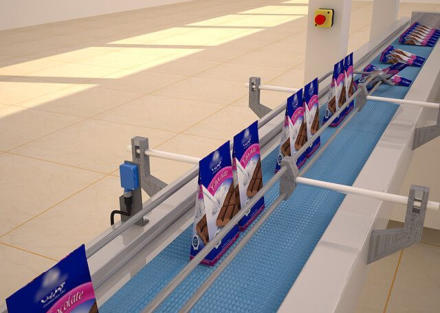

During the production of individually packaged cheese

portions, conveyors deliver product to packaging stations. In-

line buffering stations regulate flow to match packaging

throughput; miniature ECOLAB-certified sensors detect the

presence of each portion after buffering, triggering the

packaging cycle. Sensitivity parameters for each portion size,

stored on the sensor’s inbuilt memory, may be updated

remotely without manual intervention, eliminating the need

for unplanned sanitisation between batches.

CUSTOMER APPLICATION

A manufacturer of premium dairy products produces a range

of individually packaged cheese portions in a high-volume

hygienic production facility. Once cut to size, cheese portions

travel on a food-grade conveyor to a packaging station; the

duration of the packaging cycle is dependent on the type of

cheese and the portion size.

Prior to packaging, a buffering station produces a regular flow

of portions with a predetermined spacing to suit the

packaging throughput. The two operations must be

synchronized; the manufacturer requires a sensor system that

detects the presence of each cheese portion as it leaves the

buffering station, triggering the packaging cycle.

Sensors must be food-grade certified and withstand the

aggressive cleaning agents used during washdown routines.

They must also accommodate the full range of portion sizes

without the need for manual adjustment, as this would

necessitate sanitization each time the portion size changes.

Maximising throughput is an additional priority; rapid

changeover between product batches is essential.

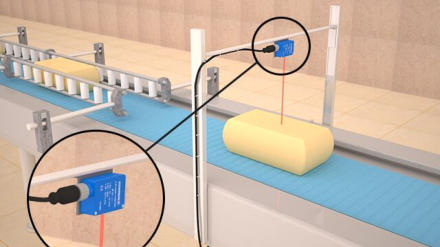

CUSTOMER SOLUTION

Ecolab-certified, diffuse-mode photoelectric sensors with

background suppression from the Contrinex C23 product

family are ideally suited to this application. These miniature

cubic devices, mounted above product conveyors immediately

after each buffering station, detect the presence of cheese

portions as they pass underneath. Positioning sensors is

simple thanks to a range of adjustable stainless steel

mounting brackets.

An industry-standard PNP normally open output with an M8

connector ensures optimum flexibility. Additionally, IO-Link, a

standardized point-to-point serial connection protocol for

sensors and actuators, is enabled on PNP versions at no

additional cost, offering the advantages of digital

communication without the need for special cabling. A second

output provides a stability alarm in the event of reduced

sensitivity, flagging the need for preventative maintenance

before any performance degradation occurs.

Robust sensor construction and Ecolab-certified miniature

(20mm x 30mm x 10mm) plastic housings which are corrosion-

resistant and impervious to water ingress ensure reliable

operation in the demanding washdown environment;

Contrinex C23 devices are rated to IP67. An operating range

between 15mm and 250mm, adjustable via a teach button or

via IO-Link, accommodates the range of portion sizes without

compromise.

A brief one- or two-step teach procedure simplifies initial set-

up. One-button operation allows process engineers to teach

the target object and, optionally, the background, each time a

new portion size is introduced. Once taught, sensitivity

parameters are stored on the sensor’s inbuilt memory and

may be retrieved or updated remotely via IO-Link, eliminating

the need for manual adjustment.

These rugged miniature sensors meet the customer’s need for

reliable operation with little or no manual intervention, while

unplanned sanitization is avoided. The solution is highly cost-

effective with minimal non-productive time; throughput is

maintained at or above target levels. An additional benefit of

offering a range of low-cost stainless-steel mounting and

protection bracketry.

CUSTOMER VALUES

Ecolab-certified sensors are ideal for hygienic

production facilities

Wide operating range accommodates full range of

portion sizes

Sensitivity parameters are retrieved or updated

remotely via IO-Link

Unnecessary sanitization between batches avoided

Simple one- or two-step teach procedure optimizes

initial sensor set-up

Stability alarm highlights reduced sensitivity,

avoiding unplanned stoppages

Downtime is avoided by eliminating the need for

technicians to attend machines

PRODUCT ADVANTAGES

Ecolab-certified photoelectric sensors with

background-suppression mode

IO-Link serial-connection protocol enabled on PNP

versions at no additional cost

Pre-taught sensitivity parameters stored on inbuilt

sensor memory

Remote sensitivity retrieval or update via IO-Link

Robust sensors with miniature (20mm x 30mm x

10mm) plastic housings

CUSTOMER VALUES

RELIABLE, REPEATABLE IN-LINE QUALITY CHECKS ON A NON-

CONTACT BASIS

IMPROVED QUALITY ARISING FROM REAL-TIME DETECTION OF

INCORRECTLY PACKED CARTONS

INCREASED PRODUCTIVITY AS STABILITY ALARM FLAGS

PREVENTATIVE-MAINTENANCE NEEDS• SINGLE SENSOR

ACCOMMODATES A RANGE OF CARTON SIZES WITHOUT

REPOSITIONING

REMOTE ADJUSTMENT VIA IO-LINK REDUCES CHANGEOVER

TIME BETWEEN PRODUCTS

PRODUCT ADVANTAGES

MAXIMUM SENSING RANGE OF 300MM WITH PINPOINT RED

LED

BEST-IN-CLASS BACKGROUND-SUPPRESSION BLACK/WHITE

BEHAVIOUR

IO-LINK CONNECTIVITY AVAILABLE AT NO EXTRA COST ON

PNP VERSIONS• DUAL OUTPUT WITH STABILITY ALARM

Contrinex’s C23 photoelectric sensor family is small but

powerful and so ideal for conveyor and packaging applications.

An example application for the C23 is the food processing

industry, where ‘shingling’, or overlapped layering, is a

common technique for optimizing space during secondary

packaging operations. As shown in the video, biscuits are

sealed in gusseted bags with a triangular profile, and packed

in alternating, overlapping layers into a preformed cardboard

box. Once each box is full, it passes to a case-sealing station

prior to palletisation and dispatch.

From time to time, an incorrectly formed layer occurs, where a

bag might be damaged or misaligned. The C23 photoelectric

sensor with Background Suppression is used to provide non-

contact sensing of the height of the top layer of bags, rejecting

any over-filled cartons.

CUSTOMER APPLICATION

In the food processing industry, shingling, or overlapped

layering, is a common technique for optimising space

utilisation during secondary packaging operations.

Confectionery, sealed in gusseted bags with predominantly

triangular profiles, is packed in alternating, overlapping layers

in preformed cardboard cartons. Once each carton is full, it

passes to a case-sealing station prior to palletisation and

dispatch.

Pre-aligned bags of confectionery arrive at the packing station

in regularly spaced rows. At each station, a multi-axis pick-and-

place packing robot lifts a row of bags, aligns it and lowers it

into a preformed carton. Successive layers overlap each other,

ensuring that space within the carton is fully utilised. Once the

predetermined number of layers has been packed, the carton

is conveyed to the sealing station.

From time to time, one or more incorrectly formed layers

occur. Individual bags may be missing from a row on arrival at

the packing station, or may be damaged or misaligned. A non-

contact sensor is needed to sense the height of the top layer of

bags, rejecting any defective cartons. It must be reliable and

require minimal maintenance.

CUSTOMER SOLUTION

A miniature through-beam photoelectric sensors from the

Contrinex C23 range are ideal for this application. These dual-

unit sensors, available with an optional alignment aid, have a

maximum sensing range of 30,000mm. Each sensor

comprises a separate transmitter and receiver, each mounted

in a 20mm x 30mm x 10mm miniature plastic housing;

connection to the control system is via a PVC-sheathed cable

with the choice of an integral M12 connector or a hermetically

sealed entry.

Immediately after each oven, a sensor is mounted with the

transmitter and receiver on opposite sides of the conveyor.

Depending on the space available around the oven, either unit

may be located some distance away from the track. The

integral alignment aid ensures rapid, accurate set-up, even at

extremes of operating range, while custom-designed

mounting brackets allow optimal sensor positioning in almost

any situation.

As each carton breaks the light beam, the sensor detects its

presence and signals the control system to increment the item

count. Industry-standard PNP or NPN, 3-wire or 4-wire outputs

support direct interfacing with modern industrial controls. A

second output provides a stability alarm in the event of

reduced sensitivity, flagging the need for preventative

maintenance before any performance degradation occurs. The

C23 range detects fast-moving targets reliably; remote

selection of switching frequency is possible via IO-Link, a

standardized point-to-point serial connection protocol,

available as standard at no extra cost for PNP versions.

During high-speed production of retail bags, a confectionery

manufacturer conveys individual bags of sweets to a pick-and-

place packing robot for secondary packaging. A highly reliable

diffuse-mode photoelectric sensor, mounted beside the

conveyor, detects the presence of bags as they approach the

packing station and inhibits the pick-and-place sequence if no

bags are queued for the packing robots.

CUSTOMER APPLICATION

In the food-processing industry, consumer products generally

require secondary packaging – both for consolidation and for

protection, before final dispatch. During confectionery

production, individual bags of sweets travel by conveyor from

bagging stations to a pick-and-place packing robot for

secondary packaging, before passing on to the labelling and

packing area.

Ideally, product flow along the conveyor is continuous; in

practice, interruptions occur from time to time as bagging

machines require attention. In the absence of bagged

products arriving at the secondary-packaging station, a plant-

wide control system prevents operation of the pick-and-place

robot to prevent miss-filling.

Immediately prior to arrival at the secondary-packaging

station, custom-formed guide rails align bags for packing.

Space is limited and there is no easy access to both sides of the

conveyor. A highly reliable non-contact sensor system was

needed to detect the presence of bags as they approach the

alignment rails; the system must inhibit the pick-and-place

sequence if no bags are queued for packing.

CUSTOMER VALUES

RELIABLE LONG-RANGE ITEM COUNTING ON A NON-CONTACT

BASIS

IMPROVED DATA ACCURACY ARISING FROM REAL-TIME,

ERROR-FREE PACK DETECTION

INCREASED PRODUCTIVITY AS STABILITY ALARM FLAGS

PREVENTATIVE-MAINTENANCE NEEDS

SINGLE SENSOR ACCOMMODATES A RANGE OF CARTON SIZES

WITHOUT REPOSITIONING

PRODUCT ADVANTAGES

MAXIMUM SENSING RANGE OF 30,000MM WITH INTEGRAL

ALIGNMENT AID

IO-LINK CONNECTIVITY AVAILABLE AT NO EXTRA COST ON

PNP VERSIONS

DUAL OUTPUT WITH STABILITY ALARM

VERSATILE, PURPOSE-DESIGNED MOUNTING BRACKETS FOR

EASE OF INSTALLATION

CUSTOMER SOLUTION

Rugged photoelectric sensors with background suppression

from the Contrinex C23 range are ideal for this application. A

pinpoint red LED with a 10mm-diameter light spot at the

maximum sensing range of 300mm ensures highly reliable

detection of objects of almost any colour against light or dark

backgrounds. These sensors are well suited to both the task

and the environment.

Immediately after packing, a single sensor is mounted

centrally above the conveyor. As each carton passes below on

its way to the sealing station, the sensor detects the top

surface of the packed bags. If the height of the top layer falls

outside preset limits, the sensor triggers a reject mechanism

that diverts the carton to a holding area for investigation.

Mounted in 20mm x 30mm x 10mm miniature plastic

housings, C23 photoelectric sensors are available with

industry-standard PNP or NPN 3-wire or 4-wire output.

Connection to the customer’s control system is via a PVC-

sheathed cable with the choice of an integral M12 connector or

a hermetically sealed entry. A second output provides a

stability alarm in the event of reduced sensitivity, flagging the

need for preventative maintenance before any performance

degradation occurs.

Locating sensors optimally is simple thanks to a custom-

designed range of multi-position mounting brackets. An

operating range between 15mm and 250mm accommodates a

variety of carton sizes without any need to reposition the

sensor. A simple electrical adjustment via an onboard

potentiometer suffices, while remote adjustment via IO-Link, a

standardized point-to-point serial connection protocol, is

available as standard at no extra cost for PNP version.

The sensors are corrosion-resistant and impervious to water

ingress and has the additional benefit of offering a range of

low-cost stainless-steel mounting and protection bracketry.

The reliability of the sensors in the application has been

excellent.

CUSTOMER SOLUTION

Diffuse-mode photoelectric sensors from the Contrinex C23PA

family of sensors are ideal for this application. These highly

reliable devices contain both a transmitter and a receiver and

do not require a separate reflector, instead relying on the

reflective nature of the target. Space constraints are

accommodated without compromise, thanks to a maximum

sensing range of 3 to 1500mm. This is adjustable via a pre-set

potentiometer or via IO-Link, the standardised point-to-point

serial connection protocol.

Immediately before the alignment rails, a single sensor is

mounted beside the conveyor; positioning sensors is simple

thanks to a range of adjustable mounting brackets. As each

bag passes in front of the sensor, its presence triggers the

device, sending a signal to the customer’s control system. A

high-intensity red LED with a 15mm-diameter light spot at the

selected 500mm sensing range ensures highly reliable

detection of bags in real-time.

Mounted in 20mm x 30mm x 10mm miniature plastic

housings, C23 photoelectric sensors are available with

industry-standard PNP or NPN 3-wire or 4-wire output.

Connection to the customer’s control system is via a PVC-

sheathed cable with the choice of an integral M12 connector or

a hermetically sealed entry. A second output provides a

stability alarm in the event of reduced sensitivity, flagging the

need for preventative maintenance before any performance

degradation occurs.

The sensors are corrosion-resistant and impervious to water

ingress and has the additional benefit of offering a range of

low-cost stainless-steel mounting and protection bracketry.

The reliability of the sensors in the application has been

excellent.

In a high-volume packaging operations conveyors deliver

stacked cartons to shrink-wrapping stations. At each station, a

wrapping machine encloses a stack in heat-shrink film and an

infrared oven shrinks the film to form a sealed pack of cartons.

A long-distance through-beam photoelectric sensor, mounted

beside the conveyor, senses the presence of each pack as it

leaves the oven and signals a plant-wide control system to

increment the production throughput totals.

CUSTOMER APPLICATION

In factories producing fast-moving consumer goods,

automated packaging operations are the norm. Confectionery

products are no exception; in high-volume production,

manufacturers pack sealed bags of candy in cardboard

cartons, which are in turn stacked for shrink- wrapping and

palletisation.

Packed cartons arrive for shrink-wrapping in uniform stacks. A

wrapping machine encloses each stack in a tube of heavy-duty

heat-shrink film; the stack then passes through an infrared

oven, where the film shrinks, forming a sealed pack of cartons.

After heat-shrinking, packs are conveyed to the consolidation

area for palletization.

Factory operators need to monitor production throughput for

each packaging line. Manual counting methods are

impractical and expensive. A highly reliable non-contact

sensor system is needed to detect the presence of each pack

as it leaves the shrink-wrapping area and to update the item

count held on a plant-wide control system. Long-distance

operation is desirable, as not all packaging lines are easily

accessible markings as cartons leave the printer-applicator,

rejecting any defective cartons.

A sensing range up to 30m, for Through-beam sensors

adjustable via a teach button or via IO-Link, accommodates a

wide range of machine geometries. Sensitivity parameters are

stored on the sensor’s inbuilt memory and may be retrieved or

updated remotely via IO-Link, eliminating the need for manual

adjustment.

These rugged miniature sensors meet the customer’s need for

reliable operation with little or no manual intervention, while

unplanned sanitisation is avoided. The solution is highly cost-

effective with minimal non-productive time; throughput is

maintained at or above target levels

CUSTOMER VALUES

RELIABLE, REPEATABLE IN-LINE QUALITY CHECKS ON A NON-

CONTACT BASIS

IMPROVED QUALITY ARISING FROM REAL-TIME DETECTION OF

INCORRECTLY PACKED CARTONS

INCREASED PRODUCTIVITY AS STABILITY ALARM FLAGS

PREVENTATIVE-MAINTENANCE NEEDS• SINGLE SENSOR

ACCOMMODATES A RANGE OF CARTON SIZES WITHOUT

REPOSITIONING

REMOTE ADJUSTMENT VIA IO-LINK REDUCES CHANGEOVER

TIME BETWEEN PRODUCTS

PRODUCT ADVANTAGES

MAXIMUM SENSING RANGE OF 300MM WITH PINPOINT RED

LED

BEST-IN-CLASS BACKGROUND-SUPPRESSION BLACK/WHITE

BEHAVIOUR

IO-LINK CONNECTIVITY AVAILABLE AT NO EXTRA COST ON

PNP VERSIONS• DUAL OUTPUT WITH STABILITY ALARM

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS, WE WILL WORK TO HELP YOU

SOLVE YOUR APPLICATIONS, IMPROVE MACHINE PERFORMANCE & RELIABILITY AND REDUCE COSTS

USING CONTRINEX’S EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

CONVEYOR APPLICATIONS

THE CONVEYOR AND MATERIAL HANDLING INDUSTRY

HAS LONG-TRUSTED CONTRINEX’S INDUCTIVE SENSORS

AND NOW WITH THE ADDITION OF WELL-PRICED

PHOTOELECTRIC, RFID AND MACHINE SAFETY

SENSORS, CONTRINEX, CONVEYORS AND MATERIAL

HANDLING ARE A PERFECT MATCH.

During the production of individually packaged cheese

portions, conveyors deliver product to packaging stations. In-

line buffering stations regulate flow to match packaging

throughput; miniature Ecolab-certified sensors detect the

presence of each portion after buffering, triggering the

packaging cycle. Sensitivity parameters for each portion size,

stored on the sensor’s inbuilt memory, may be updated

remotely without manual intervention, eliminating the need

for unplanned sanitisation between batches.

CUSTOMER APPLICATION

A Swiss manufacturer of premium dairy products produces a

range of individually packaged cheese portions in a high-

volume hygienic production facility. Once cut to size, cheese

portions travel on a food-grade conveyor to a packaging

station; the duration of the packaging cycle is dependent on

the type of cheese and the portion size.

Prior to packaging, a buffering station produces a regular flow

of portions with a predetermined spacing to suit the

packaging throughput. The two operations must be

synchronized; the manufacturer requires a sensor system that

detects the presence of each cheese portion as it leaves the

buffering station, triggering the packaging cycle.

Sensors must be food-grade certified and withstand the

aggressive cleaning agents used during washdown routines.

They must also accommodate the full range of portion sizes

without the need for manual adjustment, as this would

necessitate sanitization each time the portion size changes.

Maximising throughput is an additional priority; rapid

changeover between product batches is essential.

From time to time, one or more incorrectly formed layers

occur. Individual bags may be missing from a row on arrival at

the packing station, or may be damaged or misaligned. A non-

contact sensor is needed to sense the height of the top layer of

bags, rejecting any defective cartons. It must be reliable and

require minimal maintenance.

CUSTOMER SOLUTION

ECOLAB certified, diffuse-mode photoelectric sensors with

background suppression from the Contrinex C23 product

family are ideally suited to this application. These miniature

cubic devices, mounted above product conveyors immediately

after each buffering station, detect the presence of cheese

portions as they pass underneath. Positioning sensors is

simple thanks to a range of adjustable stainless steel

mounting brackets.

An industry-standard PNP normally open output with an M8

connector ensures optimum flexibility. Additionally, IO-Link, a

standardized point-to-point serial connection protocol for

sensors and actuators, is enabled on PNP versions at no

additional cost, offering the advantages of digital

communication without the need for special cabling. A second

output provides a stability alarm in the event of reduced

sensitivity, flagging the need for preventative maintenance

before any performance degradation occurs.

Robust sensor construction and ECOLAB-certified miniature

(20mm x 30mm x 10mm) plastic housings which are corrosion-

resistant and impervious to water ingress ensure reliable

operation in the demanding washdown environment;

Contrinex C23 devices are rated to IP67. An operating range

between 15mm and 250mm, adjustable via a teach button or

via IO-Link, accommodates the range of portion sizes without

compromise.

A brief one- or two-step teach procedure simplifies initial set-

up. One-button operation allows process engineers to teach

the target object and, optionally, the background, each time a

new portion size is introduced. Once taught, sensitivity

parameters are stored on the sensor’s inbuilt memory and

may be retrieved or updated remotely via IO-Link, eliminating

the need for manual adjustment.

These rugged miniature sensors meet the customer’s need for

reliable operation with little or no manual intervention, while

unplanned sanitization is avoided. The solution is highly cost-

effective with minimal non-productive time; throughput is

maintained at or above target levels. An additional benefit of

offering a range of low-cost stainless-steel mounting and

protection bracketry.

CUSTOMER VALUES

RELIABLE, REPEATABLE IN-LINE QUALITY CHECKS ON A NON-

CONTACT BASIS

IMPROVED QUALITY ARISING FROM REAL-TIME DETECTION OF

INCORRECTLY PACKED CARTONS

INCREASED PRODUCTIVITY AS STABILITY ALARM FLAGS

PREVENTATIVE-MAINTENANCE NEEDS

SINGLE SENSOR ACCOMMODATES A RANGE OF CARTON SIZES

WITHOUT REPOSITIONING

REMOTE ADJUSTMENT VIA IO-LINK REDUCES CHANGEOVER

TIME BETWEEN PRODUCTS

PRODUCT ADVANTAGES

MAXIMUM SENSING RANGE OF 300MM WITH PINPOINT RED

LED

BEST-IN-CLASS BACKGROUND-SUPPRESSION BLACK/WHITE

BEHAVIOUR

IO-LINK CONNECTIVITY AVAILABLE AT NO EXTRA COST ON

PNP VERSIONS

DUAL OUTPUT WITH STABILITY ALARM

CUSTOMER VALUES

INDUSTRY-STANDARD IO-LINK INTERFACE ENSURES

RELIABLE OUT-OF-THE-BOX CONNECTIVITY

TWO MODES OF OPERATION IN A SINGLE RWM PROVIDE

ULTIMATE FLEXIBILITY

STANDARD I/O MODE OPERATION SUPPORTS OPERATION OF

DECENTRALISED SORTING SYSTEMS

PLANT-WIDE IO-LINK HARDWARE SIMPLIFIES SYSTEM

INTEGRATION• COMMONALITY OF RWM HARDWARE

MINIMIZES SPARES INVENTORY HOLDING

INTEGRAL M12 CONNECTORS ENSURE EASY INSTALLATION

AND REPLACEMENT

PRODUCT ADVANTAGES

IO-LINK V1.1 COMPATIBILITY

ROBUST METAL HOUSINGS WITH PBTB SENSING FACES

SENSING DISTANCES UP TO 60MM

RECONFIGURABLE REMOTELY OR VIA MASTER TAG

SMART CONDITION-DETECTION SENSOR IN SIO MODE

A manufacturer of automated conveyor systems uses RFID

technology to monitor the location of items and to route them

to their chosen destinations. As an basket, fitted with an RFID

transponder tag, travels through the warehouse, IO-Link-

enabled high-frequency read-write modules (RWMs) monitor

its position and read pre-set data stored in the tag.

Local logic capability enables a read-write module to trigger a

conveyor diverter, routing the item without reference to a

centralised PLC-based control system.

CUSTOMER APPLICATION

An OEM manufacturer of automated conveyor systems for the

distribution sector uses RFID technology to monitor the

location of items as they pass through a warehouse. Designers

also required local control of two-way conveyor diverters to

route items to the correct destination;. Therefore generic

information stored on each RFID transponder tag determines

the required diverter position and thus an item’s destination.

Location monitoring relies on a plant-wide PLC-based control

system. An industry-standard interface with the RFID modules

is highly desirable as this allows the use of existing libraries of

PLC function blocks, avoiding the need for custom PLC code.

Ultra-high-speed communication is not essential as conveyor

speeds are moderate.

Local diverter switching relies solely on the information

contained in an item’s RFID tag; communication with the

centralized system is unnecessary. Response time must be no

more than 200 milliseconds to allow the diverter to operate

before the item reaches the switch point.

CUSTOMER SOLUTION

IO-Link-enabled high-frequency (HF) read-write modules

(RWMs) and RFID tags from Contrinex are ideal for this

application. IO-Link-enabled RWMs are capable of meeting

both requirements, allowing commonality of RWM hardware

across the entire installation. With data-transfer rates up to

38.4k baud (COM2) in IO-Link mode, communication speeds

are well in excess of the minimum requirement.

Contrinex IO-Link RWMs are configurable to operate in one of

two discrete modes; IO-Link mode allows remote

communication via the standard protocol, while standard I/O

mode (SIO mode) allows the device to function as a smart

condition-detection sensor. Process engineers can switch

RWMs between modes either remotely, using

the IO-Link protocol itself, or locally, using a pre-configured

RFID tag (a Master Tag) which is applied directly in front of the

RWM at start-up.

While in SIO mode, RWMs operate either as simple presence-

detection sensors, with a single switched output, or as two-

state condition-detection sensors with two PNP outputs that

correspond to pre-set generic values saved to an item’s RFID.

In the event of a match, an RWM instructs a diverter to assume

one of two alternative switched positions.

With sensing distances up to 60mm, robust M18- and M30-

threaded metal housings and integral M12 connectors,

Contrinex RWMs are ideally suited to the environment of a

busy industrial warehouse. They are compatible with all

ISO/IEC 15693 approved RFID tags, allowing designers ultimate

flexibility and excellent value for money.

CUSTOMER VALUES

UNINTERRUPTED PRODUCTION AS POSITIONAL

IDENTIFICATION IS HIGHLY RELIABLE.

NO RISK OF SKEWING AS MOVEMENT OF THE MACHINE

STRUCTURE IS SYNCHRONISED.

ELIMINATION OF COLLISION DAMAGE BECAUSE OF SENSING

DISTANCE UP TO 45MM.

PRODUCT ADVANTAGES

PASSIVE RFID TRANSPONDER TAGS REQUIRE NO POWER

SOURCE AND MINIMAL MAINTENANCE.

RUGGED RFID TRANSPONDER TAGS WITH NYLON OR ALL-

METAL HOUSINGS SEALED TO IP67.

CONIDENT® TECHNOLOGY PROVIDES EXTENDED SENSING

RANGE ≤ 45MM.

READ/WRITE UNITS INTERFACE WITH A CHOICE OF INDUSTRY-

STANDARD CONTROL SYSTEMS OR IO-LINK

CUSTOMER SOLUTION

Contrinex high-frequency RFID read/write modules and

30mm-diameter RFID transponder tags are ideal for this

application. Rated up to IP67, the M30-diameter read/write

modules have PBTP sensing faces and V2A stainless-steel

housings, making them ideal for the demanding environment.

The ConIdent® passive transponders require no internal power

source and, with PBTP synthetic housings, have the same IP67

rating. The selected combination provides read/write distances

of up to 45mm (nearly 2 in), ideal for the specified operating

conditions. Tags are mounted at one-meter intervals along

each travel rail, each programmed with a unique identification

number.

As the machine passes a tag, the read/write module reads its

identification number at high speed; this is transmitted via a

PROFIBUS DP interface to the customer’s control system. A

simple look-up table confirms the location of the tag and thus

the position of the machine, allowing movement of both sides

of the structure to be synchronized without skewing.

Operation is independent of the direction of travel.

Contrinex ConIdent® RFID devices allow accurate and highly

reliable sensing of machine position and the long sensing

distance avoids any risk of collision damage. The customer

enjoys extended service life and robustness not available from

alternative position-detection systems, together with excellent

value for money

A manufacturer of bulk material-handling equipment uses

Contrinex Radio Frequency IDentification (RFID) technology to

sense the position of a large rail-mounted reclamation-

conveyor operating in a hot, dusty environment. A pair of read-

write modules, mounted on the machine structure,

interrogates a series of RFID tags, positioned at one-meter

intervals along each travel rail. The control system identifies

each tag individually and determines the exact position of the

machinery.

CUSTOMER APPLICATION

During surface-mining operations, large mobile reclamation

machines are used to recover bulk materials. On each

machine, a bucket-wheel excavator collects material and

deposits it onto a conveyor. As an area is cleared of material,

the machine moves along parallel steel travel rails to the next

area, allowing continuous operation without interruptions for

machine repositioning.

The distance between the travel rails is around 100 metres (300

ft) and travel speeds may reach 2m/sec (4.5 mph). If machine

movement along the two rails is not controlled accurately, the

two sides of the structure become misaligned, causing the

machine to skew. In this event, production is halted while the

machine is realigned; in the worst case, costly damage occurs.

A sensing system is required that detects the position of each

side of the machine structure accurately and reliably along he

entire length of the travel rails, allowing coordinated control of

the drive systems. Sensors must accommodate up to 10mm

lateral movement of the machine structure across either rail

and must withstand the hot, dusty environment of a desert

climate.

CUSTOMER VALUES

RELIABLE, REPEATABLE IN-LINE QUALITY CHECKS ON A NON-

CONTACT BASIS

IMPROVED QUALITY ARISING FROM REAL-TIME DETECTION OF

INCORRECTLY PACKED CARTONS

INCREASED PRODUCTIVITY AS STABILITY ALARM FLAGS

PREVENTATIVE-MAINTENANCE NEEDS• SINGLE SENSOR

ACCOMMODATES A RANGE OF CARTON SIZES WITHOUT

REPOSITIONING

REMOTE ADJUSTMENT VIA IO-LINK REDUCES CHANGEOVER

TIME BETWEEN PRODUCTS

PRODUCT ADVANTAGES

MAXIMUM SENSING RANGE OF 300MM WITH PINPOINT RED

LED

BEST-IN-CLASS BACKGROUND-SUPPRESSION BLACK/WHITE

BEHAVIOUR

IO-LINK CONNECTIVITY AVAILABLE AT NO EXTRA COST ON

PNP VERSIONS• DUAL OUTPUT WITH STABILITY ALARM

Contrinex’s C23 photoelectric sensor family is small but

powerful and so ideal for conveyor and packaging applications.

An example application for the C23 is the food processing

industry, where ‘shingling’, or overlapped layering, is a

common technique for optimizing space during secondary

packaging operations. As shown in the video, biscuits are

sealed in gusseted bags with a triangular profile, and packed

in alternating, overlapping layers into a preformed cardboard

box. Once each box is full, it passes to a case-sealing station

prior to palletisation and dispatch.

From time to time, an incorrectly formed layer occurs, where a

bag might be damaged or misaligned. The C23 photoelectric

sensor with Background Suppression is used to provide non-

contact sensing of the height of the top layer of bags, rejecting

any over-filled cartons.

CUSTOMER APPLICATION

In the food processing industry, shingling, or overlapped

layering, is a common technique for optimising space

utilisation during secondary packaging operations.

Confectionery, sealed in gusseted bags with predominantly

triangular profiles, is packed in alternating, overlapping layers

in preformed cardboard cartons. Once each carton is full, it

passes to a case-sealing station prior to palletisation and

dispatch.

Pre-aligned bags of confectionery arrive at the packing station

in regularly spaced rows. At each station, a multi-axis pick-and-

place packing robot lifts a row of bags, aligns it and lowers it

into a preformed carton. Successive layers overlap each other,

ensuring that space within the carton is fully utilised. Once the

predetermined number of layers has been packed, the carton

is conveyed to the sealing station.

From time to time, one or more incorrectly formed layers

occur. Individual bags may be missing from a row on arrival at

the packing station, or may be damaged or misaligned. A non-

contact sensor is needed to sense the height of the top layer of

bags, rejecting any defective cartons. It must be reliable and

require minimal maintenance.

CUSTOMER SOLUTION

A miniature through-beam photoelectric sensors from the

Contrinex C23 range are ideal for this application. These dual-

unit sensors, available with an optional alignment aid, have a

maximum sensing range of 30,000mm. Each sensor

comprises a separate transmitter and receiver, each mounted

in a 20mm x 30mm x 10mm miniature plastic housing;

connection to the control system is via a PVC-sheathed cable

with the choice of an integral M12 connector or a hermetically

sealed entry.

Immediately after each oven, a sensor is mounted with the

transmitter and receiver on opposite sides of the conveyor.

Depending on the space available around the oven, either unit

may be located some distance away from the track. The

integral alignment aid ensures rapid, accurate set-up, even at

extremes of operating range, while custom-designed

mounting brackets allow optimal sensor positioning in almost

any situation.

As each carton breaks the light beam, the sensor detects its

presence and signals the control system to increment the item

count. Industry-standard PNP or NPN, 3-wire or 4-wire outputs

support direct interfacing with modern industrial controls. A

second output provides a stability alarm in the event of

reduced sensitivity, flagging the need for preventative

maintenance before any performance degradation occurs. The

C23 range detects fast-moving targets reliably; remote

selection of switching frequency is possible via IO-Link, a

standardized point-to-point serial connection protocol,

available as standard at no extra cost for PNP versions.

CUSTOMER VALUES

RELIABLE LONG-RANGE ITEM COUNTING ON A NON-CONTACT

BASIS

IMPROVED DATA ACCURACY ARISING FROM REAL-TIME,

ERROR-FREE PACK DETECTION

INCREASED PRODUCTIVITY AS STABILITY ALARM FLAGS

PREVENTATIVE-MAINTENANCE NEEDS

SINGLE SENSOR ACCOMMODATES A RANGE OF CARTON SIZES

WITHOUT REPOSITIONING

PRODUCT ADVANTAGES

MAXIMUM SENSING RANGE OF 30,000MM WITH INTEGRAL

ALIGNMENT AID

IO-LINK CONNECTIVITY AVAILABLE AT NO EXTRA COST ON

PNP VERSIONS

DUAL OUTPUT WITH STABILITY ALARM

VERSATILE, PURPOSE-DESIGNED MOUNTING BRACKETS FOR

EASE OF INSTALLATION

CUSTOMER SOLUTION

Rugged photoelectric sensors with background suppression

from the Contrinex C23 range are ideal for this application. A

pinpoint red LED with a 10mm-diameter light spot at the

maximum sensing range of 300mm ensures highly reliable

detection of objects of almost any colour against light or dark

backgrounds. These sensors are well suited to both the task

and the environment.

Immediately after packing, a single sensor is mounted

centrally above the conveyor. As each carton passes below on

its way to the sealing station, the sensor detects the top

surface of the packed bags. If the height of the top layer falls

outside preset limits, the sensor triggers a reject mechanism

that diverts the carton to a holding area for investigation.

Mounted in 20mm x 30mm x 10mm miniature plastic

housings, C23 photoelectric sensors are available with

industry-standard PNP or NPN 3-wire or 4-wire output.

Connection to the customer’s control system is via a PVC-

sheathed cable with the choice of an integral M12 connector or

a hermetically sealed entry. A second output provides a

stability alarm in the event of reduced sensitivity, flagging the

need for preventative maintenance before any performance

degradation occurs.

Locating sensors optimally is simple thanks to a custom-

designed range of multi-position mounting brackets. An

operating range between 15mm and 250mm accommodates a

variety of carton sizes without any need to reposition the

sensor. A simple electrical adjustment via an onboard

potentiometer suffices, while remote adjustment via IO-Link, a

standardized point-to-point serial connection protocol, is

available as standard at no extra cost for PNP version.

In a high-volume packaging operations conveyors deliver

stacked cartons to shrink-wrapping stations. At each station, a

wrapping machine encloses a stack in heat-shrink film and an

infrared oven shrinks the film to form a sealed pack of cartons.

A long-distance through-beam photoelectric sensor, mounted

beside the conveyor, senses the presence of each pack as it

leaves the oven and signals a plant-wide control system to

increment the production throughput totals.

CUSTOMER APPLICATION

In factories producing fast-moving consumer goods,

automated packaging operations are the norm. Confectionery

products are no exception; in high-volume production,

manufacturers pack sealed bags of candy in cardboard

cartons, which are in turn stacked for shrink- wrapping and

palletization.

Packed cartons arrive for shrink-wrapping in uniform stacks. A

wrapping machine encloses each stack in a tube of heavy-duty

heat-shrink film; the stack then passes through an infrared

oven, where the film shrinks, forming a sealed pack of cartons.

After heat-shrinking, packs are conveyed to the consolidation

area for palletization.

Factory operators need to monitor production throughput for

each packaging line. Manual counting methods are

impractical and expensive. A highly reliable non-contact

sensor system is needed to detect the presence of each pack

as it leaves the shrink-wrapping area and to update the item

count held on a plant-wide control system. Long-distance

operation is desirable, as not all packaging lines are easily

accessible markings as cartons leave the printer-applicator,

rejecting any defective cartons.

A sensing range up to 30m, for Through-beam sensors

adjustable via a teach button or via IO-Link, accommodates a

wide range of machine geometries. Sensitivity parameters are

stored on the sensor’s inbuilt memory and may be retrieved or

updated remotely via IO-Link, eliminating the need for manual

adjustment.

These rugged miniature sensors meet the customer’s need for

reliable operation with little or no manual intervention, while

unplanned sanitisation is avoided. The solution is highly cost-

effective with minimal non-productive time; throughput is

maintained at or above target levels

During high-speed production of retail bags, a confectionery

manufacturer conveys individual bags of sweets to a pick-and-

place packing robot for secondary packaging. A highly reliable

diffuse-mode photoelectric sensor, mounted beside the

conveyor, detects the presence of bags as they approach the

packing station and inhibits the pick-and-place sequence if no

bags are queued for the packing robots.

CUSTOMER APPLICATION

In the food-processing industry, consumer products generally

require secondary packaging – both for consolidation and for

protection, before final dispatch. During confectionery

production, individual bags of sweets travel by conveyor from

bagging stations to a pick-and-place packing robot for

secondary packaging, before passing on to the labelling and

packing area.

Ideally, product flow along the conveyor is continuous; in

practice, interruptions occur from time to time as bagging

machines require attention. In the absence of bagged

products arriving at the secondary-packaging station, a plant-

wide control system prevents operation of the pick-and-place

robot to prevent miss-filling.

Immediately prior to arrival at the secondary-packaging

station, custom-formed guide rails align bags for packing.

Space is limited and there is no easy access to both sides of the

conveyor. A highly reliable non-contact sensor system was

needed to detect the presence of bags as they approach the

alignment rails; the system must inhibit the pick-and-place

sequence if no bags are queued for packing

CUSTOMER SOLUTION

Diffuse-mode photoelectric sensors from the Contrinex C23PA

family of sensors are ideal for this application. These highly

reliable devices contain both a transmitter and a receiver and

do not require a separate reflector, instead relying on the

reflective nature of the target. Space constraints are

accommodated without compromise, thanks to a maximum

sensing range of 3 to 1500mm. This is adjustable via a pre-set

potentiometer or via IO-Link, the standardised point-to-point

serial connection protocol.

Immediately before the alignment rails, a single sensor is

mounted beside the conveyor; positioning sensors is simple

thanks to a range of adjustable mounting brackets. As each

bag passes in front of the sensor, its presence triggers the

device, sending a signal to the customer’s control system. A

high-intensity red LED with a 15mm-diameter light spot at the

selected 500mm sensing range ensures highly reliable

detection of bags in real-time.

Mounted in 20mm x 30mm x 10mm miniature plastic

housings, C23 photoelectric sensors are available with

industry-standard PNP or NPN 3-wire or 4-wire output.

Connection to the customer’s control system is via a PVC-

sheathed cable with the choice of an integral M12 connector or

a hermetically sealed entry. A second output provides a

stability alarm in the event of reduced sensitivity, flagging the

need for preventative maintenance before any performance

degradation occurs

The sensors are corrosion-resistant and impervious to water

ingress and has the additional benefit of offering a range of

low-cost stainless-steel mounting and protection bracketry.

The reliability of the sensors in the application has been

excellent.

The sensors are corrosion-resistant and impervious to water

ingress and has the additional benefit of offering a range of

low-cost stainless-steel mounting and protection bracketry.

The reliability of the sensors in the application has been

excellent

CUSTOMER VALUES

RELIABLE, REPEATABLE IN-LINE QUALITY CHECKS ON A NON-

CONTACT BASIS

IMPROVED QUALITY ARISING FROM REAL-TIME DETECTION OF

INCORRECTLY PACKED CARTONS

INCREASED PRODUCTIVITY AS STABILITY ALARM FLAGS

PREVENTATIVE-MAINTENANCE NEEDS• SINGLE SENSOR

ACCOMMODATES A RANGE OF CARTON SIZES WITHOUT

REPOSITIONING

REMOTE ADJUSTMENT VIA IO-LINK REDUCES CHANGEOVER

TIME BETWEEN PRODUCTS

PRODUCT ADVANTAGES

MAXIMUM SENSING RANGE OF 300MM WITH PINPOINT RED

LED

BEST-IN-CLASS BACKGROUND-SUPPRESSION BLACK/WHITE

BEHAVIOUR

IO-LINK CONNECTIVITY AVAILABLE AT NO EXTRA COST ON

PNP VERSIONS• DUAL OUTPUT WITH STABILITY ALARM

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS,

WE WILL HELP YOU SOLVE YOUR APPLICATIONS, IMPROVE MACHINE

PERFORMANCE & RELIABILITY AND REDUCE COSTS USING CONTRINEX’S

EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS